Measuring device for determining fluid variable

A measurement device, fluid technology, applied in the direction of measurement device, fluid velocity measurement, vibration measurement in solids, etc., can solve the problems of complex photolithography, inability to achieve modal purity, inability to obtain high efficiency, etc., and achieve the effect of avoiding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

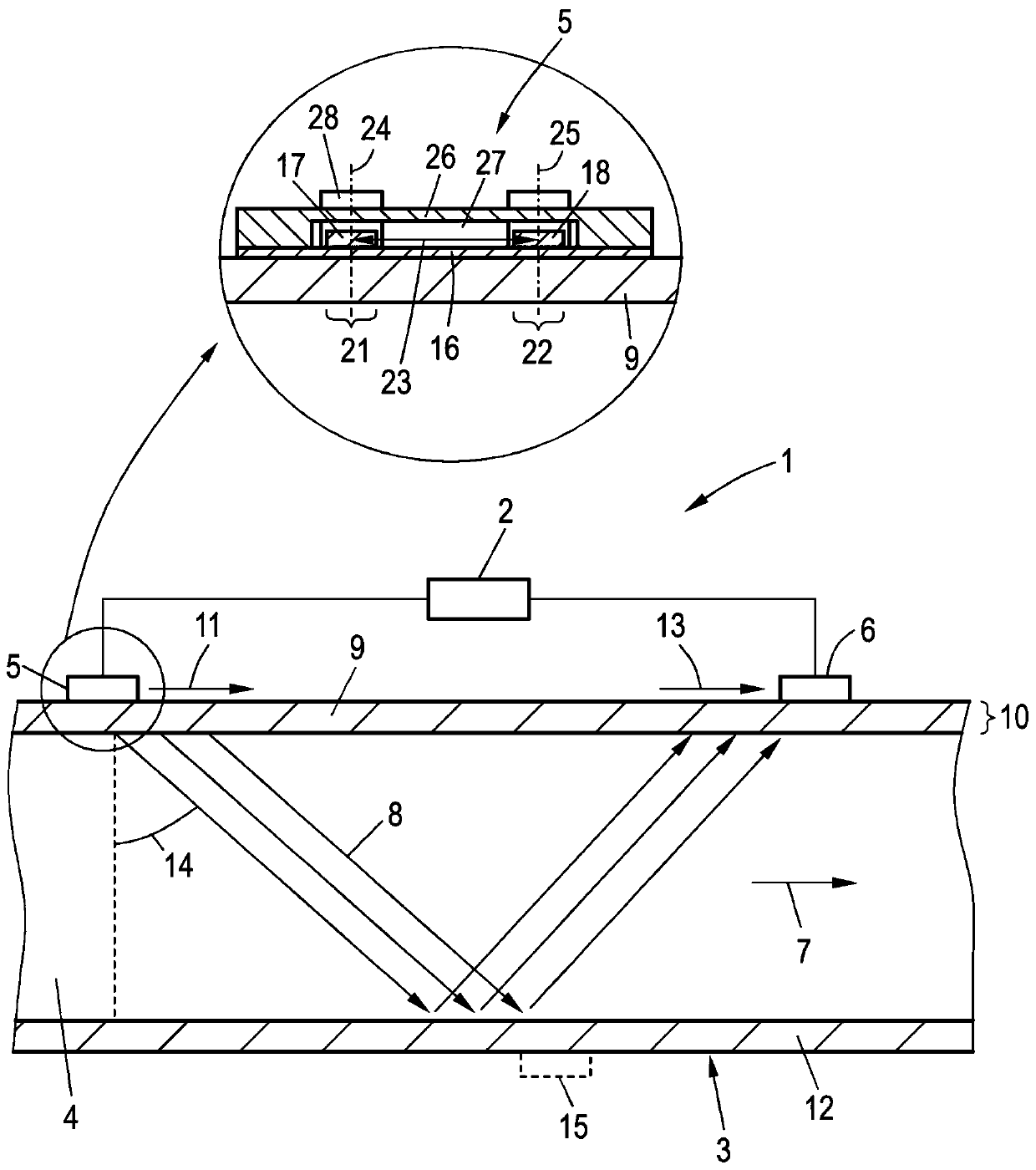

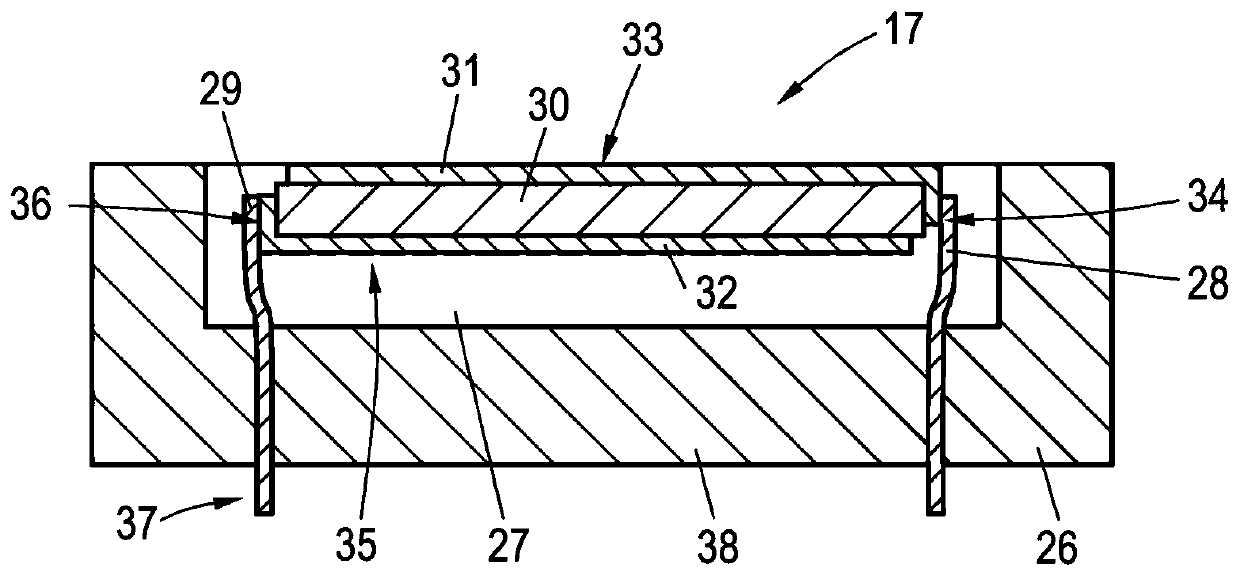

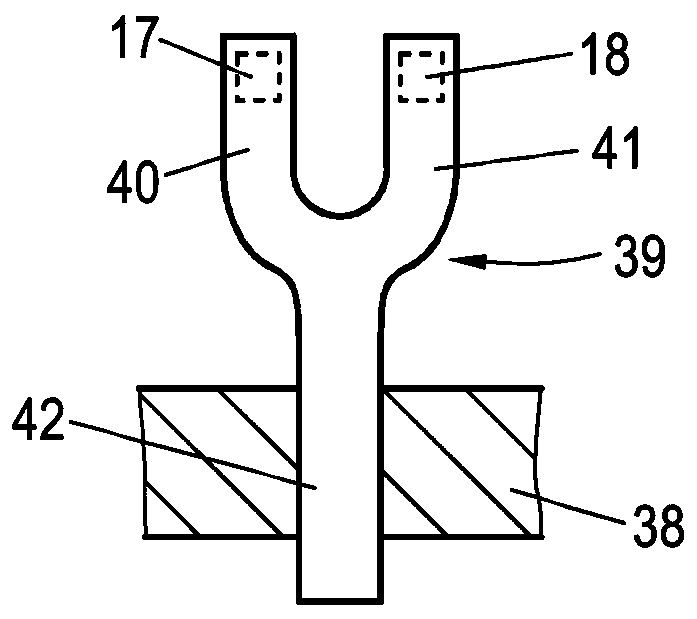

[0032] figure 1 A measuring device 1 for determining a fluid variable related to a fluid and / or fluid flow is shown. Here, the fluid is guided through the interior 4 of the measuring tube 3 in the direction indicated by the arrow 7 . In order to determine a fluid variable, in particular a volumetric flow rate, the control device 2 can determine from the first vibration transducer 5 to the second vibration transducer 6 and from the second vibration transducer 6 to the first vibration transducer 5 The transit time difference between the transit times of . Here, use is made of the fact that this transit time depends on the velocity component of the fluid parallel to the direction of propagation of the ultrasound beam 8 through the fluid. From this transit time the fluid velocity averaged over the path of the respective ultrasound beam 8 in the direction of the respective ultrasound beam 8 and thus approximately the average flow velocity in the volume through which the ultrasoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com