A shield opening method under pressure for strong air-permeable and water-permeable formations

A technology for shield belts and formations, which is applied in earthwork drilling, underground chambers, shaft equipment, etc., and can solve problems such as limited film formation, strength durability, water resistance, and limited range of formation reinforcement, and achieve high Promoting the effect of app value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

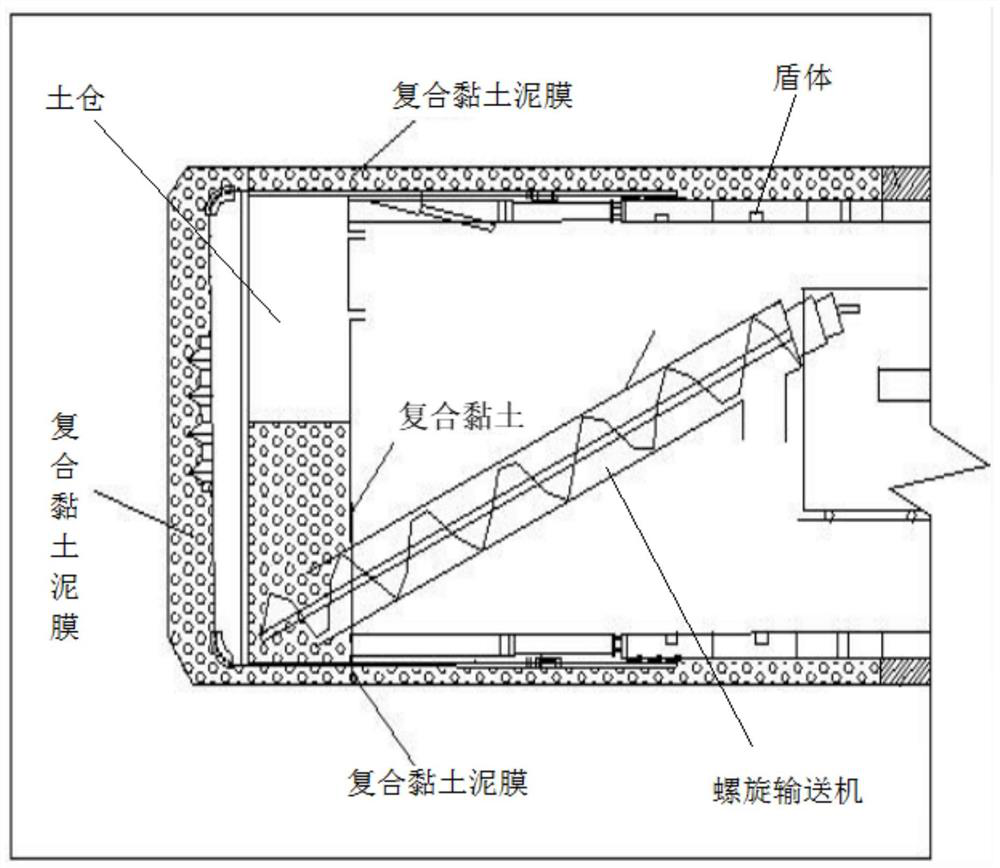

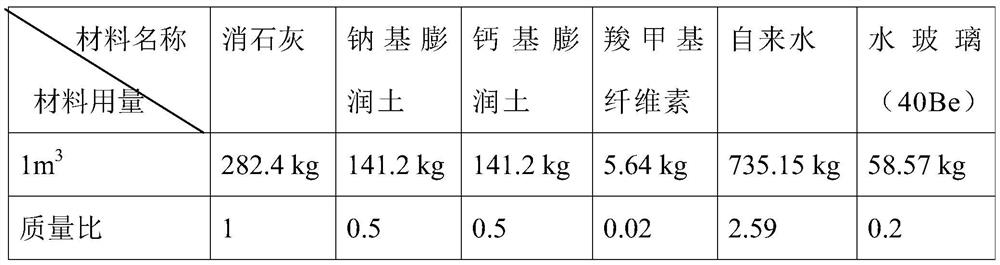

[0033] A shield tunneling method under pressure for strong air-permeable and water-permeable formations in this embodiment includes the following steps:

[0034] S1. It is planned to release the hinges of the 1~3 rings before the shield is shut down with pressure to open the bin gradually, and carry out the ring sealing operation on the fifth ring after the shield tail; among them, when releasing the hinges, the hinge length needs to be extended by 100mm for the follow-up knife The disk retreats to form a mud film to reserve space; when performing the ring sealing operation, inject 200kg of polyurethane into the shield, and use the second grouting double liquid slurry to seal the ring.

[0035] S2. Transport the bentonite slurry produced by the ground mortar mixing station into the tunnel, and then use the mortar pump to pump the bentonite slurry into the mortar tank of the shield machine.

[0036] S3. Add water glass with a design volume of 1 / 3 volume in the synchronous groutin...

Embodiment 2

[0049] A shield tunneling method under pressure for strong air-permeable and water-permeable formations in this embodiment includes the following steps:

[0050] S1. It is planned to release the hinges of the 1~3 rings before the shield is shut down with pressure to open the bin, and seal the fifth ring after the tail of the shield; among them, when releasing the hinges, the hinge length needs to be extended by 150mm for the follow-up knife The disk retreats to form a mud film to reserve space; during the ring sealing operation, 300kg of polyurethane is injected into the Zhongdun, and the ring is sealed with double-slurry grouting for the second time.

[0051] S2. Transport the bentonite slurry produced by the ground mortar mixing station into the tunnel, and then use the mortar pump to pump the bentonite slurry into the mortar tank of the shield machine.

[0052] S3. Add water glass with a design volume of 1 / 3 volume in the synchronous grouting box of the shield machine, and ...

Embodiment 3

[0065] A shield tunneling method under pressure for strong air-permeable and water-permeable formations in this embodiment includes the following steps:

[0066] S1. It is planned to release the hinges of the 1~3 rings before the shield is shut down with pressure to open the bin gradually, and carry out the ring sealing operation on the fifth ring behind the shield tail; among them, when releasing the hinges, the hinge length needs to be extended by 125mm for the subsequent knife The disk retreats to form a mud film to reserve space; during the ring sealing operation, 250kg of polyurethane is injected into the Zhongdun, and the ring is sealed with double-slurry grouting for the second time.

[0067] S2. Transport the bentonite slurry produced by the ground mortar mixing station into the tunnel, and then use the mortar pump to pump the bentonite slurry into the mortar tank of the shield machine.

[0068] S3. Add water glass with a design volume of 1 / 3 volume in the synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com