Uniformly distributed annular pressure sealing valve and sealing method

A technology of sealing valves and cloth rings, which is applied in the direction of engine sealing, valve devices, mechanical equipment, etc., can solve the problems of complex structural design of parts, poor sealing effect, small application range, etc., and achieve simple structure, guaranteed action, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

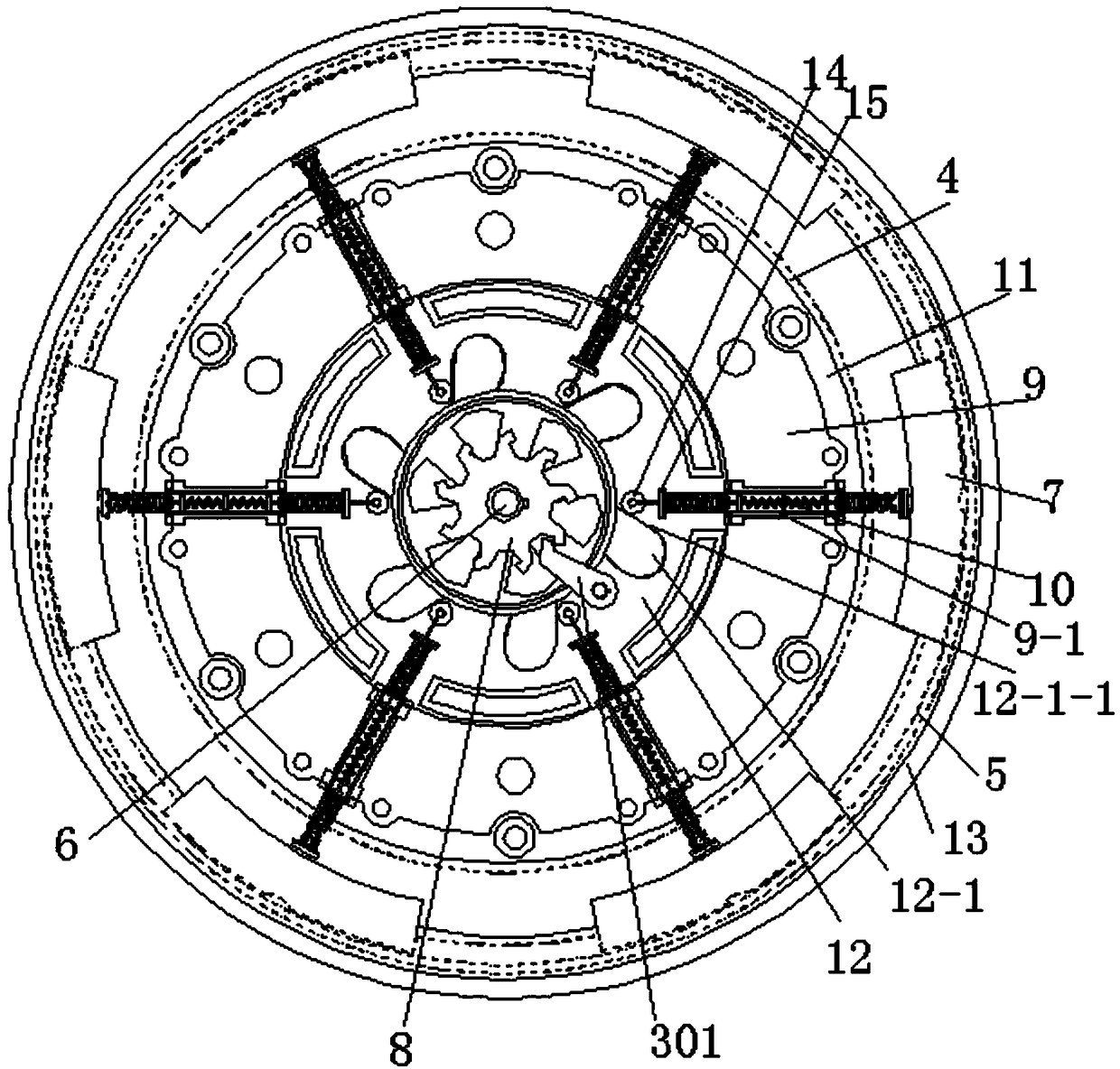

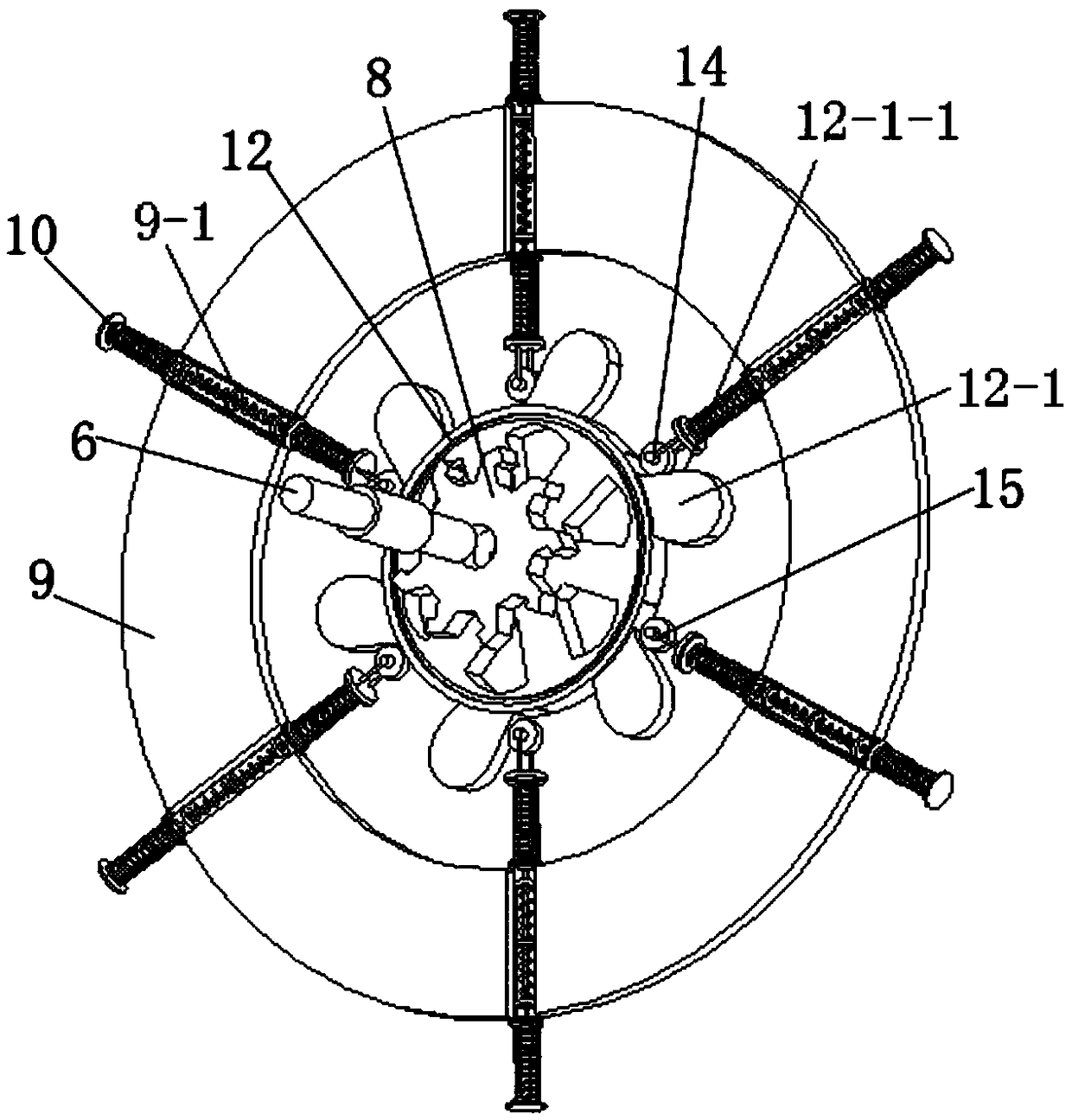

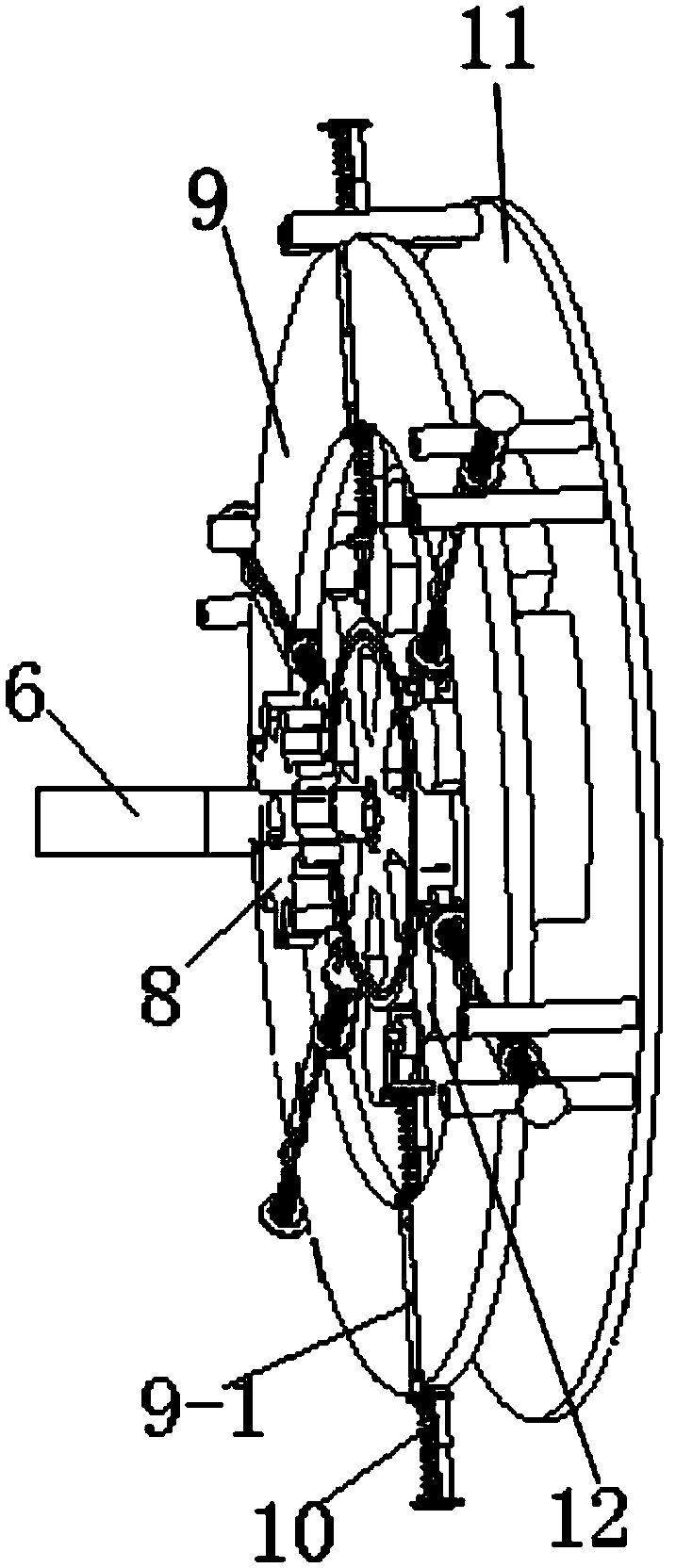

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as Figure 1-Figure 7 As shown, the uniformly distributed annular pressure sealing valve of the present invention includes a positioning disc 11, a sealing outer ring 13, an elastic pressing block 7 and a sealing inner ring 5. The axis of the positioning disc 11 is connected to a transmission shaft 6 in rotation, and The cam disc 12 that can rotate synchronously with the transmission shaft 6 is installed, and the center of the cam disc 12 is symmetrically distributed with six cam ends 12-1. The secondary elastic pressure rod 10 of the transmission rod is used for radial force transmission, the secondary elastic pressure rod 10 is arranged radially along the cam disc 12, and the positioning plate 11 is provided with a radial guide for the secondary elastic pressure rod 10. The guide device, the inner end of each secondary spring pressing rod 10 is set in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com