Fast shot energy accumulator valve group box of die-casting machine

A technology of accumulator and die-casting machine, which is applied in the field of die-casting machinery, can solve the problems of pressure-holding leakage and unstable pressure-holding of die-casting machines, and achieve the effect of safe pressure-holding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

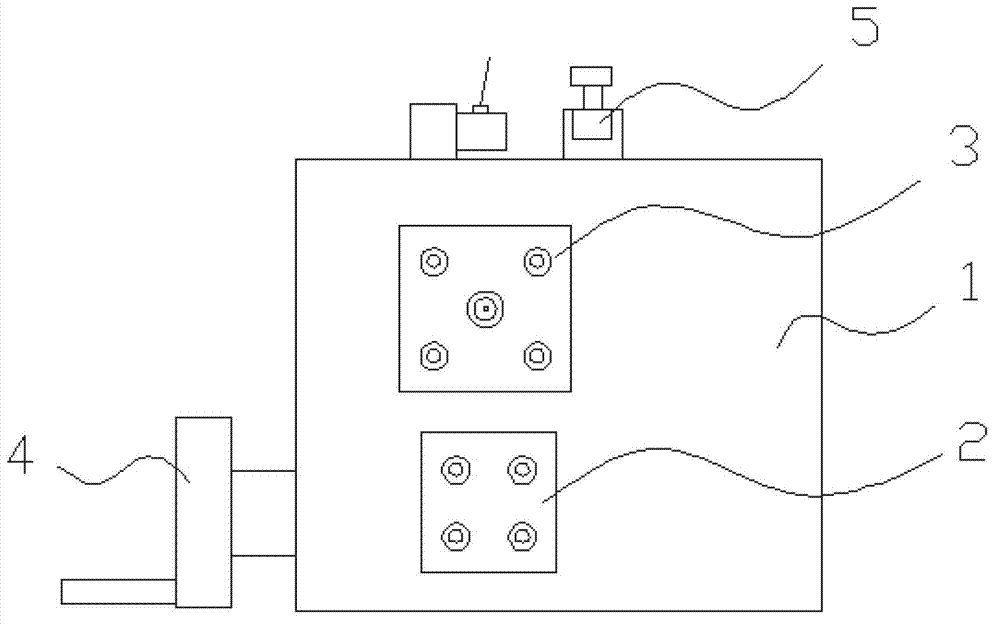

[0012] like figure 1 As shown, the quick injection accumulator valve group box of the die-casting machine includes a box body 1 and a two-way cartridge valve 2 arranged at the front lower part of the box body 1, and the quick injection accumulator valve group box of the die-casting machine also includes a device The electromagnetic valve 3 located above the two-way cartridge valve 2 on the front of the box body 1 is connected to the quick injection opening oil circuit. Two quick adjustment handwheels 4 are provided on the side of the casing 1 . The valve group box of the fast injection accumulator of the die-casting machine also includes a pressure reducing valve 5 arranged on the upper part of the box body 1, and the pressure reducing valve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com