Proportional pressure valve with air supply switch

A proportional pressure valve and switch technology, applied in the field of proportional pressure valve, can solve the problems of pressure regulation at any time, loose structure, large total volume, etc., and achieve the effect of convenient packaging and transportation, convenient use and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

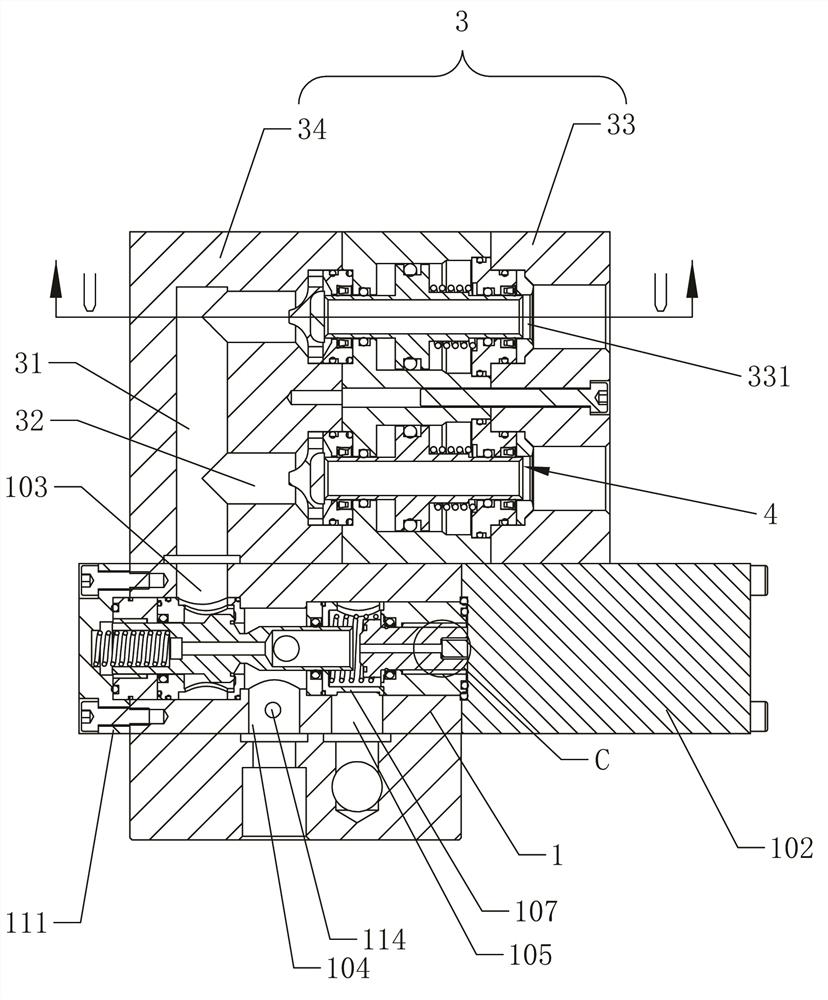

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

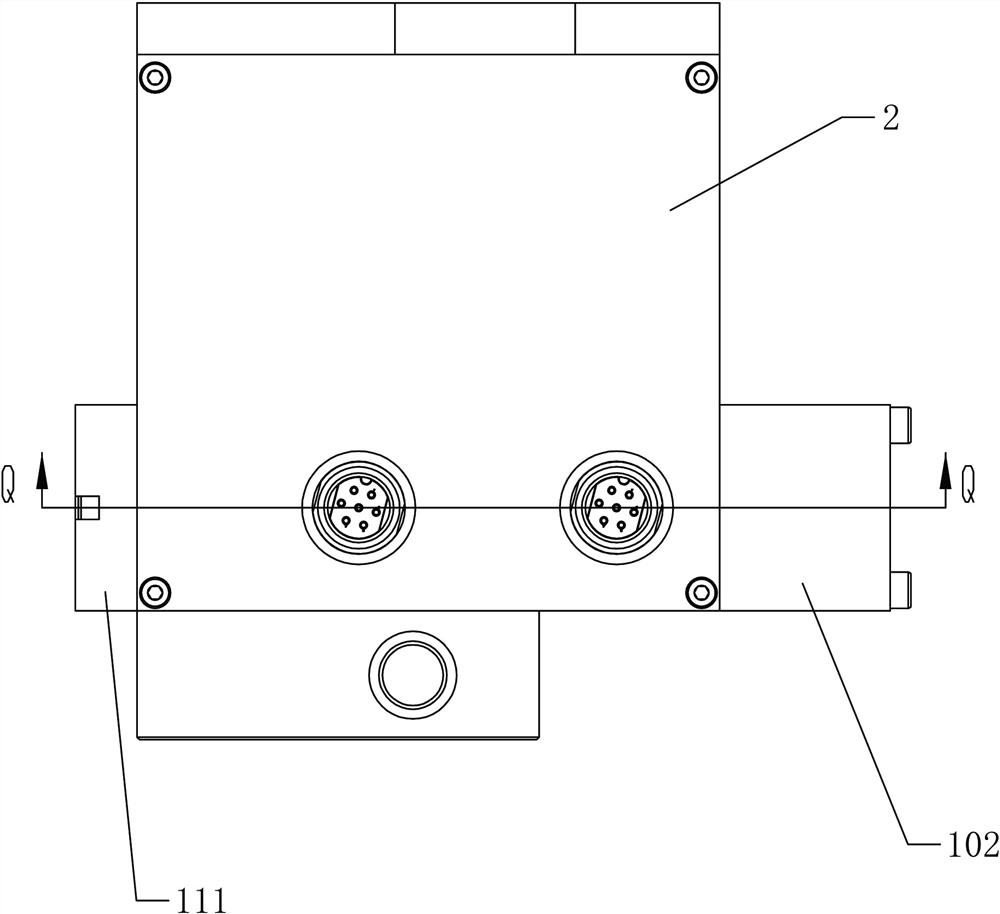

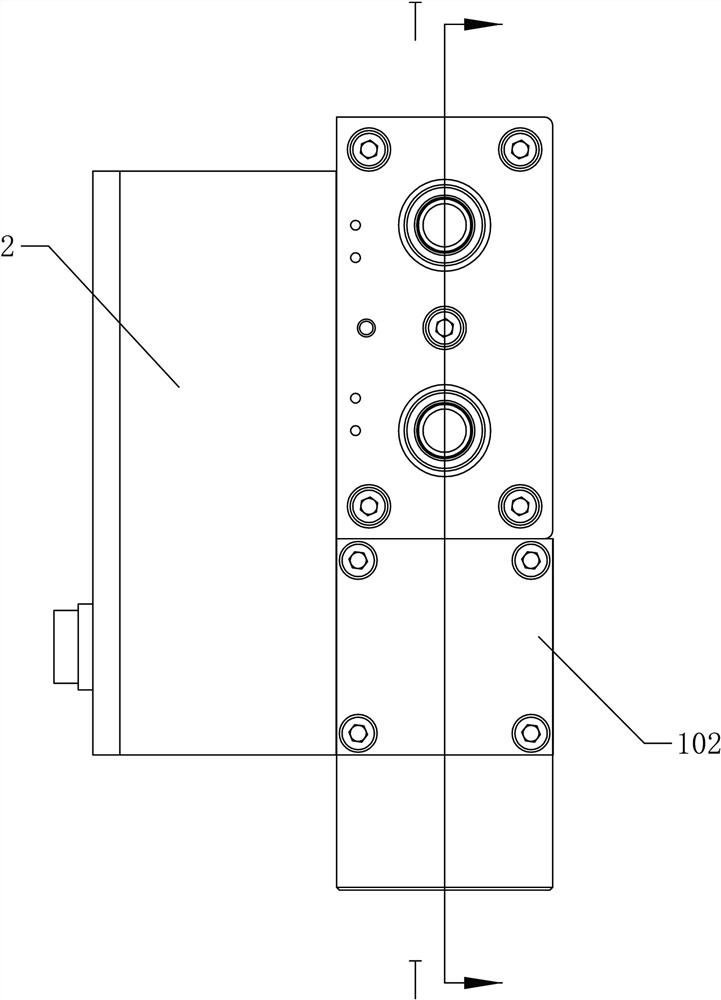

[0048] A proportional pressure valve with an air supply switch, such as Figure 1-4 , 7-9, it includes a main valve body 1 and a control module 2. One end of the main valve body 1 is provided with an electric control assembly and a push rod 101. The electric control assembly is set as a proportional electromagnet 102. When the proportional electromagnet 102 is energized At the same time, the relative telescopic movement of the push rod 101 can be controlled. The main valve body 1 is provided with an intake port 103, a working port 104 and an exhaust port 105, and the valve cavity of the main valve body 1 is also provided with an intermediate sealing seat 106 corresponding to the intake port 103 and a seal corresponding to the exhaust port 105. The exhaust spacer 107 and the intermediate seal seat 106 are provided with an air intake cavity 1061 which communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com