A kind of high-strength and high-toughness Cu-containing low-alloy high-strength steel and heat treatment method thereof

A high-strength, high-toughness, low-alloy technology is applied in the field of high-strength, high-toughness Cu-containing low-alloy high-strength steel and its heat treatment. It can solve problems such as poor matching of strength and toughness, and achieve easy implementation, good strength and toughness matching, and high impact toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

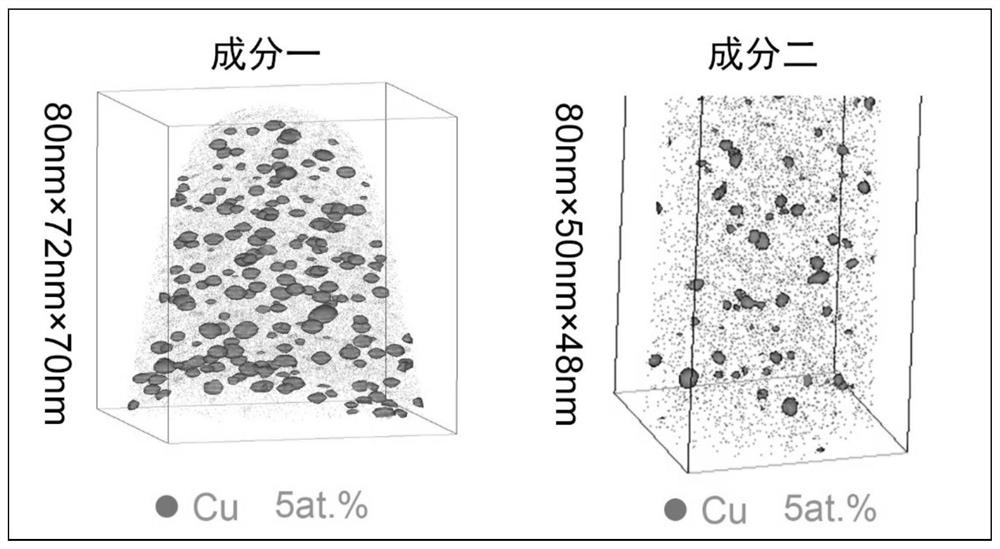

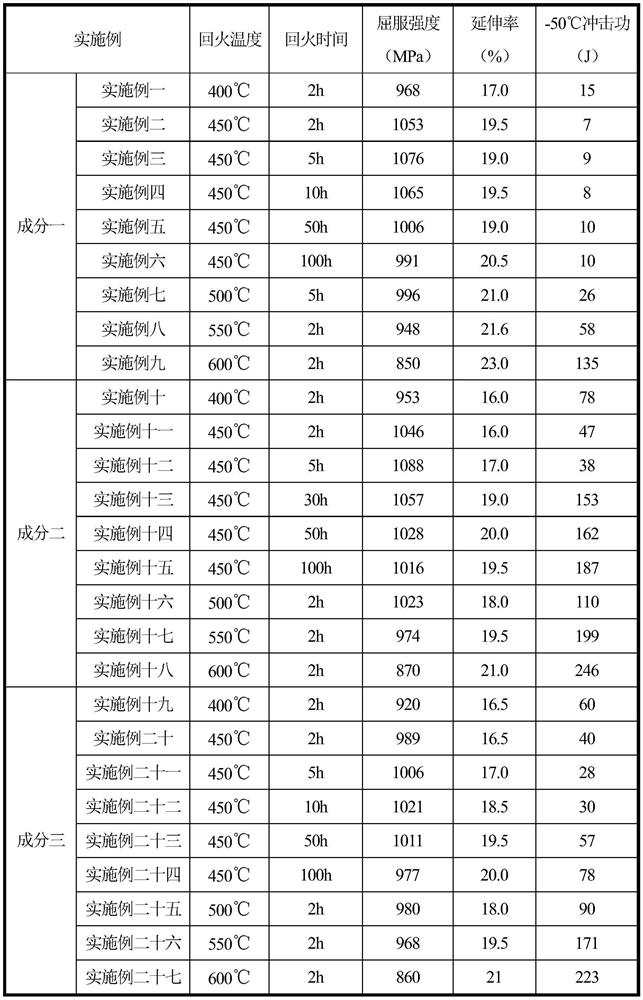

[0028] In a specific implementation process, the present invention achieves the purpose of controlling the precipitation behavior of nanometer Cu-rich clusters by adjusting the content of Mn element. After a suitable heat treatment process, a tempered martensite structure is obtained, and a large number of fine-sized Cu-rich clusters are dispersed, so that the alloy steel has a good strength-toughness matching. The heat treatment method is: ① first quenching treatment. The Cu-containing low-alloy high-strength steel is kept at 840-920° C. for 30-120 minutes and then water-quenched to room temperature to obtain lath martensite structure. At this time, Cu element is dissolved in the matrix. ②Tempering treatment. The quenched alloy steel is placed at 400-600° C., kept for 0.5-100 hours, and then water-cooled to room temperature to obtain a tempered martensite structure. During the tempering process, the Cu element solid-dissolved in the matrix will precipitate in the form of C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com