A method for separating low-grade fluorite-barite paragenetic ore rich in calcite

A separation method, barite technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems that flotation backwater cannot be recycled and the grade of fluorite concentrate is not high, so as to improve flotation Efficiency, increasing hydrophilicity, and reducing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

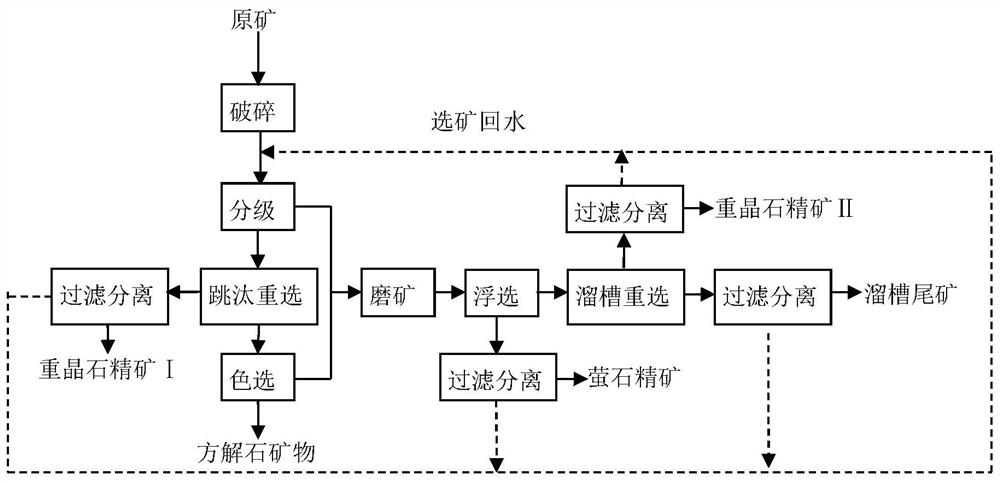

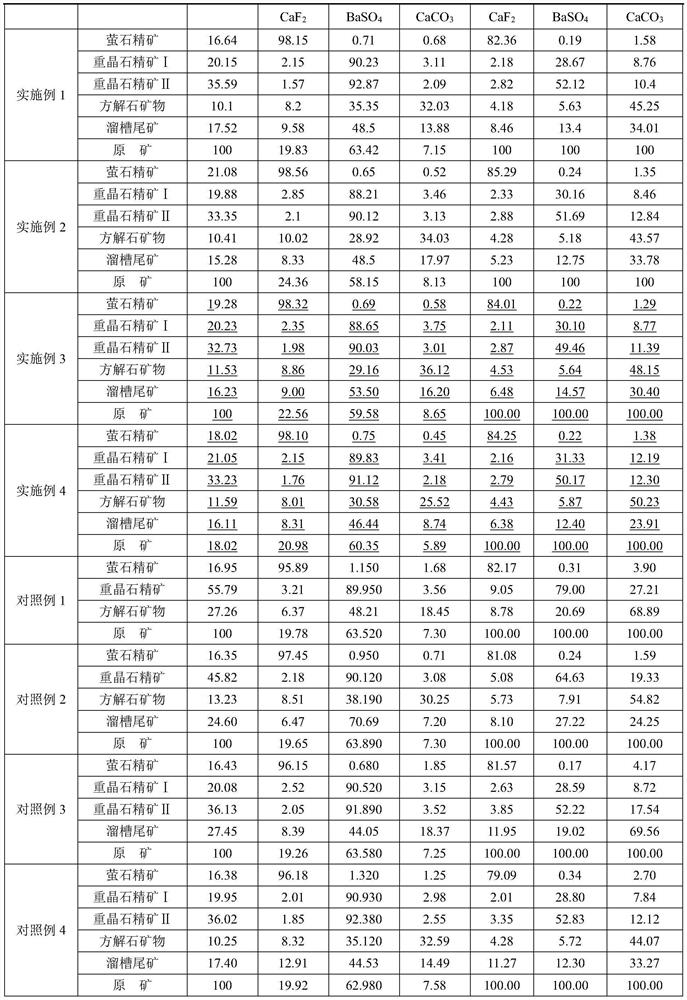

[0048] A low-grade fluorite-barite paragenetic ore rich in calcite, the original ore mainly contains CaF 2 19.83wt%, BaSO 4 63.42wt%, CaCO 3 7.15wt%, its separation method is as figure 1 shown, including the following steps:

[0049] S1. Use jaw crusher and cone crusher to crush the raw ore in two stages to obtain crushed ore with a particle size of -20mm;

[0050] S2. Classify the crushed ore to obtain fine-grained ore with a particle size of -1mm, medium-grained ore with a particle size of +1-8mm, and coarse-grained ore with a particle size of +8-20mm;

[0051] S3. Using a fine-grain jig to perform jigging gravity separation on the medium-grained ore to obtain the medium-grained concentrate and tailings I;

[0052] S4. Use a coarse-grained jig to perform jigging gravity separation on the coarse-grained ore to obtain the coarse-grained concentrate and tailings II;

[0053] S5. Merge the medium-sized ore concentrate and the coarse-grained ore concentrate to obtain BaSO-co...

Embodiment 2

[0061] A low-grade fluorite-barite paragenetic ore rich in calcite, the original ore mainly contains CaF 2 24.36 wt%, BaSO 4 58.15wt%, CaCO 3 8.13wt%, its separation method is as figure 1 shown, including the following steps:

[0062] S1. Use jaw crusher and cone crusher to crush the raw ore in two stages to obtain crushed ore with a particle size of -15mm;

[0063] S2. Classifying the broken ore to obtain fine-grained ore with a particle size of -1mm, medium-grained ore with a particle size of +1-5mm, and coarse-grained ore with a particle size of +5-15mm;

[0064] S3. Using a fine-grain jig to perform jigging gravity separation on the medium-grained ore to obtain the medium-grained concentrate and tailings I;

[0065] S4. Use a coarse-grained jig to perform jigging gravity separation on the coarse-grained ore to obtain the coarse-grained concentrate and tailings II;

[0066] S5. Merge the medium-sized ore concentrate and the coarse-grained ore concentrate to obtain BaSO...

Embodiment 3

[0074] A low-grade fluorite-barite paragenetic ore rich in calcite, the original ore mainly contains CaF 2 22.56wt%, BaSO 4 59.35wt%, CaCO 3 8.65wt%, its separation method is as figure 1 shown, including the following steps:

[0075] S1. Use jaw crusher and cone crusher to crush the raw ore in two stages to obtain crushed ore with a particle size of -15mm;

[0076] S2. Classifying the broken ore to obtain fine-grained ore with a particle size of -1mm, medium-grained ore with a particle size of +1-5mm, and coarse-grained ore with a particle size of +5-15mm;

[0077]S3. Using a fine-grain jig to perform jigging gravity separation on the medium-grained ore to obtain the medium-grained concentrate and tailings I;

[0078] S4. Use a coarse-grained jig to perform jigging gravity separation on the coarse-grained ore to obtain the coarse-grained concentrate and tailings II;

[0079] S5. Merge the medium-sized ore concentrate and the coarse-grained ore concentrate to obtain BaSO-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com