A polymer-based blend film, its preparation method and application

A technology of polymer and blended membranes, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of limited application range of polymer gas separation membranes, difficulty in achieving high permeability coefficient and high selectivity at the same time, etc. Achieve the effect of improving carbon dioxide separation performance, simple and easy method, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

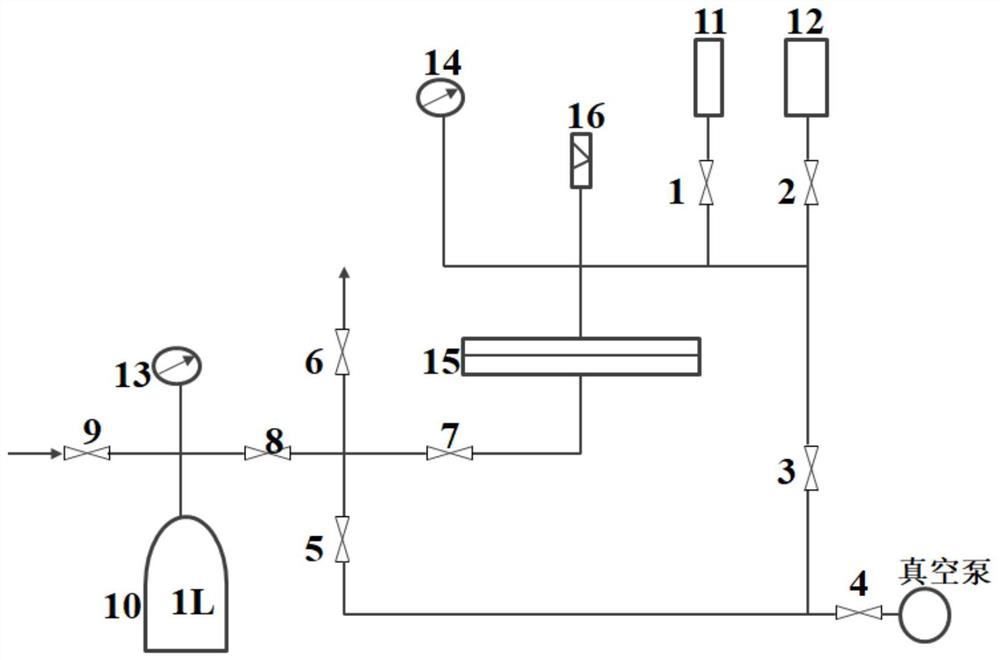

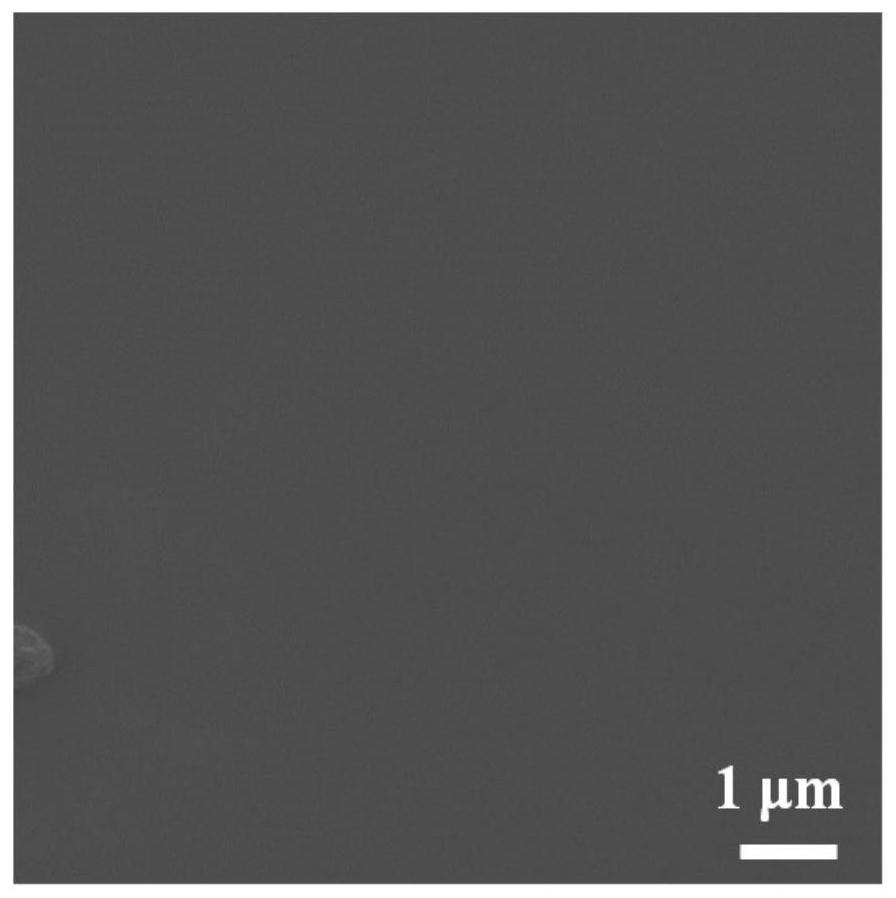

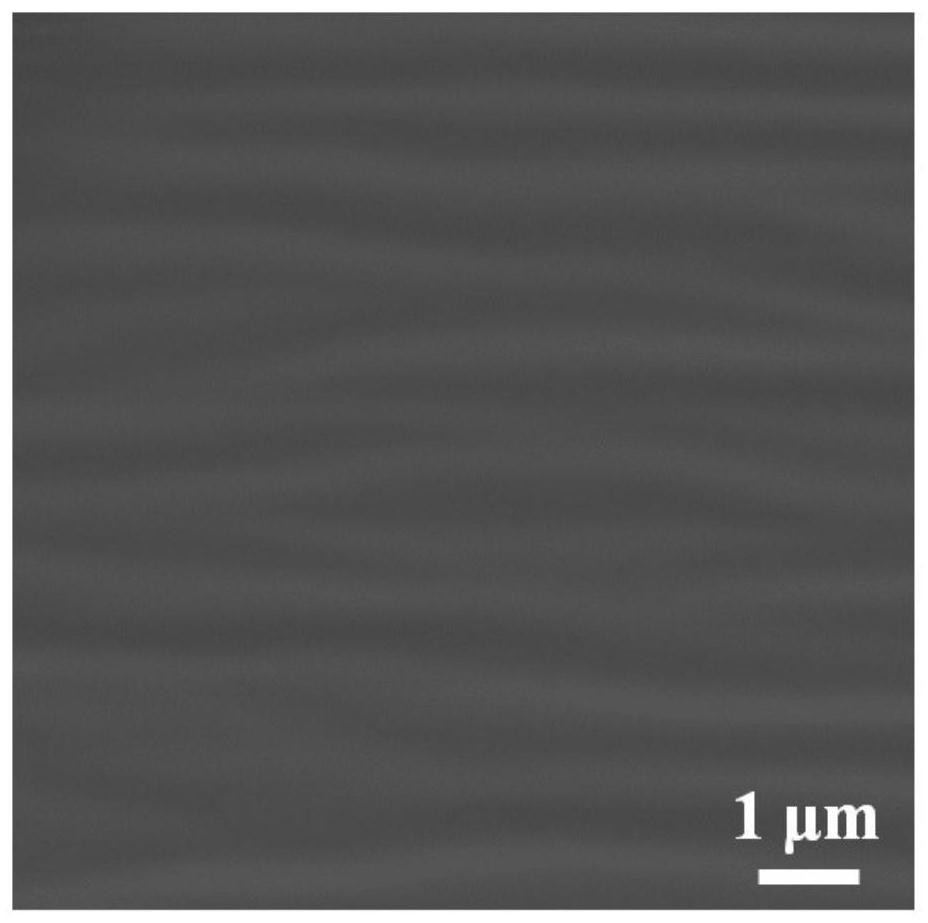

[0086] Weigh 0.8g of Pebax particles into 20mL ethanol solvent, heat to 50°C and stir to form a uniform and transparent Pebax solution; then, add 0.2g of acetyl tributyl citrate (ATBC) to the Pebax solution, and continue to stir evenly ; Finally, the Pebax / ATBC (20) blend was cast onto a PTFE plate, and after the solvent was volatilized to form a film, it was placed in a vacuum oven and dried at 30°C for 1 day; the dried Pebax / ATBC (20) film was placed on the into the desiccator, and finally test the gas separation performance of the membrane material, and the test results are shown in Table 5.

[0087] image 3 SEM image of the section of the Pebax / ATBC(20) blend film: due to the increase in the flexibility of the polymer chain due to the addition of ATBC, the section of the Pebax / ATBC(20) blend film has a corrugated structure. Figure 4 is the thermogravimetric graph of ATBC; Figure 5 It is the thermogravimetric curve of Pebax / ATBC(20) blend film: the mass loss of the fir...

Embodiment 2

[0091] Weigh 0.5g of Pebax particles into 20mL ethanol solvent, heat to 50°C and stir to form a uniform and transparent Pebax solution; then, add 0.5g of acetyl tributyl citrate (ATBC) to the Pebax solution, and continue to stir evenly; finally The Pebax / ATBC(50) blend was cast onto a PTFE plate, and after the solvent evaporated to form a film, it was dried in a vacuum oven for 1 day; the dried Pebax / ATBC(50) blend film was placed in a desiccator Finally, the gas separation performance of the membrane material was tested, and the test results are shown in Table 6. Figure 6 It is the thermogravimetric curve of the Pebax / ATBC(50) blend film: the thermal stability test shows that the mass loss of the first stage of the blend film is ATBC; the initial mass temperature of ATBC in the blend film is above 200°C, The onset temperature of mass loss is higher than that of pure ATBC, indicating that Pebax and ATBC in the blend film have good compatibility and high thermal stability.

...

Embodiment 3

[0095] Weigh 1.6g of TPU particles and add them to 40mL tetrahydrofuran solvent, heat to 40°C and stir to form a uniform and transparent polyurethane solution; then, add 0.4g triethyl citrate (TEC) to the polyurethane solution and continue to stir evenly; The mixed solution was cast onto a PTFE plate, and after the solvent evaporated to form a film, it was placed in a vacuum drying oven at 30°C and dried for 1 day; the dried TPU / TEC (20) film was placed in a desiccator, and finally the film material was tested. Gas separation performance, the test results are shown in Table 7. Figure 7 is the thermogravimetric curve of TEC; Figure 8 It is the thermogravimetric curve of TPU / TEC (20) blend film: the mass loss of the first stage of the blend film is TEC; the initial mass temperature of TEC in the blend film is above 170°C, which is higher than the mass of pure TEC Loss of onset temperature, TPU and TEC in the blend film have good compatibility and good thermal stability.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com