Production method and device capable of automatically arranging dried meat slices

A technology for a production method and a production device, which is applied in the field of meat jerky production method and device for automatic feeding, can solve the problems of low degree of automation, low efficiency, large labor force, etc., and achieve the effect of improving production efficiency and reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

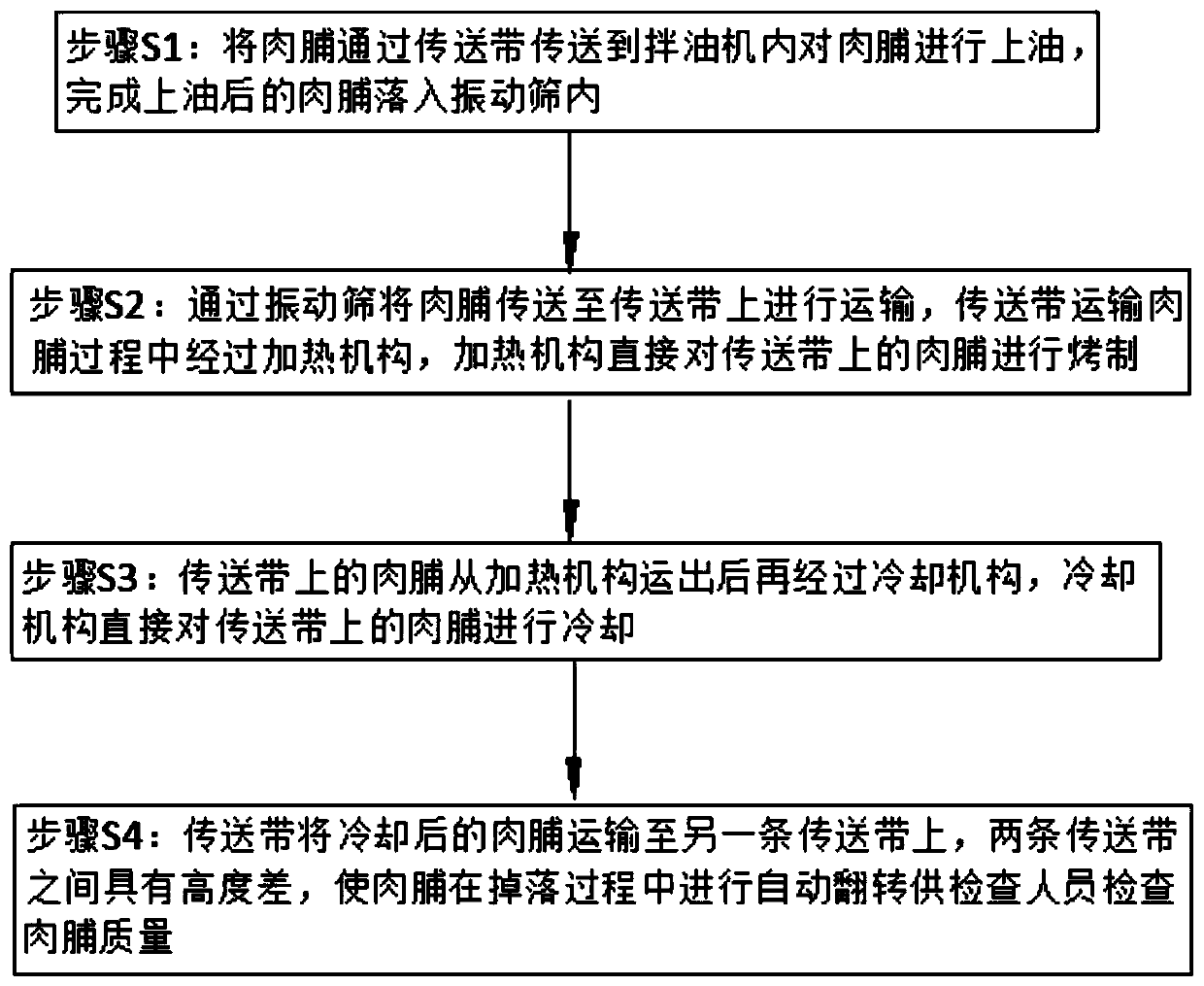

[0034] refer to figure 1 Shown, a kind of dried meat production method of automatic material arrangement comprises:

[0035] Step S1: Screen the jerky, screen out the unshaped minced jerky, place the shaped jerky on the conveyor belt, and transfer the jerky to the drum-type oil mixer 1 through the conveyor belt, and the drum-type oil mixer 1 Adding an appropriate amount of cooking oil in it makes the surface of the jerky evenly oiled when the jerky is turned in the drum type oil mixer 1, which can increase the oil content of the jerky and improve the taste of the jerky, and at the same time prevent the jerky from being transported on the conveyor belt. Sticking to the conveyor belt improves the quality of the finished meat jerky.

[0036] There is a vibrating screen 2 at the outlet of the drum type oil mixer 1, and the dried meat after oiling is transported out of the drum type oil mixer 1 and falls into the vibrating screen 2, and the outlet of the vibrating screen 2 is conn...

Embodiment 2

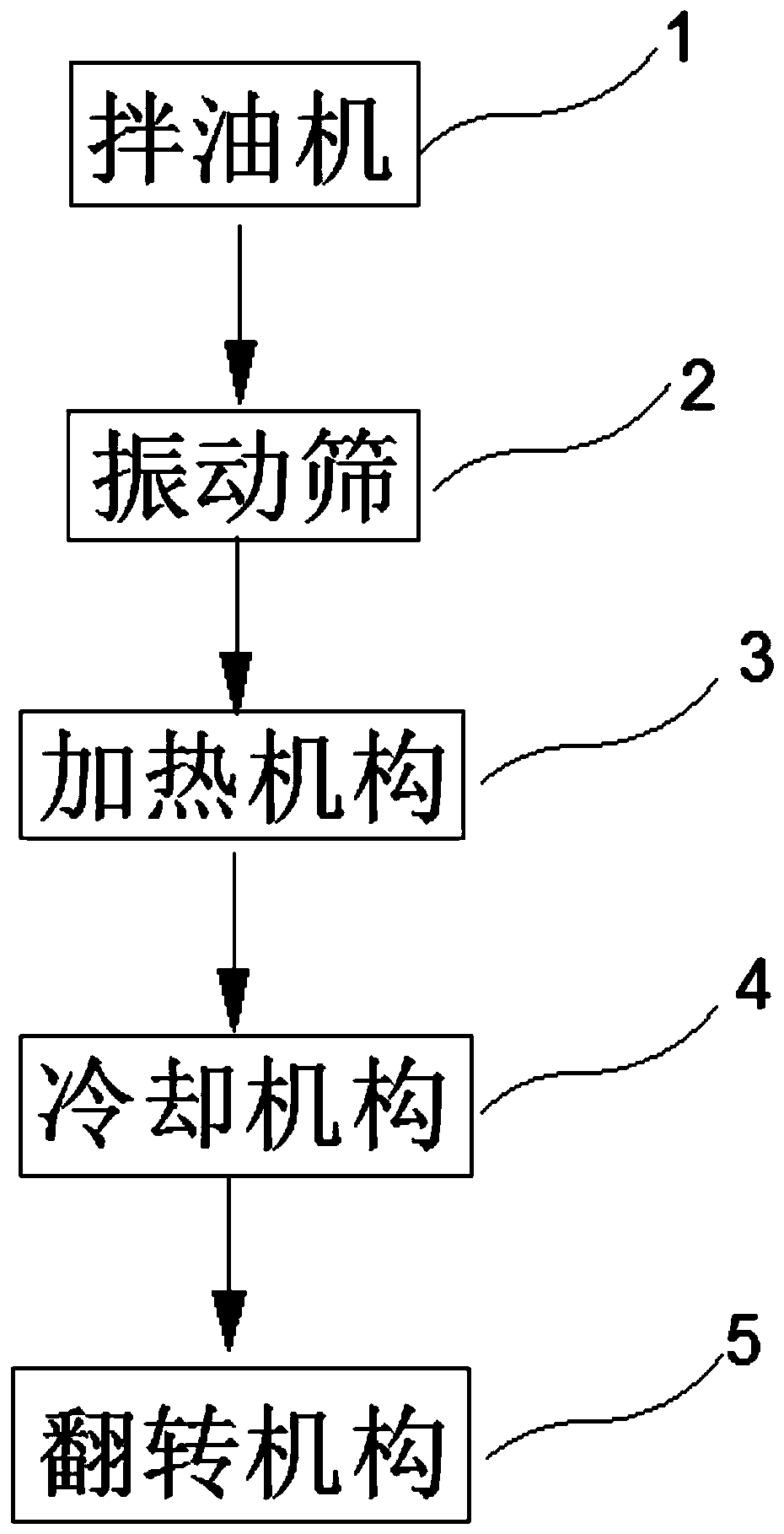

[0048] This embodiment provides a dried meat production device for automatic material handling, which implements the dried meat production method in Embodiment 1, referring to figure 2 As shown, the production facility includes:

[0049] An oil mixer 1, the feed port of the oil mixer 1 is connected to a conveyor belt, and the preserved meat is transported into the oil mixer 1 through the conveyor belt for oiling treatment.

[0050] The vibrating sieve 2 is located directly below the discharge port of the oil mixer 1, and the discharge port of the vibrating screen 2 is connected with the heating mechanism 3 through a conveyor belt. Through the vibration of the vibrating screen 2, the meat jerky is transferred to the conveyor belt in an orderly manner, and the stacked meat jerky is flattened into a layer through the brush mechanism, and the brush mechanism is installed on the discharge port of the vibrating screen 2. On the conveyor belt, there is a preset gap between the brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com