Handle processing device

A processing device and handle technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of high labor production costs, and achieve the effect of avoiding manual transfer and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

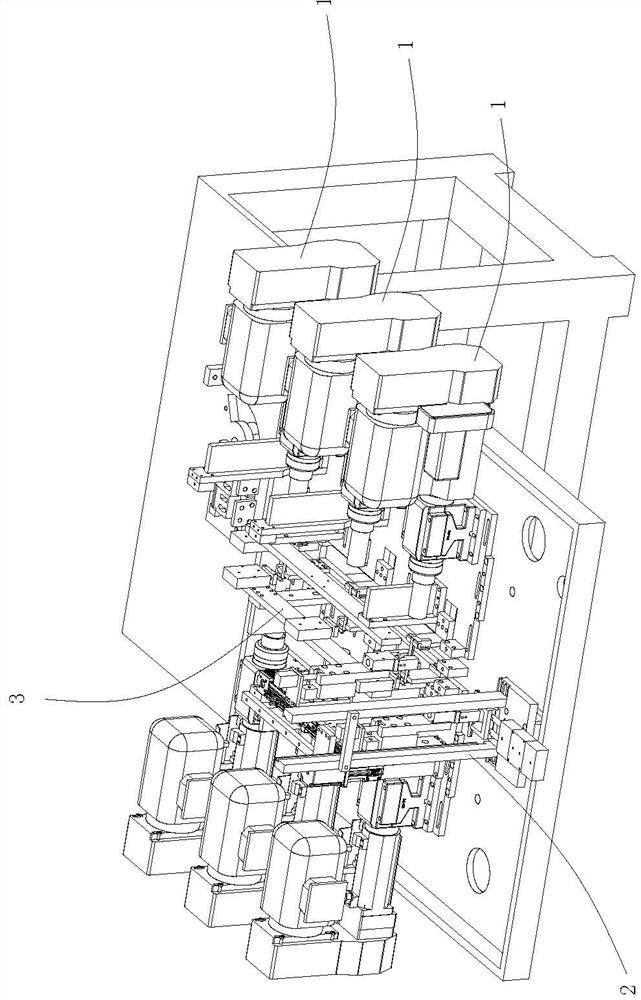

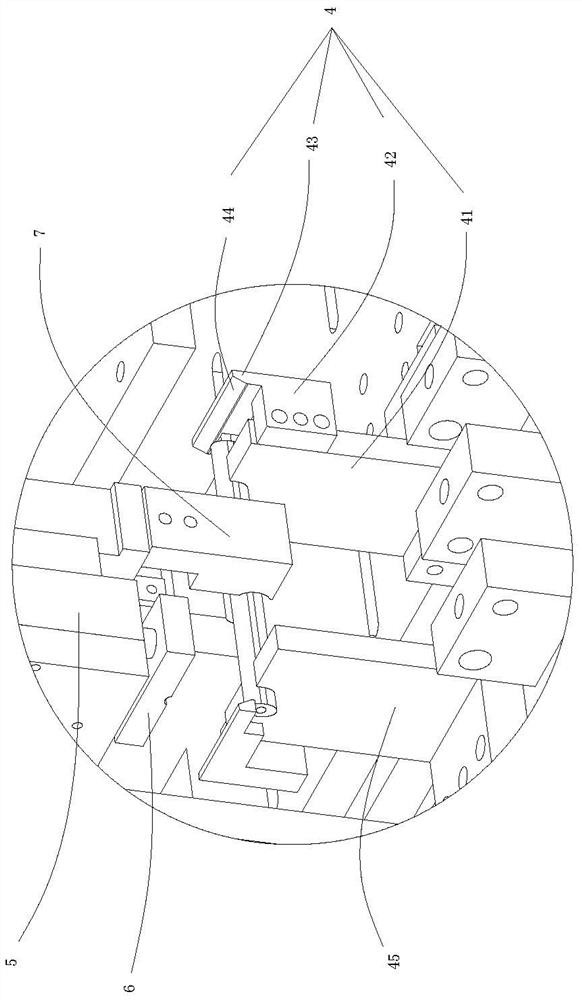

[0028] Embodiment: a handle processing device, which includes: a plurality of processing mechanisms 1, and the processing mechanism 1 is provided with a material processing positioning structure 4;

[0029] Also includes:

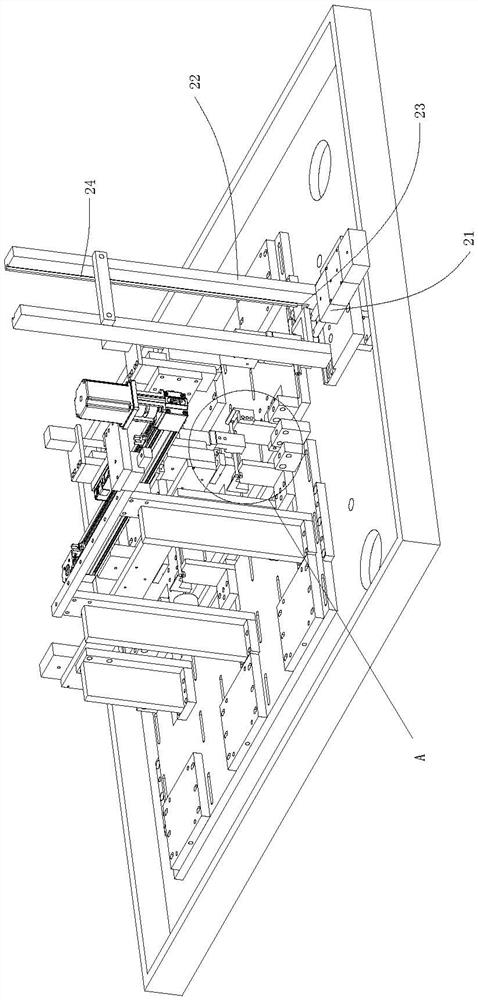

[0030] Material storage mechanism 2, the material storage mechanism 2 is connected with a transfer mechanism for transferring materials to the feeding position;

[0031] The material conveying mechanism 3 is used to sequentially transfer the material from the feeding position to each material processing positioning structure 4 .

[0032] When the technical solution is working, the material is first placed in the material storage mechanism 2, and during processing, one of the materials is transferred to the feeding position through the material transfer mechanism, and then the material conveying mechanism 3 takes the material from the feeding position and transfers it to the feeding position. Transfer to each material processing positioning structure 4 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com