Self walking soil processing machine

A soil treatment, self-propelled technology, applied in soil protection, earth mover/excavator, mixer, etc., can solve the problem of low mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

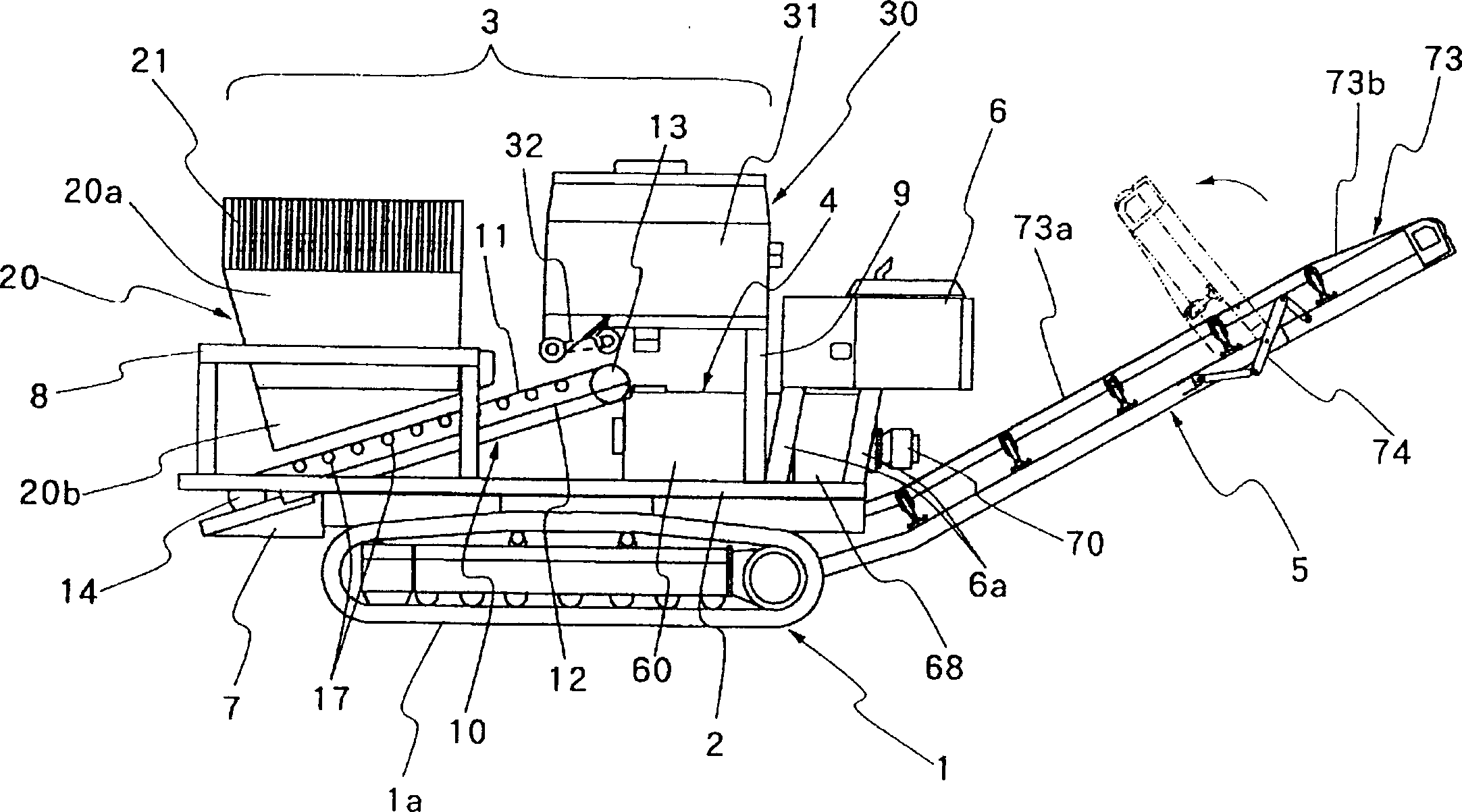

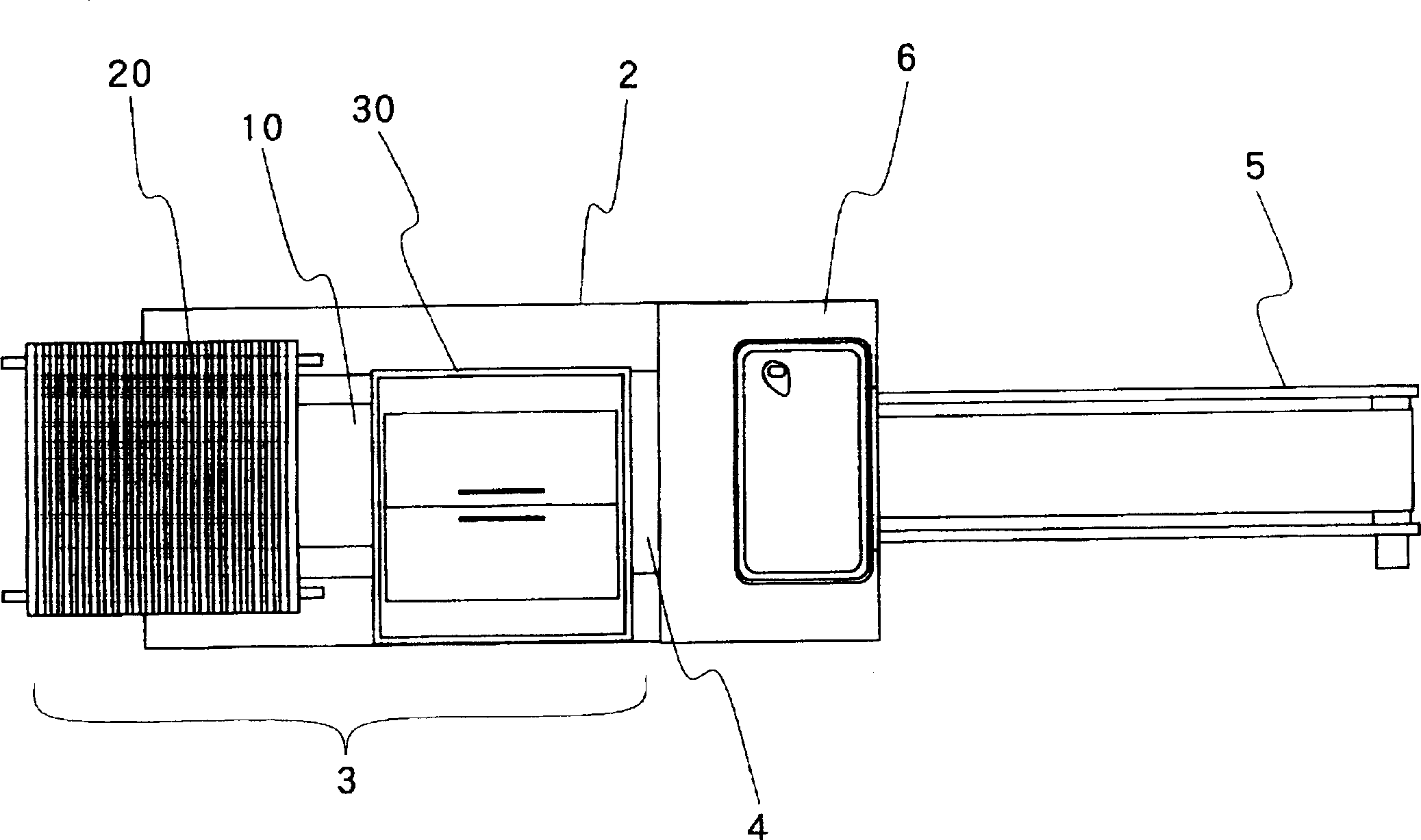

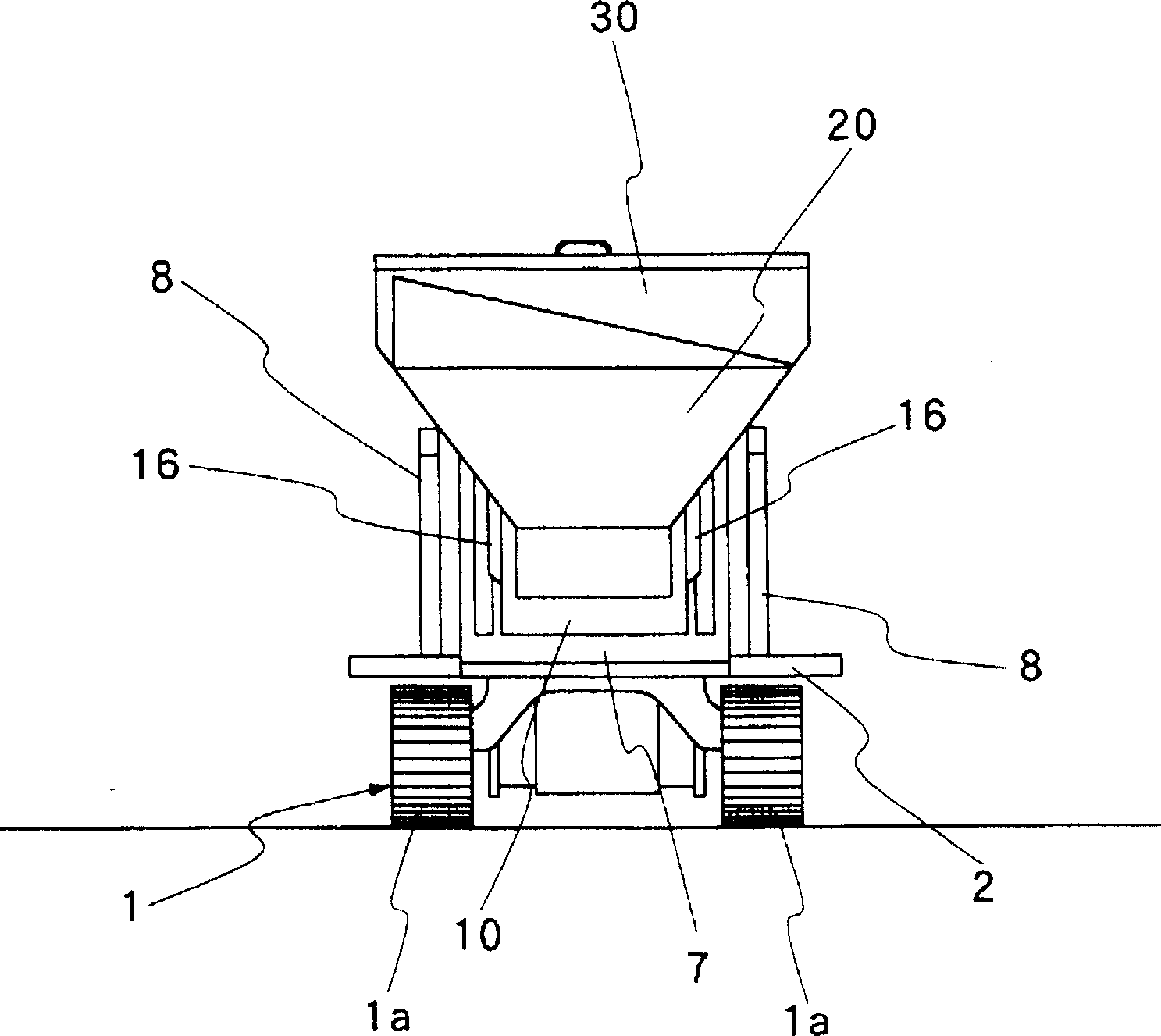

[0054] The present invention will be described in detail below based on preferred embodiments shown in the drawings. Figure 1 to Figure 3 Shown is the vehicle-mounted or self-propelled soil treatment machine of the present invention. figure 1 Here, 1 denotes the basic carrier of the machine, which is a crawler-type vehicle with a crawler 1a, which is well known in the prior art. Since the foundation carrier 1 is a crawler type, when the excavated soil is thrown into the machine, it is possible to prevent the overall machine from becoming unstable due to, for example, loading shock. However, in the case where it is arranged to continuously load the excavated soil with a conveyor or the like, the base carrier may also be a wheeled vehicle.

[0055]A soil feed section 3 and a soil treatment section 4 are installed on the main frame 2 of the foundation carrier 1, and the soil feed section 3 is located at the front of it. figure 1 The soil treatment section 4 is located after the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com