Display panel and preparation method thereof

A display panel and plate technology, applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, electrical components, etc., can solve the problems of thin film transistor device functions that cannot be achieved, active layer film thickness, contact resistance damage, source, Problems such as the inability of the drain and the active layer to conduct, achieve the effects of mass production, improved conduction characteristics, and increased edge contact paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative efforts fall within the protection scope of the present invention.

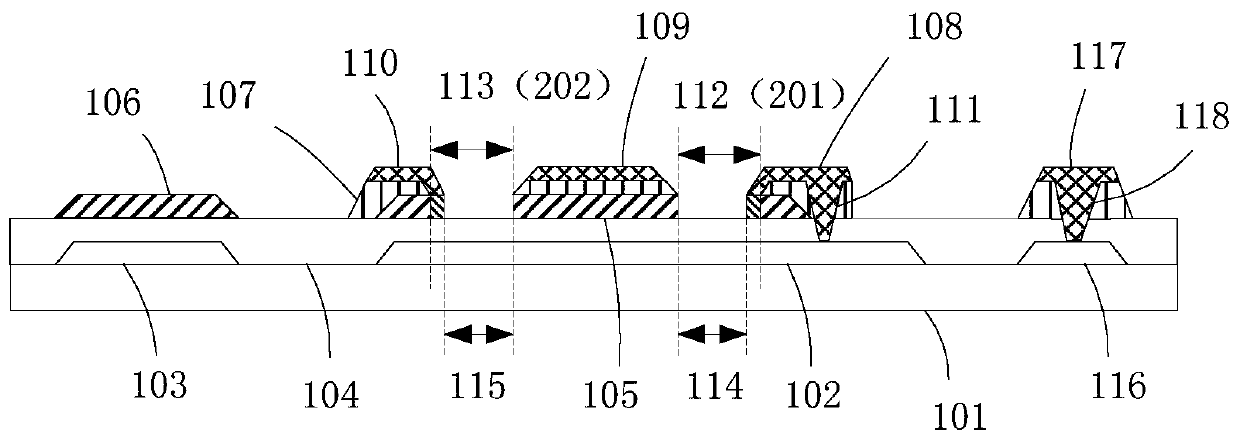

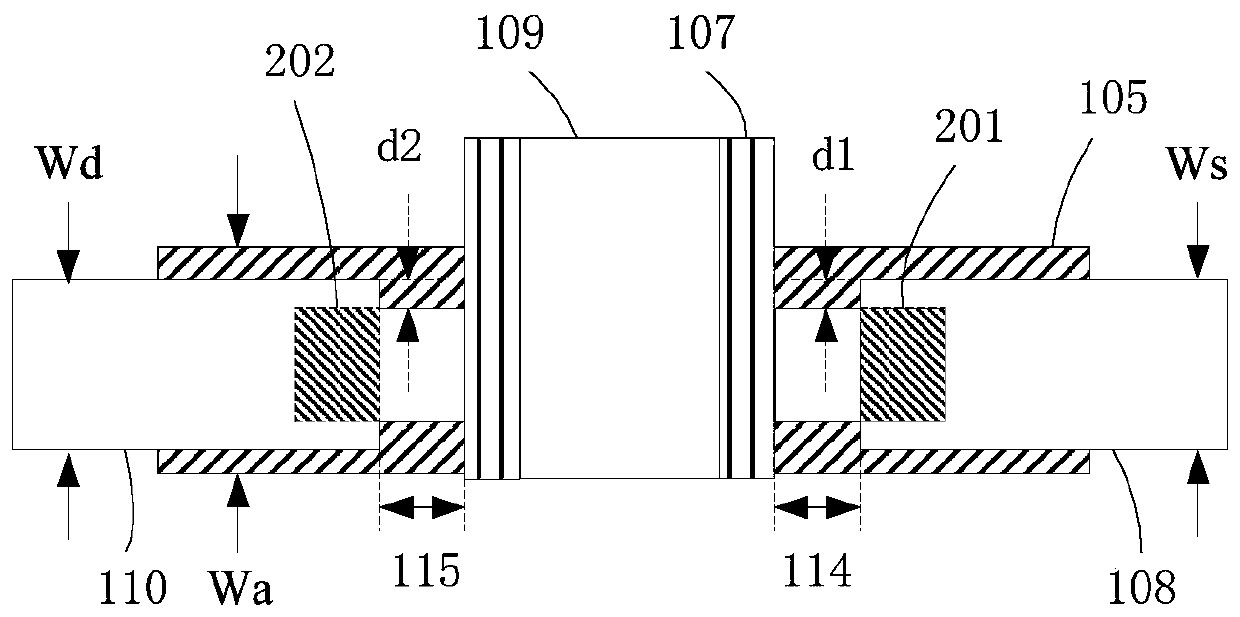

[0023] see figure 1 , the schematic diagram of the basic structure of the display panel provided by Embodiment 1 of the present invention. From the figure, it is possible to intuitively see the various components of the present invention and the relative positional relationship between the various components. The display panel includes a substrate layer 101 , the light-shielding metal layer 102 on the substrate layer 101 and the first plate 103 of the storage capacitor, the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com