Fabric drying device for textile industry

A technology for fabric drying and textile industry, applied in drying, dryer, drying gas arrangement and other directions, can solve problems such as inability to guarantee fabric and heat source, uneven heating of fabric, affecting drying effect, etc., to achieve flexible use , The effect of heating evenly and prolonging the moving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

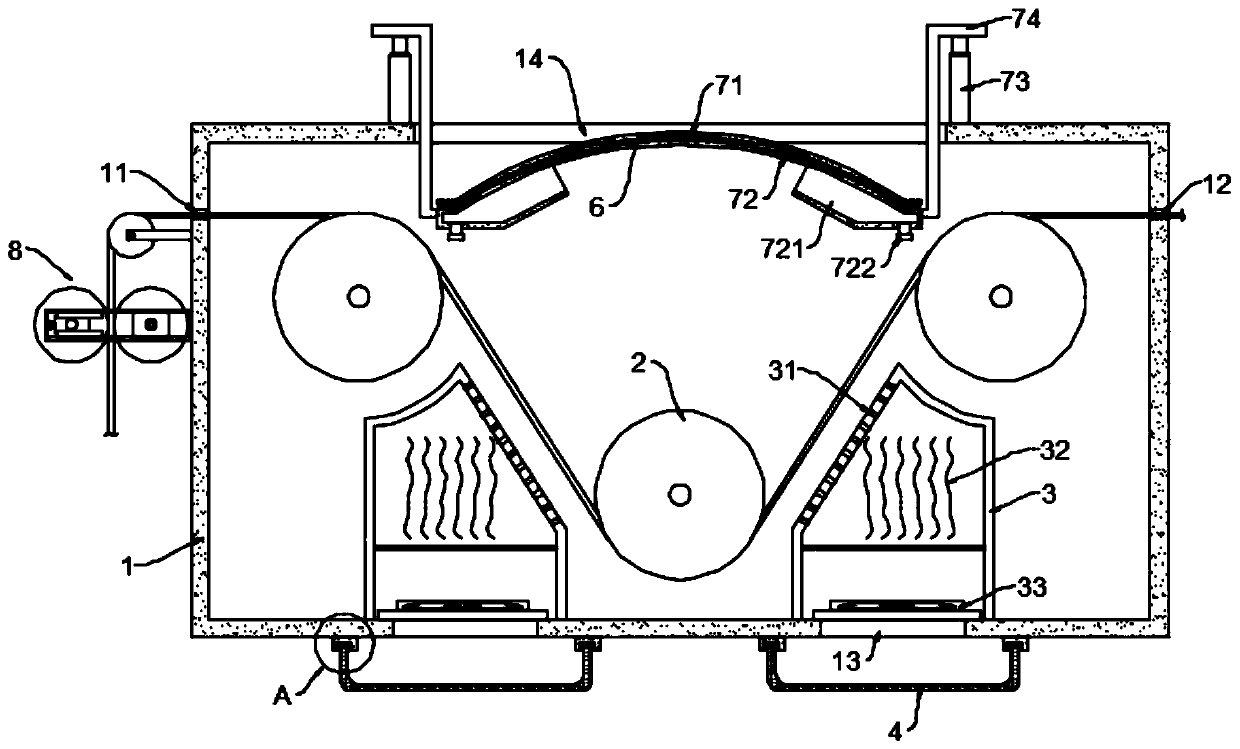

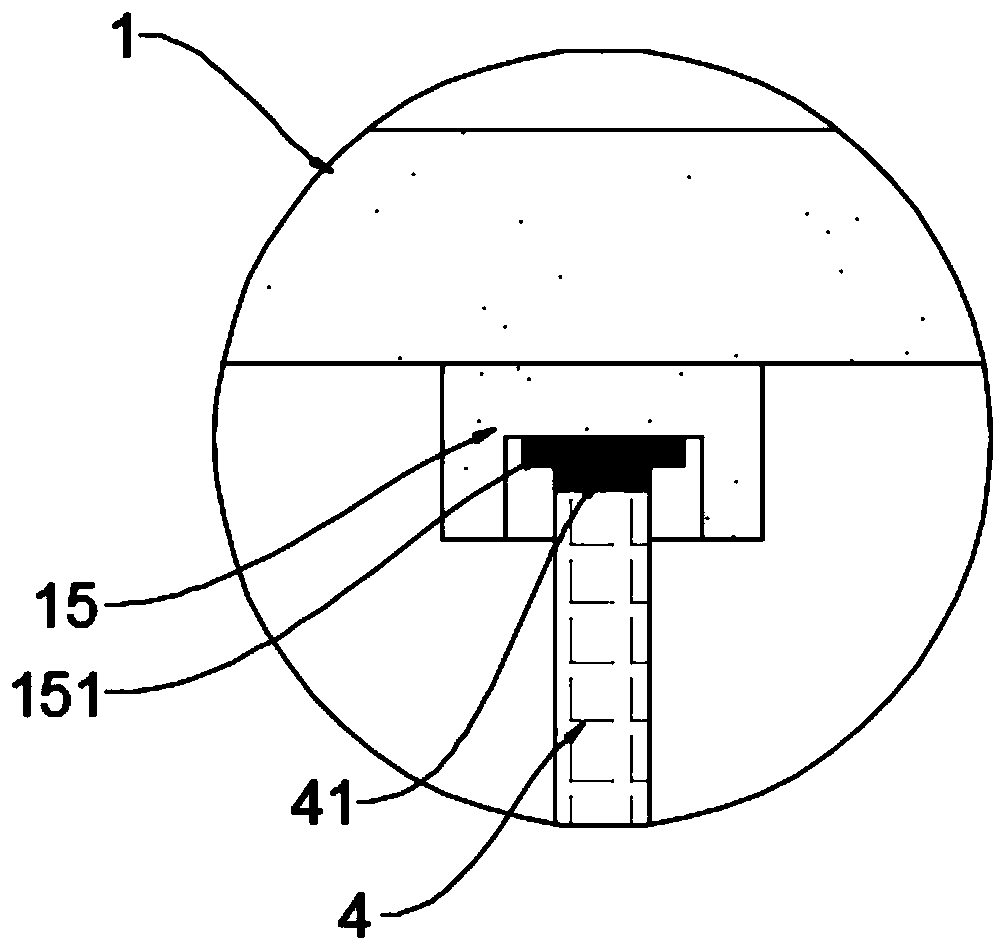

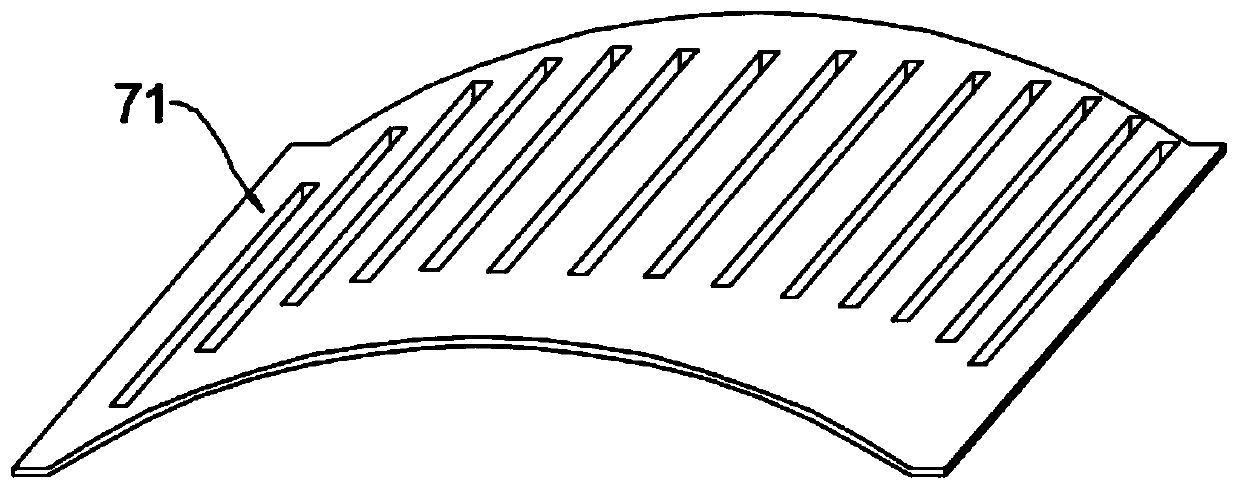

[0023] see Figure 1~3 , in an embodiment of the present invention, a fabric drying device for the textile industry, comprising a box body 1 and a drying mechanism arranged in the box body 1; the box body 1 is provided with conveying rollers 2 arranged in a triangle, and the box body 1 The two side shell walls of the body 1 are symmetrically provided with an inlet 11 and an outlet 12 for the cloth to enter and exit. During the working process, the cloth moves in the box body 1, and the conveying rollers 2 arranged in a triangle enable the cloth to travel along the folding line and extend its length. Movement time in box 1.

[0024] The drying mechanism includes a heat source frame 3 and a fan 33, wherein the heat source frame 3 is fixed on the inner wall of the box body 1 and covers the air inlet 13 provided on the casing wall of the box body 1. The heat source frame 3 An electric heating wire 32 is installed inside, and the heat source frame 3 has an inclined plane parallel ...

Embodiment 2

[0033] see figure 1 and 4 , the difference between the embodiment of the present invention and embodiment 1 is:

[0034] In this embodiment, an extruding mechanism 8 is also included. The extruding mechanism 8 is arranged on the outer wall of the box body 1 at a position corresponding to the inlet 11. The extruding mechanism 8 includes an installation frame 81 and is arranged symmetrically in the installation frame 81. The arranged extrusion roller squeezes the cloth by the extrusion roller, thereby extruding the moisture on the cloth, so that the cloth can be dried faster after entering the box body 1 .

[0035]Further, the squeeze roller includes a movable roller 82 and a fixed roller 83, wherein the movable roller 82 is mounted on a movable seat 85 slidably connected to the mounting frame 81, and the fixed roller 83 is mounted on a fixed seat fixed to the mounting frame 81 84, a telescopic device 86 is also installed on the inner frame surface of the installation frame 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com