Heat absorption tower drum external suspension type molten salt pipeline system and molten salt pipeline suspension method

A pipeline system and heat-absorbing tower technology, applied in the field of tower-type photothermal power generation, can solve the problems of large space in the tower, increased pipeline cost, and increased cost of heat-absorbing towers, and achieve simple construction and hoisting machinery, reasonable use of material strength, The effect of reducing the single lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

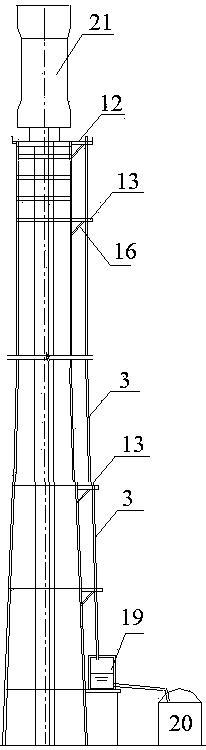

[0049] This embodiment provides a molten salt pipeline system suspended outside the heat absorbing tower tube, such as figure 1 As shown, it includes a molten salt pipeline 3, a tower top suspension support structure 12, a tower body limit support structure 13, a pipeline suspension point connection member 24 and a pipeline limit point connection member 25, and the tower body limit support structure 13 is provided with Multiple, the tower top suspension support structure 12 and the tower body limit support structure 13 are partially cantilevered out of the tower, and the tower top suspension support structure 12 is provided with a suspension support steel beam 14 on the cantilevered part. The limit support structure 13 cantilevered part of the tower body is provided with a limit support steel beam 15;

[0050] The molten salt pipeline 3 is provided with a pipeline connector 11, the upper part of the molten salt pipeline 3 is connected to the pipeline suspension point connecti...

Embodiment 2

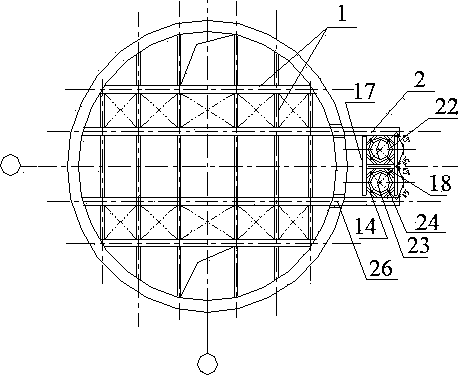

[0053] On the basis of Embodiment 1, this embodiment provides a molten salt pipeline system suspended outside the heat absorbing tower, such as figure 2 As shown, the tower top suspension support structure 12 is a horizontal and vertical steel truss 1, and the horizontal and vertical steel truss 1 includes an upper chord steel beam, a lower chord steel beam and a middle web, and the two ends of the upper chord steel beam and the lower chord steel beam Both are rigidly connected to the concrete corbels on the inner side of the tower wall, and the upper chord steel beam and the lower chord steel beam are connected through the middle web;

[0054] The cantilevered part of the tower top suspension support structure 12 is selected from the outer side of the tower wall by the upper chord steel beam to form a suspension point platform steel beam 2, and the lower flange of the suspension point platform steel beam 2 is connected with a 45 ° oblique support 16, so The other end of the ...

Embodiment 3

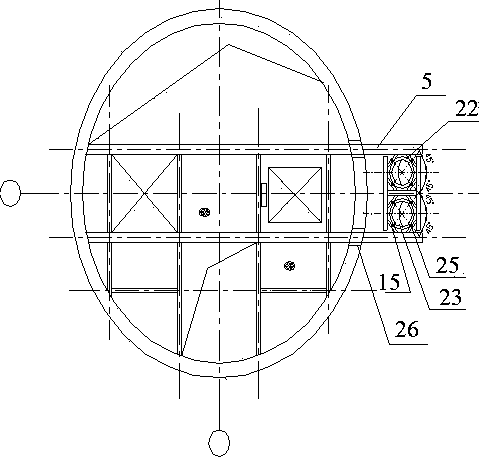

[0059] On the basis of Embodiment 1, this embodiment provides a molten salt pipeline system suspended outside the heat absorbing tower, such as image 3 As shown, the cantilevered part of the tower body limit support structure 13 is in the same form as the cantilevered part of the tower top suspension support structure 12, and the upper chord steel beam picks out the outer side of the tower wall to form a limit point platform steel beam 5, and a 45° oblique 16 towards the support.

[0060] Set up limit point platform steel beams 5 at every 20-30m along the tower body. In order to meet the convenience of workers' inspection and maintenance, a steel platform inside the tower should be set at this elevation for use by elevators and stairwells.

[0061] The main feature of the tower body limit support structure 13 is that it does not support the gravity and internal pressure of the molten salt pipeline 3, but only limits the horizontal swing caused by wind load or other factors. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com