Impact rotary jet grouting drilling tool

A drilling tool and nozzle technology, which is applied in the direction of liquid/gas jet drilling, drill bits, drill pipes, etc., can solve the problems of long construction hours, low construction costs, cumbersome construction procedures, etc., and achieve saving installation space and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

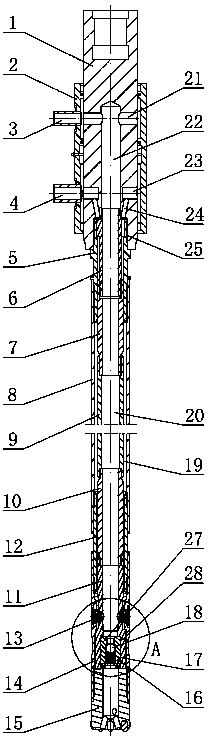

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 , figure 2 As shown, the present invention is a shaft assembly, a drill pipe assembly, and a nozzle bit assembly from top to bottom. The upper end of the drill pipe assembly is connected to the shaft assembly through a joint assembly, and the lower end of the drill pipe assembly is connected to the nozzle drill assembly through a joint assembly.

[0031] Such as figure 1 , figure 2 As shown, the outer periphery of the main shaft 1 of the rotating shaft assembly is provided with a casing 2, and the outer periphery of the casing 2 is embedded with a water inlet 3 and an air inlet 4 along the radial direction, and the water inlet 3 and the air inlet 4 are located on the same side of the same longitudinal section , the central axes of the two are parallel to each other, and the water inlet 3 and the air inlet 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com