Terrace steel formwork erection adjuster and manufacturing method thereof

A steel formwork and adjuster technology, which is applied in the direction of building construction, construction, and building material processing, to achieve the effects of weak work type, simple axis control, and reduced demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

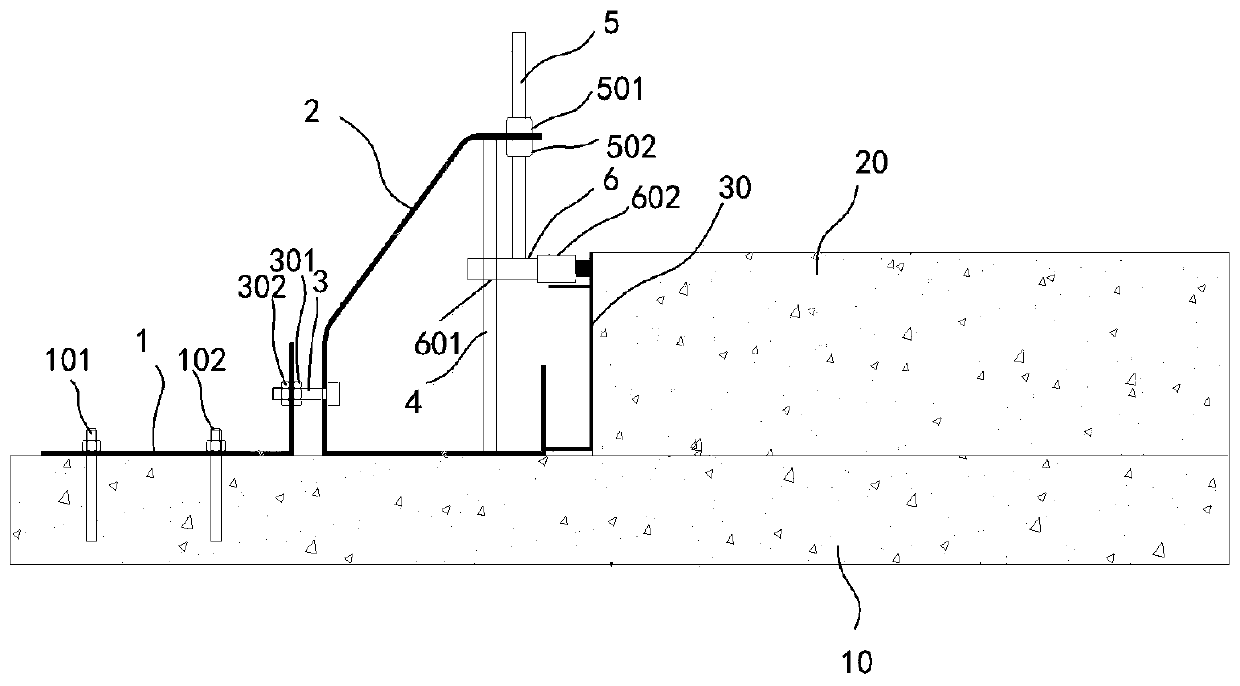

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

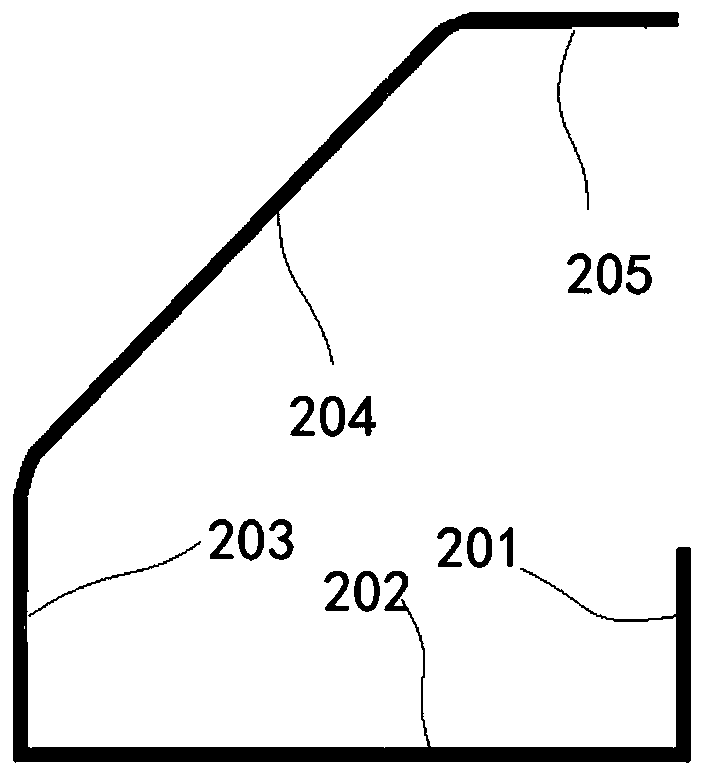

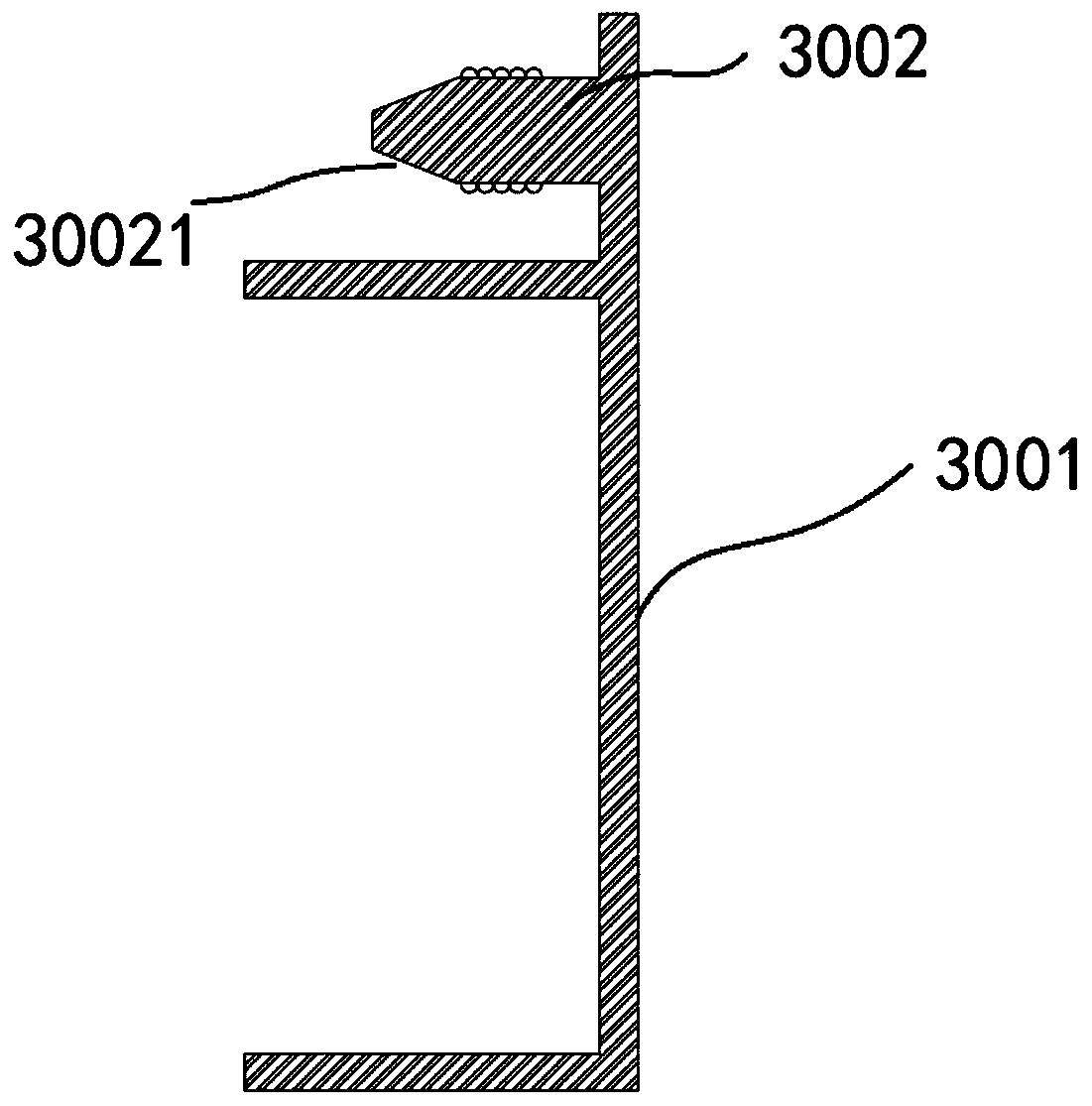

[0038] In the specific preparation process of concrete, a layer of concrete cushion 10 is poured first, and then floor concrete 20 is poured on the concrete cushion 10, forming a ladder between the concrete cushion 10 and floor concrete 20, and the steel The mold 30 needs to be installed on the side of the floor concrete 20 to fix the floor concrete 20. In practice, a special steel mold 30 should be used together, which is the instruction manual image 3 Steel mold shown.

[0039] This device is applied to steel mold adjustment after concrete pouring, such as Figure 1-Figure 4 As shown, one end of the device is installed inside the concrete cushion 10, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com