A kind of sea wormwood polysaccharide with anti-oxidation and regulating intestinal flora effect and its preparation method and application

A technology for regulating intestinal flora and Artemisia japonica polysaccharide, applied in the field of polysaccharides, can solve the problems of high energy consumption, high reaction temperature, long reaction time, etc., and achieves high degradation efficiency, mild reaction conditions, and simple and easy-to-operate equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]1) After drying the Artemisia annua, crush it, pass through a 60-mesh sieve, mix the Artemisia Artemisiae powder with 95% ethanol at a mass volume ratio of 1g:3mL, add 95% ethanol, heat and reflux for 3 hours at a temperature of 70°C, and centrifuge After 20 minutes, the residue was separated, and the residue was repeated twice, and dried at 45°C for 24 hours;

[0039] 2) Mix the dry powder pretreated in step 1) with water at a mass-to-liquid ratio of 1 g: 20 mL, and extract at a temperature of 80° C. for 2 hours and 2 extraction times; centrifugal separation, Combine the extracts, concentrate under reduced pressure at 50°C to 1 / 4 of the original volume, and obtain the concentrated solution of Artemisia annua polysaccharide;

[0040] 3) Add Sevag reagent to the concentrated solution of Artemisia polysaccharides, the volume ratio of the concentrated solution of Artemisia polysaccharides to Sevag reagent (chloroform:n-butanol=3:1) is 4:1, shake for 30min, and centrifuge to...

Embodiment 2

[0045] 1) After drying the sea wormwood, crush it, pass through a 60-mesh sieve, add 95% ethanol according to the mass volume ratio of the sea wormwood powder to 95% ethanol, heat and reflux for 4 hours at a temperature of 70°C, and centrifuge for 20 minutes , the residue was separated, and the residue was repeated twice for the above operation, and dried at 45°C for 24h;

[0046] 2) Mix the dry powder pretreated in step 1) with water at a mass-volume ratio of 1g:20mL, and extract at a temperature of 80°C for 2 hours and 3 extraction times; centrifugal separation, Combine the extracts, concentrate under reduced pressure at 50°C to 1 / 4 of the original volume, and obtain the concentrated solution of Artemisia annua polysaccharide;

[0047] 3) Add Sevag reagent to the concentrated solution of Artemisia polysaccharides, the volume ratio of the concentrated solution of Artemisia polysaccharides to Sevag reagent (chloroform:n-butanol=3:1) is 4:1, shake for 30min, and centrifuge to r...

Embodiment 3

[0052] 1) After drying the sea wormwood, crush it, pass through a 60-mesh sieve, add 95% ethanol according to the mass volume ratio of sea wormwood powder and 95% ethanol, heat and reflux for 3 hours at a temperature of 70°C, and centrifuge for 20 minutes , the residue was separated, and the residue was repeated twice for the above operation, and dried at 50°C for 24 hours;

[0053] 2) Mix the pretreated dry powder in step 1) with water at a mass-volume ratio of 1 g: 20 mL, and extract at a temperature of 80° C. for 2 hours and 4 extraction times; centrifugal separation, Combine the extracts, concentrate under reduced pressure at 50°C to 1 / 10 of the original volume, and obtain the concentrated solution of Artemisia annua polysaccharide;

[0054] 3) Add Sevag reagent to the concentrated solution of Artemisia polysaccharides, the volume ratio of the concentrated solution of Artemisia polysaccharides to Sevag reagent (chloroform:n-butanol=3:1) is 4:1, shake for 30min, and centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

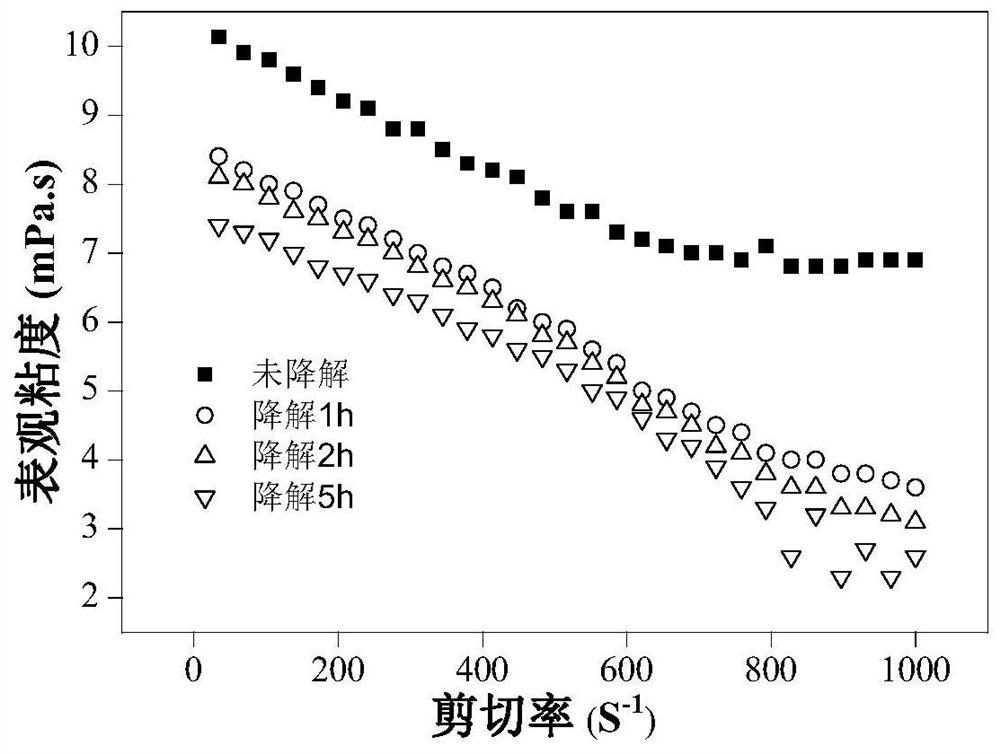

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com