A rotary table type automatic candy twist packaging machine

A packaging machine, turntable technology, used in packaging, packaging sterilization, transportation and packaging, etc., can solve problems such as difficulty in tearing packaging, mechanical corrosion, candy pollution, etc., to improve product hygiene requirements, avoid collision damage, avoid The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

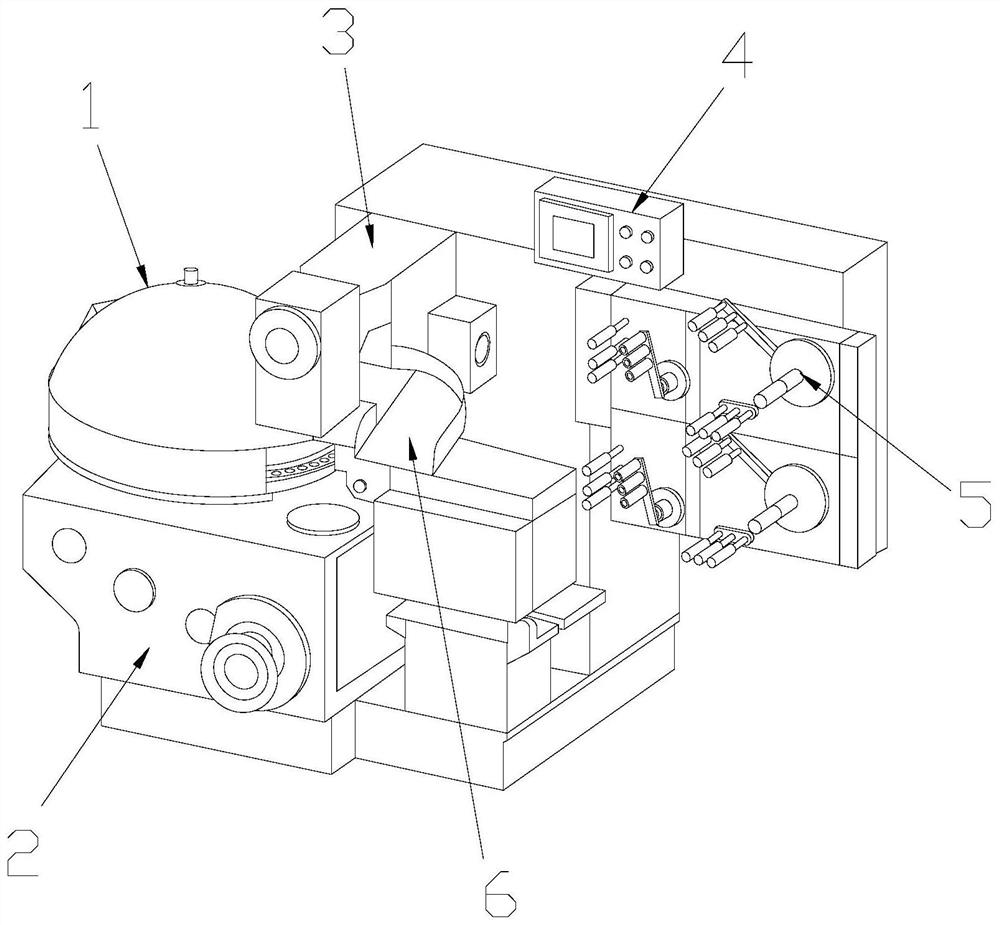

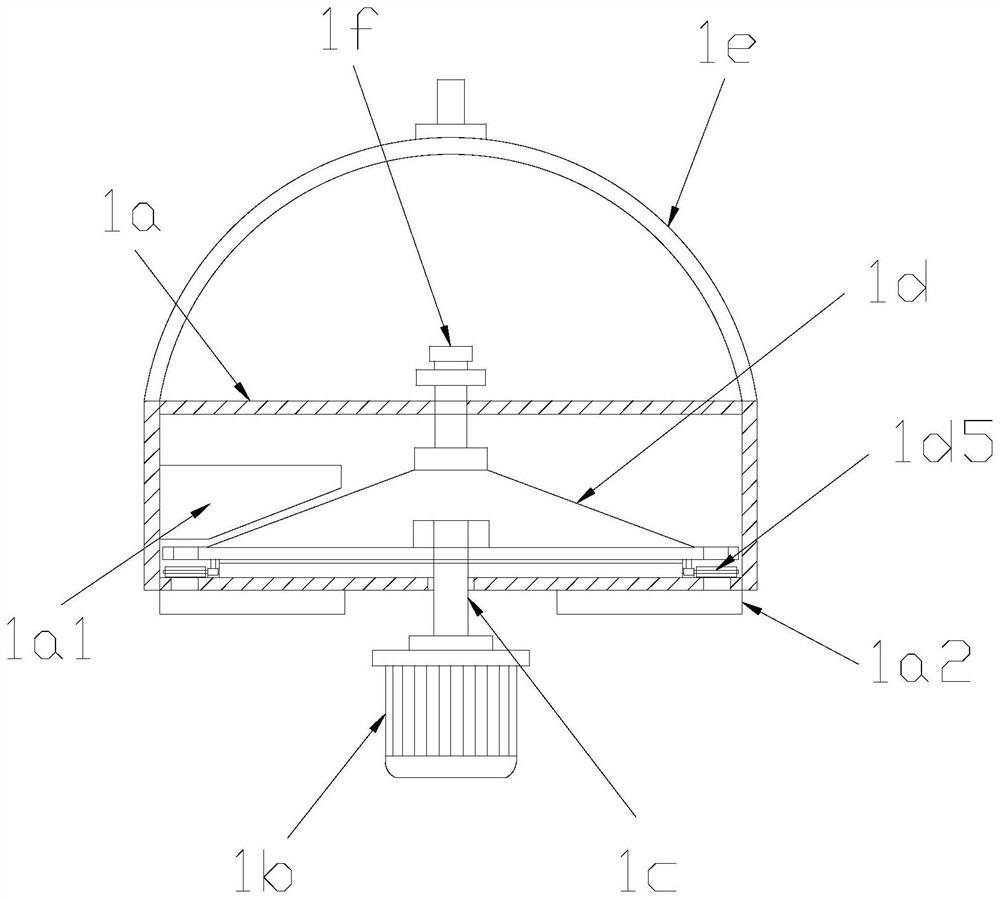

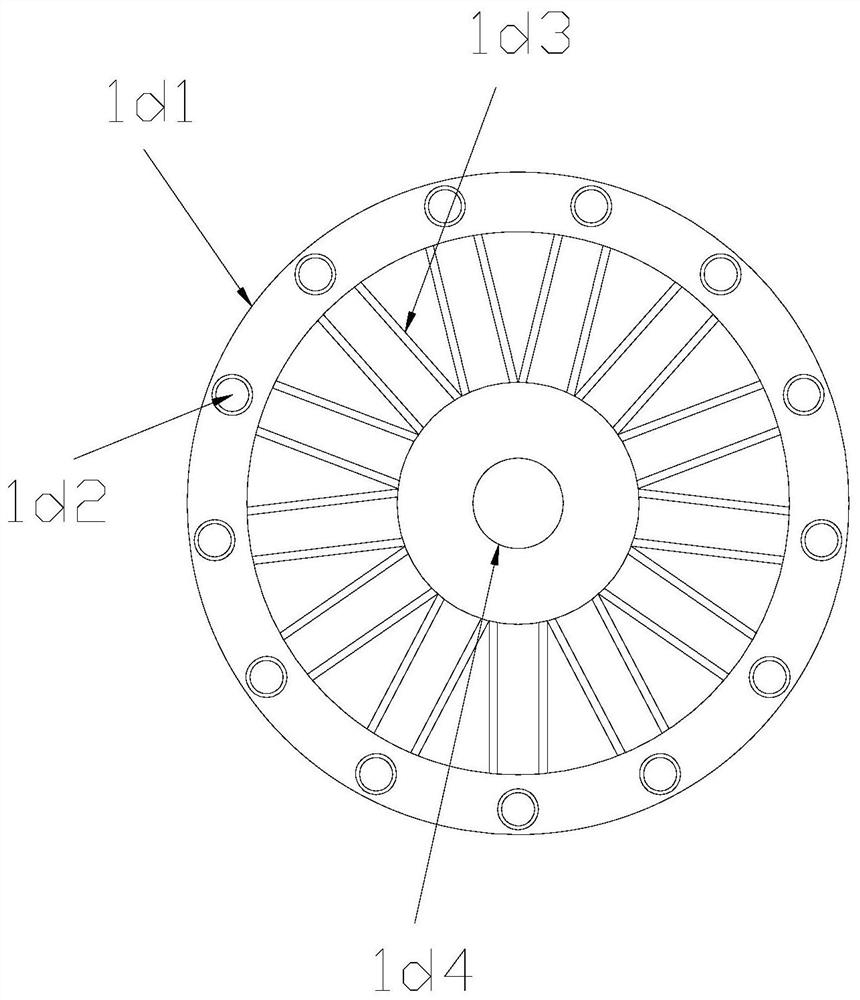

[0029] see Figure 1-Figure 4 , the present invention provides a turntable type automatic candy twist packaging machine, the structure of which includes a sugar sorting device 1, a packaging machine 2, a sugar sealing machine 3, an electric controller 4, an unwinding device 5, and a sugar unloading mechanism 6. The packaging A sugar sorting device 1 is arranged on the right side of the top of the machine 2, and the described packaging machine 2 and the sugar sorting device 1 adopt a clearance fit, and an electric controller 4 is installed on the top of the described packaging machine 2, and the described packaging machine 2 is provided with a There is a sugar sealing machine 3, the packaging machine 2 is connected with the sugar sealing machine 3, the sugar sealing machine 3 is provided with a sugar unloading mechanism 6, and the sugar sealing machine 3 and the sugar unloading mechanism 6 are mechanically connected, The front end of the packaging machine 2 is provided with an ...

Embodiment 2

[0038] see Figure 1-Figure 6 , the present invention provides a turntable type automatic candy twist packaging machine, the dust cover 1e is composed of a cover body 1e1, a handle 1e2, a feeding window 1e3, and a fitting ring 1e4, and the top of the cover body 1e1 is provided with There is a handle 1e2, the cover body 1e1 is glued to the handle 1e2, the surface of the cover body 1e1 is provided with a blanking window 1e3, and the bottom end of the cover body 1e1 is provided with a fitting ring 1e4. The above-mentioned cover body 1e1 is connected with the fitting ring 1e4.

[0039] A power board 1e11 is installed under the inner top of the cover body 1e1, and an ultraviolet disinfection lamp 1e12 is arranged under the power board 1e11, and the power board 1e11 is electrically connected with the ultraviolet disinfection lamp 1e12.

[0040] A buffer blanking plate 1e31 is provided under the inner side of the blanking window 1e3, and the blanking window 1e3 and the buffer blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com