Circulating ball type electric power steering gear

A technology of electric power steering and recirculating ball, which is applied in the direction of electric steering mechanism, power steering mechanism, mechanical steering gear, etc. It can solve the problem of unreasonable setting of the connection mechanism of the mechanical recirculating ball structure of the reducer, the inability to realize unmanned driving and assisted driving, The steering of the system is not light enough and flexible enough to achieve the effect of continuous and smooth hand feeling, strong mechanical characteristics and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

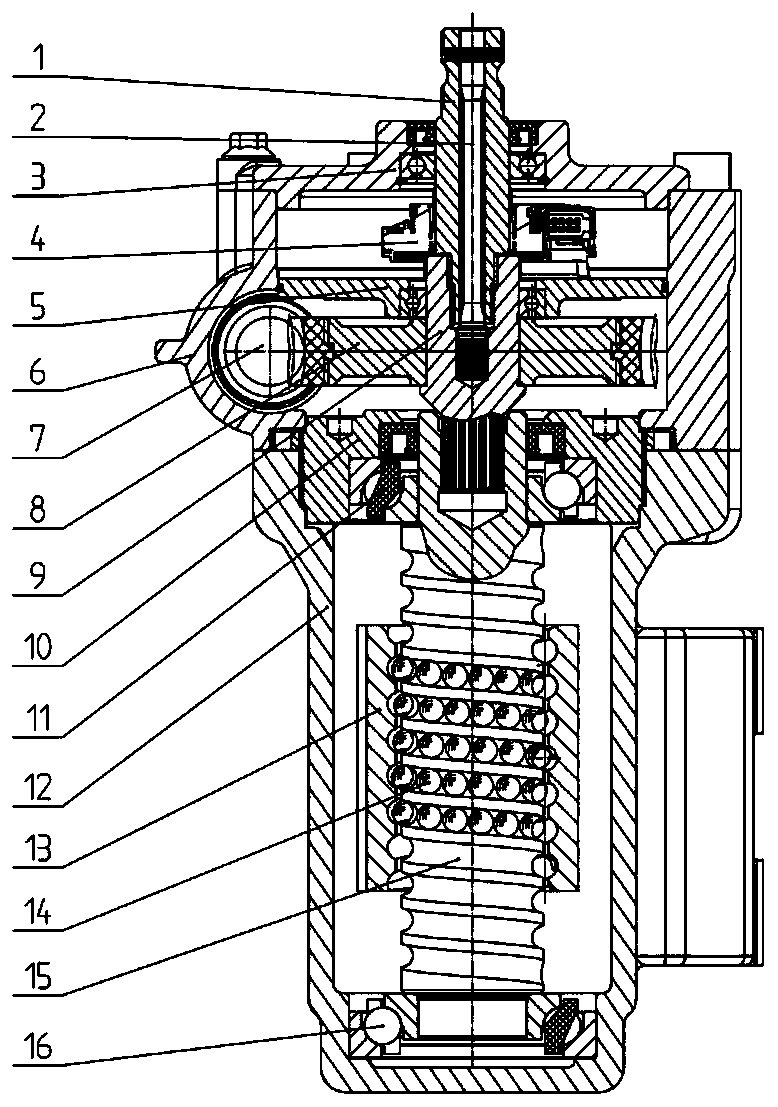

[0053] A recirculating ball type electric power steering, such as figure 1 , figure 2 , image 3 As shown, it includes a mechanical steering gear, a reducer, the integrated motor controller 26, and a sensor; the mechanical steering gear is provided with a steering gear housing 12 and a steering screw 15, and the speed reducer is provided with a speed reducer housing 6. The steering gear housing 12 and the reducer housing 6 are fixed through a detachable connection; the reducer is internally provided with a steering input shaft 1 and a worm gear shaft 9, and the steering input shaft 1 and the worm gear shaft 9 They are flexibly connected by an elastic torsion bar 2; sensors are installed at the connection between the input end of the steering input shaft 1 and the output end of the worm gear shaft 9 .

[0054] The sensor is a Hella torque sensor 4 .

[0055] The output torque signal of the Hella torque sensor 4 is PWM, the duty cycle is 12.5%-87.5%, and the rotation angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com