Paperboard indentation device for packaging box production

A packaging box and cardboard technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of inconvenient transportation of cardboard, affecting equipment life, and impact on indentation quality, so as to improve indentation efficiency and reliability. The effect of ensuring accuracy and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

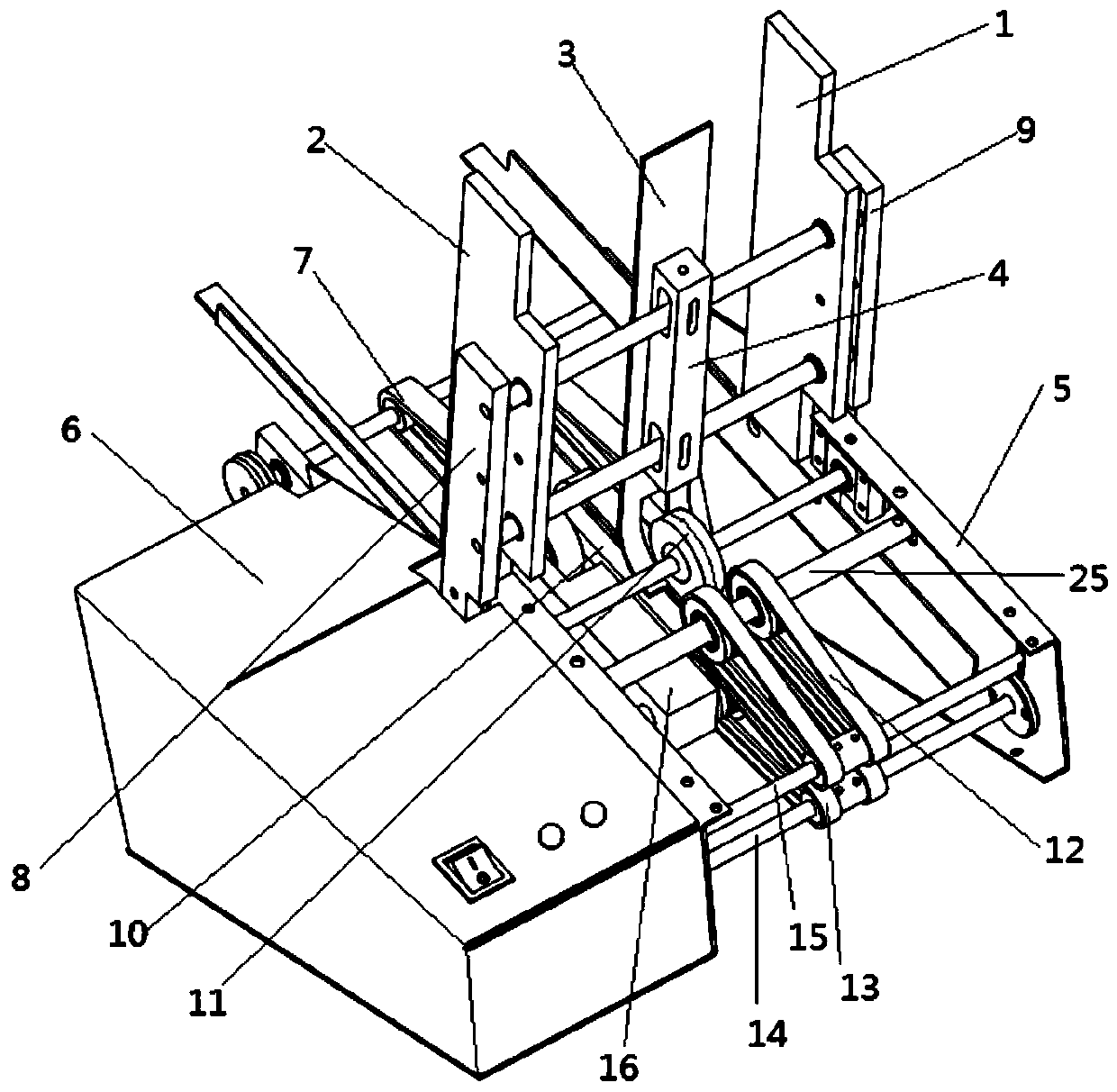

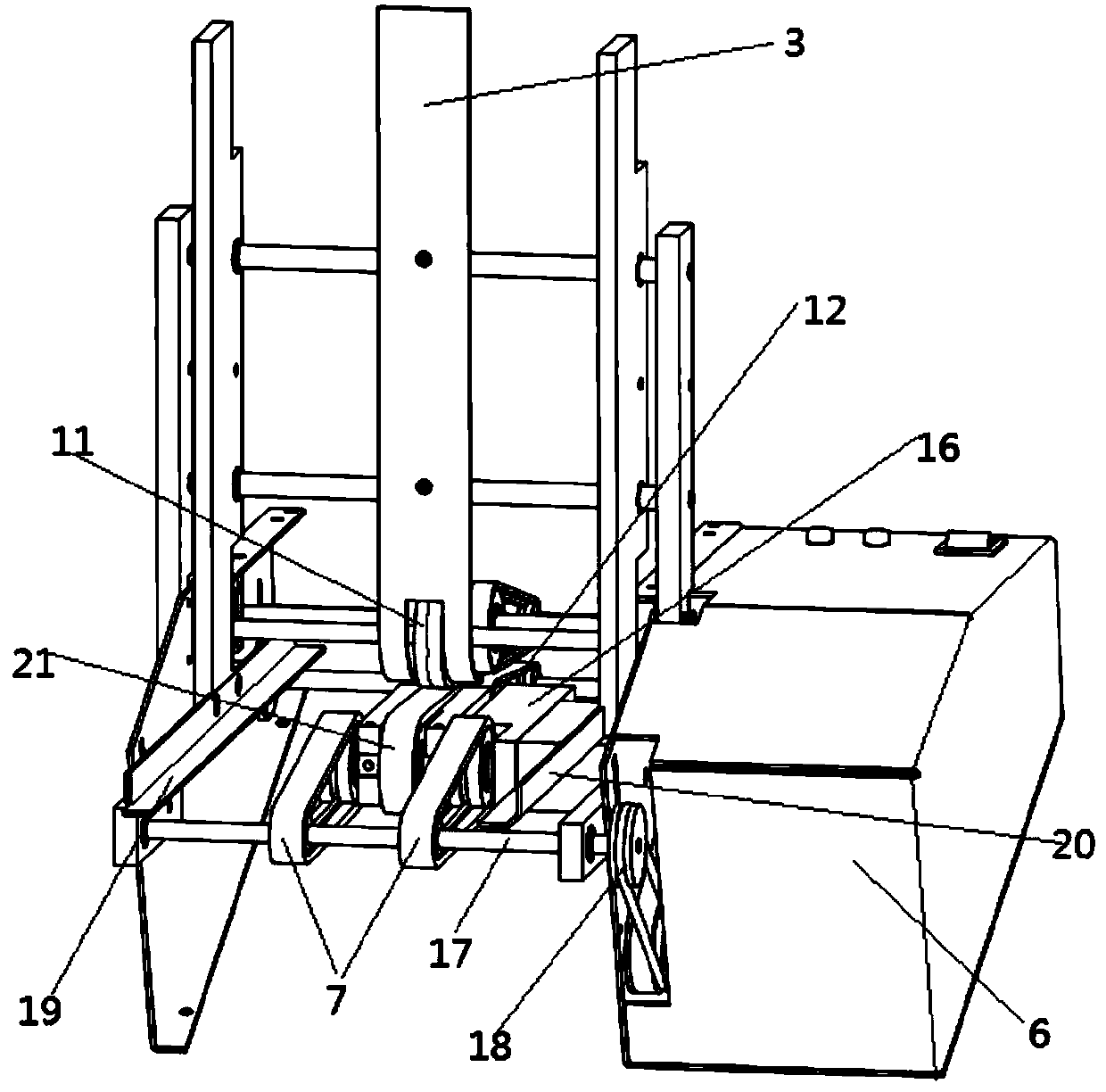

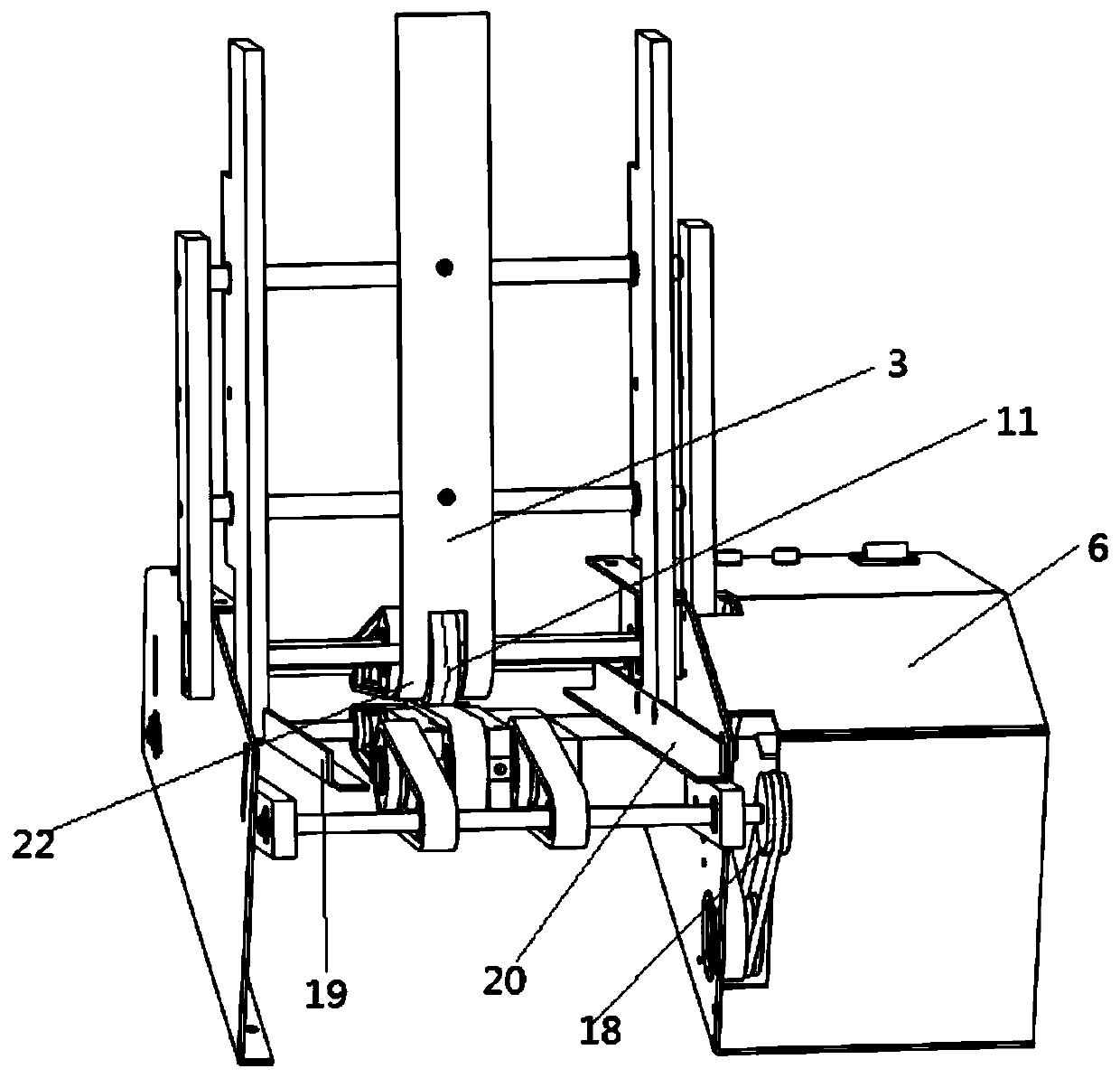

[0023] see Figure 1~5 , in an embodiment of the present invention, a cardboard creasing device for packaging box production, including a driving base 6, a fixed base 5, a cardboard feeding mechanism 7, a cardboard sending mechanism and an indentation mechanism, wherein the driving The machine base and the fixed machine base are arranged in parallel at intervals, and it is characterized in that the cardboard feeding mechanism 7 and the cardboard sending mechanism are sequentially arranged between the driving machine base 6 and the fixed machine base 5 from front to back. The creasing mechanism is arranged between the cardboard feeding mechanism 7 and the cardboard sending mechanism, wherein the cardboard sending mechanism 12 includes an upper cardboard sending mechanism 12 and a lower cardboard sending mechanism 13, and the upper cardboard sending mechanism 12 and the lower cardboard sending mechanism The upper and lower distances between the delivery mechanisms 13 are adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com