Magnetic force-based complex mold design and demolding method

A mold design and demoulding technology, which is applied in manufacturing tools, metal processing equipment, processing data acquisition/processing, etc., can solve the problem that the mold is difficult to take out the mold split part, etc., achieve less printing time, easy disassembly and assembly, and low molding cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

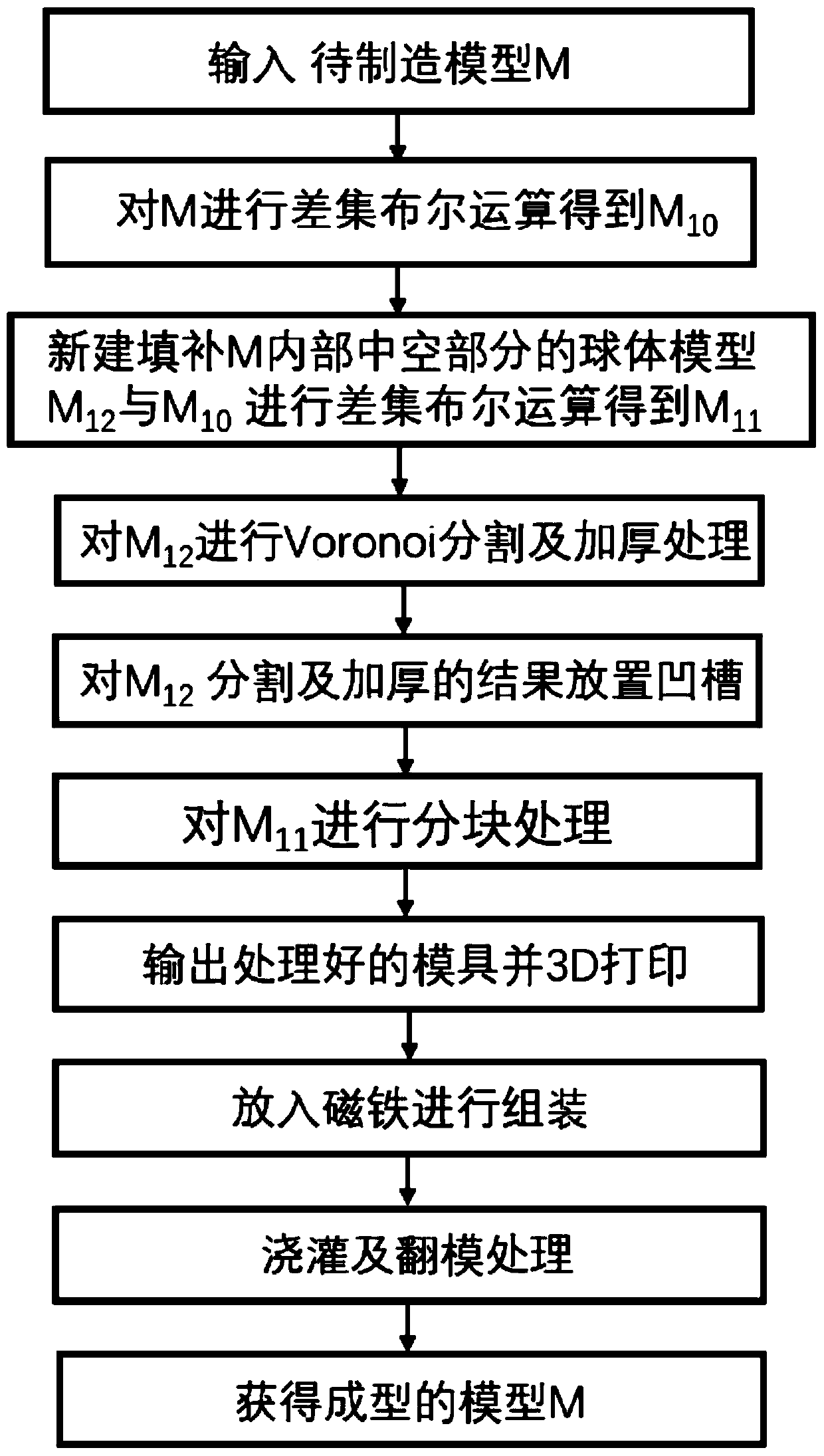

[0038] figure 1 It is a flow chart of a complex mold design and demoulding method based on magnetic force of the present invention.

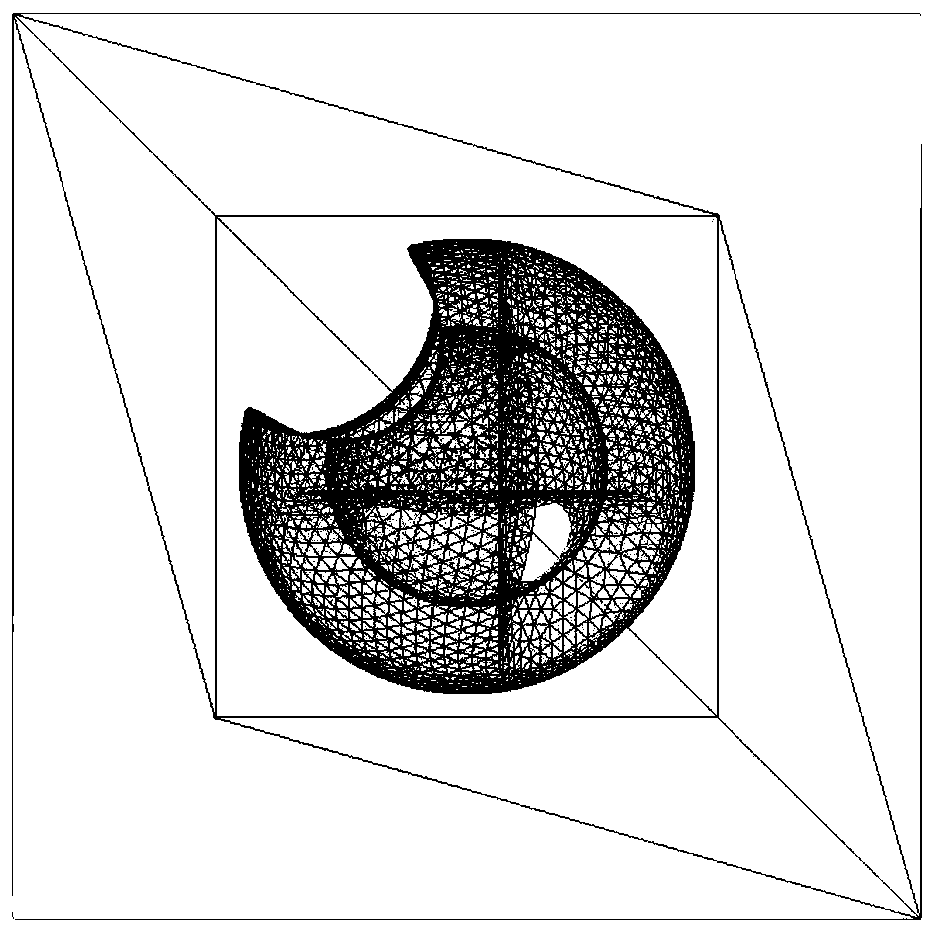

[0039] In this embodiment, M is used to represent the input model to be manufactured, as shown in the attached figure 2 shown.

[0040] Such as figure 1 Shown, a kind of complex mold design and demoulding method based on magnetic force of the present invention comprises:

[0041] Step (1): Input the model M to be manufactured, and obtain the initial mold M10 to be divided after the Boolean difference operation.

[0042] Among them, before performing Boolean operation processing on the input model M, it also includes:

[0043] Subdivide or simplify the grid input to the model M to a certain extent to avoid Boolean operation errors due to the grid being too sparse or too dense.

[0044] Among them, the specific proce...

Embodiment 2

[0076] A complex mold design and demoulding method based on magnetic force, comprising the following steps:

[0077] Input the model to be manufactured, and obtain the initial model after the difference operation; create the internal model of the model to be manufactured; obtain the external model after the difference operation between the initial model and the internal model;

[0078] Divide the internal model to form mold modules that can be taken out; grooves are provided on the splicing surface of each mold module, and magnets are placed in the grooves;

[0079] Divide the external model, and dig holes to get the material pouring port;

[0080] Set up the mold body, put magnets in the groove position for assembly, pour through the pouring port after assembly, and demould after cooling and solidification.

[0081] The specific steps of obtaining the initial model include: creating a simple model that can surround the model according to the model to be manufactured, using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com