Gravity casting-liquid forging combined casting device and process

A liquid die forging and gravity casting technology, which is applied in the field of casting technology, can solve the problems of high casting production cost, complex process, and huge equipment, and achieve the effects of fast casting speed, wide application range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

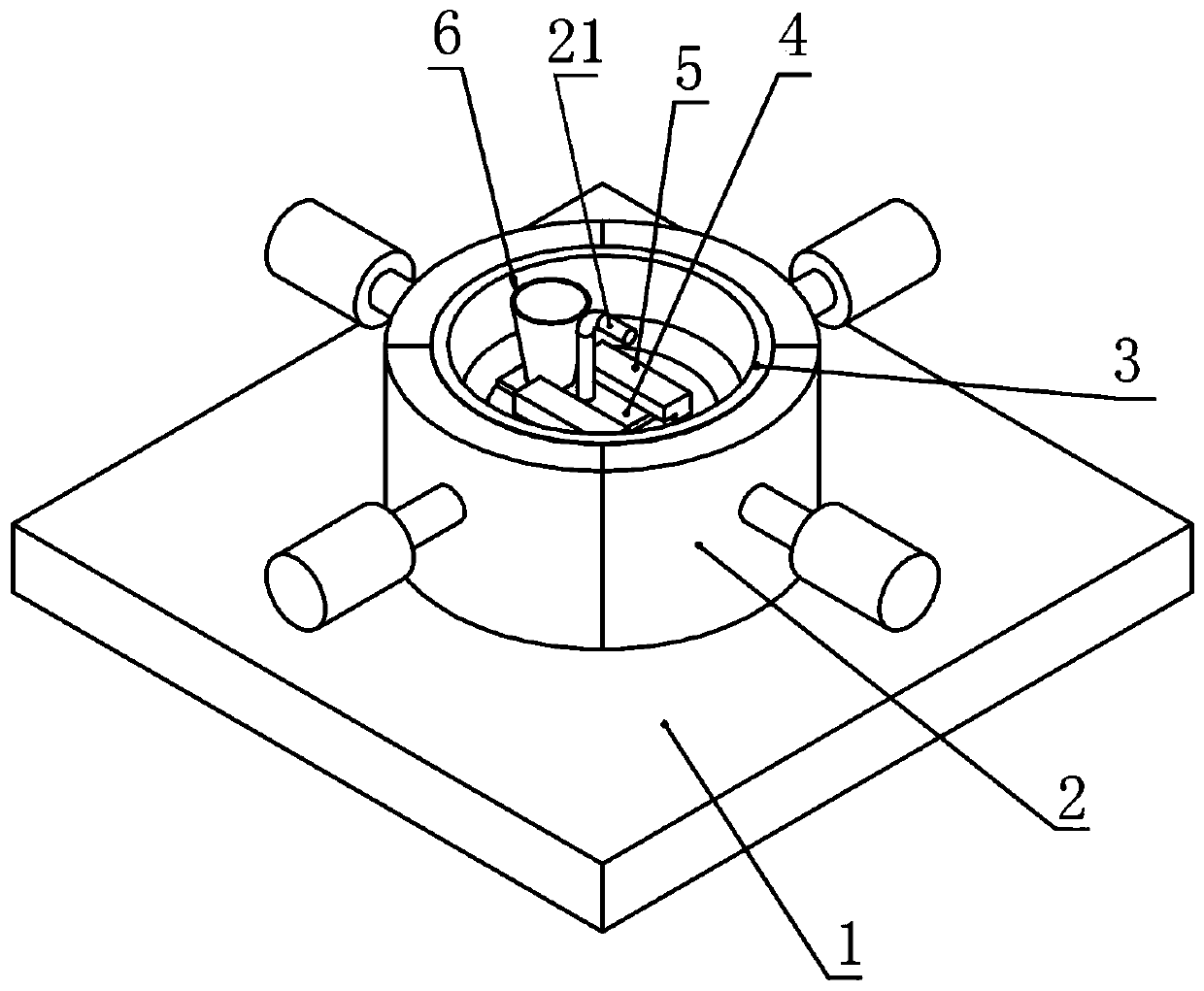

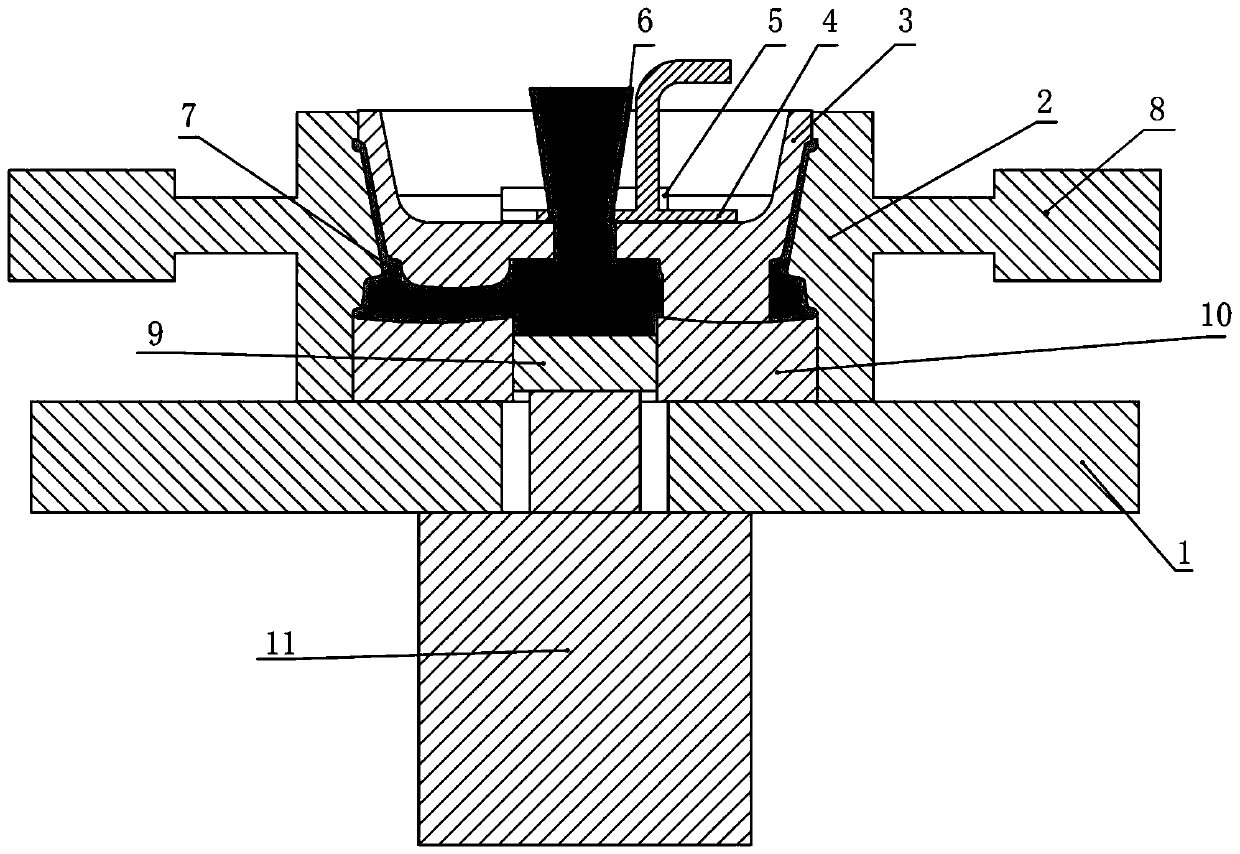

[0046] Such as Figure 1 to Figure 4 As shown, a casting device combining gravity casting and liquid forging, including a base 1, an upper mold 3, a side mold set 2, a movable mold 9, a sprue cup 6, a plugging slider 4, and a plugging chute 5. Pressurized oil cylinder 11; the base 1 is installed on the frame, and the lower surface of the base 1 is equipped with a pressurized oil cylinder 11, or the base 1 is installed on the ground, and the pressurized oil cylinder 11 is installed in the foundation pit below the ground , the piston rod of the pressurized cylinder 11 passes through the central hole of the base 1 and the end is fixedly installed with the lower surface of the movable mold 9, and the upper surface of the base 1 is respectively equipped with a fixed mold 10 and a side mold group 2, and the side mold group 2 A ring-shaped side module group 2 is formed by several side modules, and the outer surface of each side module is equipped with a mold opening and closing cylin...

Embodiment 2

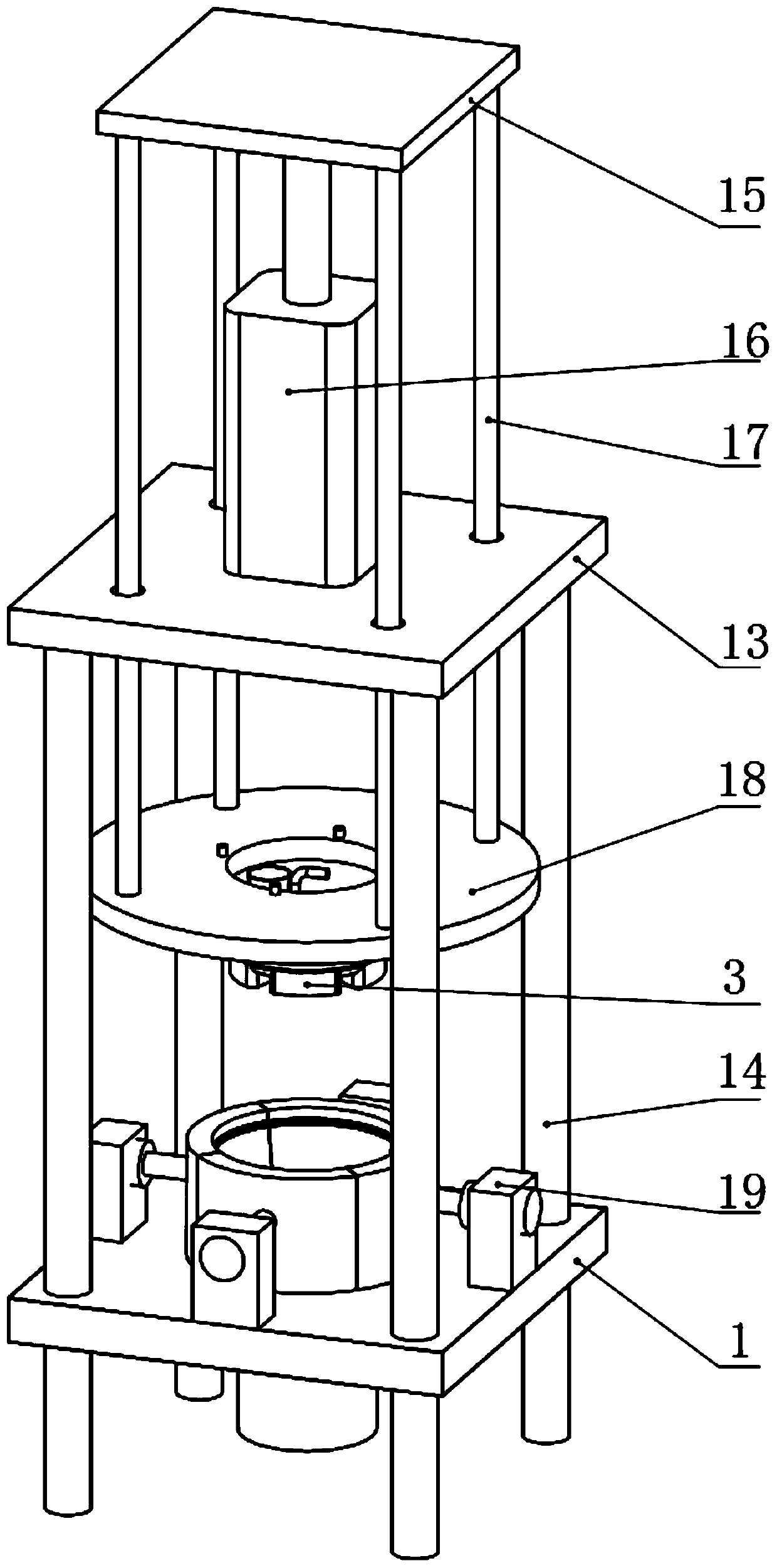

[0056] Such as Figure 5 to Figure 7 As shown, a casting device combining gravity casting and liquid forging, including a base 1, an upper mold 3, a side mold set 2, a moving mold 9, a sprue cup 6, a plugging slider 4, and a plugging chute 5 and a pressurized oil cylinder 11; the base 1 is installed on the frame, and the lower surface of the base 1 is equipped with a pressurized oil cylinder 11, or the base 1 is installed on the ground, and the pressurized oil cylinder 11 is installed in the foundation pit below the ground The end of the piston rod of the pressurized cylinder 11 passes through the center hole of the base 1 and the end is fixedly installed on the lower surface of the movable mold 9. The upper surface of the base 1 is equipped with a side module 2, and the side module 2 consists of two side modules. Composed, and the mold opening and closing cylinder 8 is installed on the outer circular surface of the side module, and the mold opening and closing cylinder 8 is f...

Embodiment 3

[0065] Such as Figure 8 to Figure 10As shown, a casting device combining gravity casting and liquid forging, including a base 1, an upper mold 3, a side mold set 2, a moving mold 9, a sprue cup 6, a plugging slider 4, and a plugging chute 5 and pressurized oil cylinder 11, described base 1 is installed on the frame, and pressurized oil cylinder 11 is installed on the lower surface of base, and described pressurized oil cylinder 11 is two, or base is installed on the ground, and pressurized oil cylinder 11 is installed in the foundation pit below the ground, the piston rods of the two pressurized oil cylinders 11 pass through the through holes on the base respectively, and the rear end is connected with the lower surface of the movable mold 9, and the upper surface of the base 1 is equipped with a side module 2, The side module group consists of two side modules to form a square side module group, and a mold opening and closing cylinder 8 is installed on the side wall where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com