Utility vehicle tyres

A technology for multi-purpose vehicles and tires, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as damage to groove walls and stone-discharging structures, prevent stone blockage, and improve stone-discharging effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Utility vehicle tires designed according to the invention are tires of radial design, in particular tires for construction site vehicles, trucks or buses.

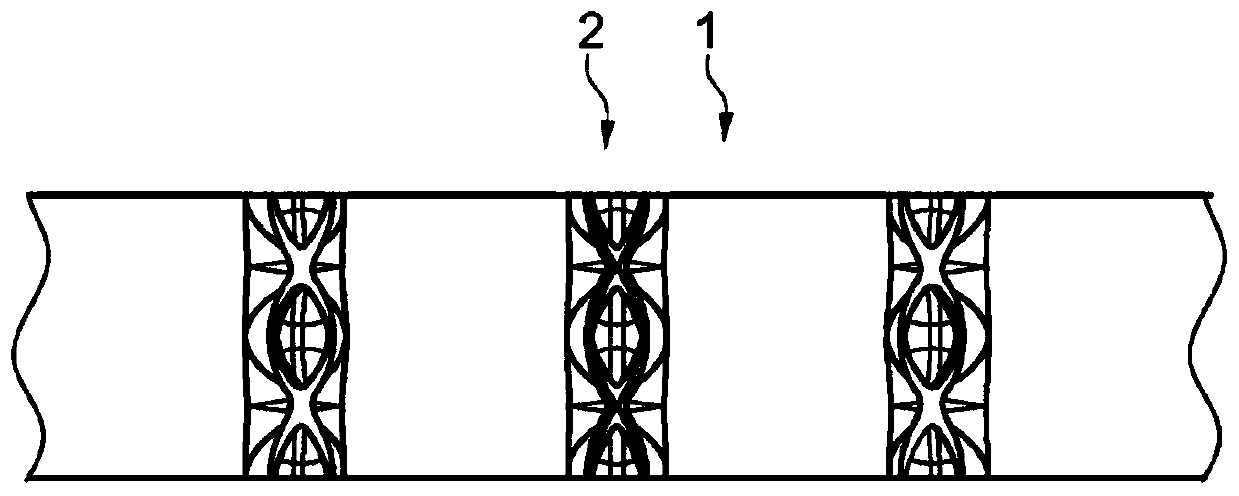

[0036] figure 1 The shown central circumferential section of the tread has a tread face 1 encircling in the circumferential direction a strip or block, shown schematically in simplified form and realized in particular in a known manner. Adjacent tread faces 1 in the axial direction are separated by respective circumferential grooves 2 extending linearly in plan view.

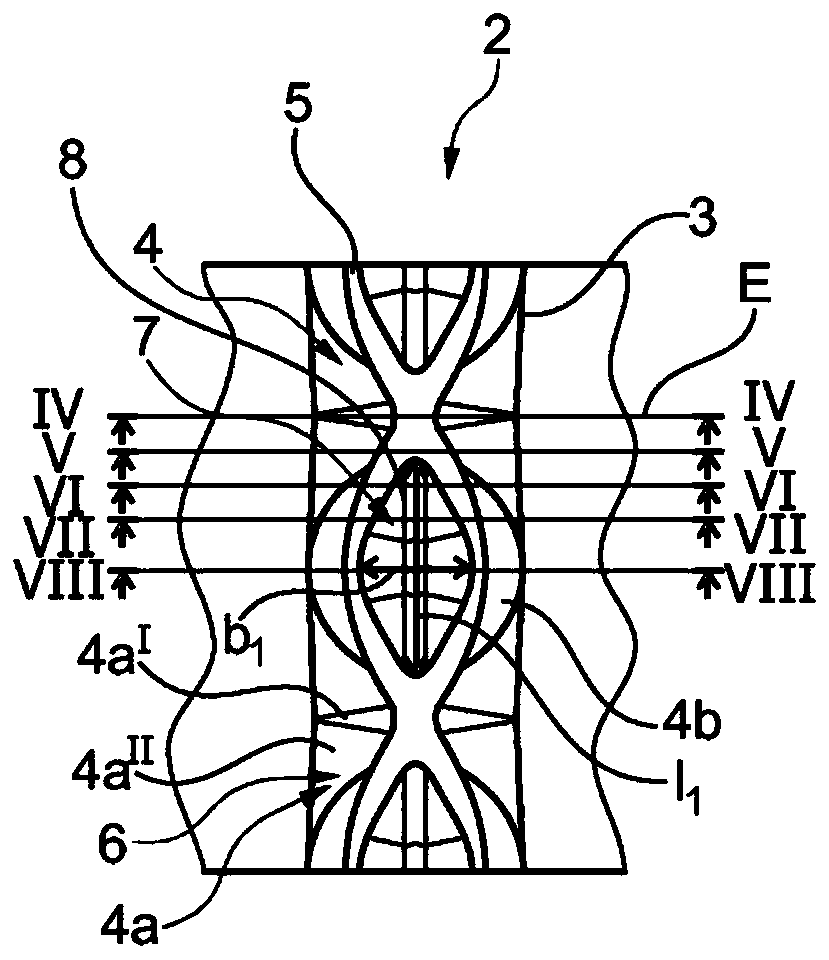

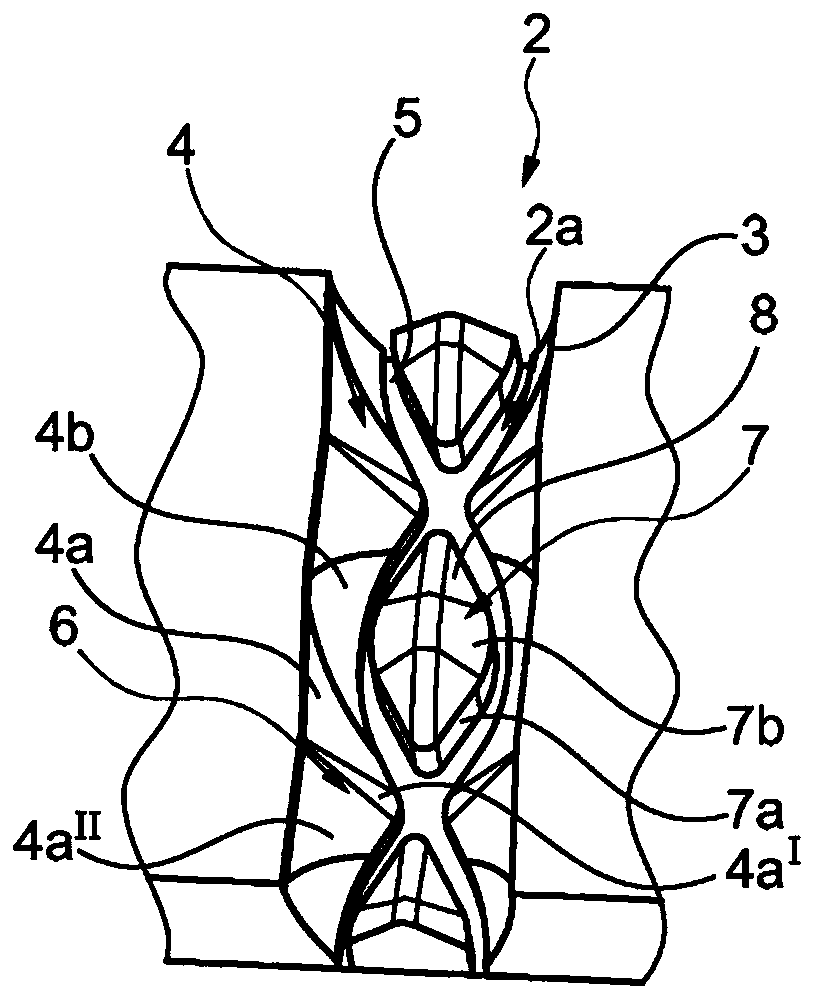

[0037] In the exemplary embodiment shown, the circumferential grooves 2 are designed in a corresponding manner. The following will refer to Figure 2 to Figure 8 The configuration of the circumferential groove 2 will be described with reference to the circumferential groove 2 shown in FIG.

[0038] Such as figure 2 and image 3As shown, a circumferential sipe 2 at the periphery of the tread is delimited by two sipe edges 3 which extend substanti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extension length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com