Preparation and Application of Electrode Containing Tin Array Structure

An array structure and electrode technology, applied in the field of electrode preparation and application, can solve the problems of low negative electrode capacity, poor cycle stability, etc., and achieve the effect of improving electrical contact, improving cycle stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

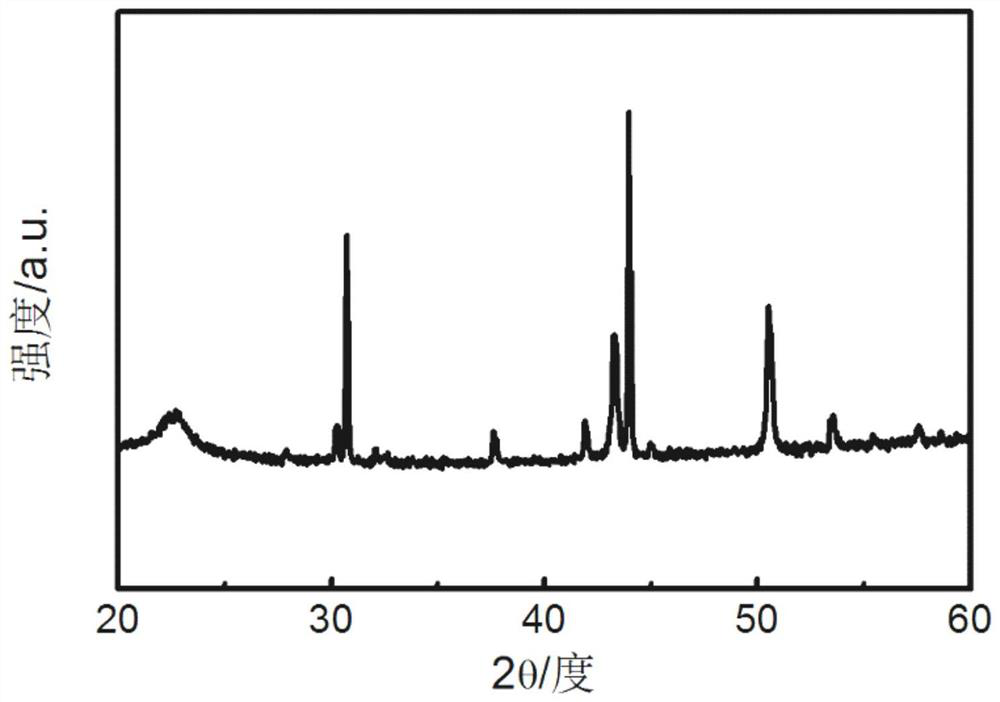

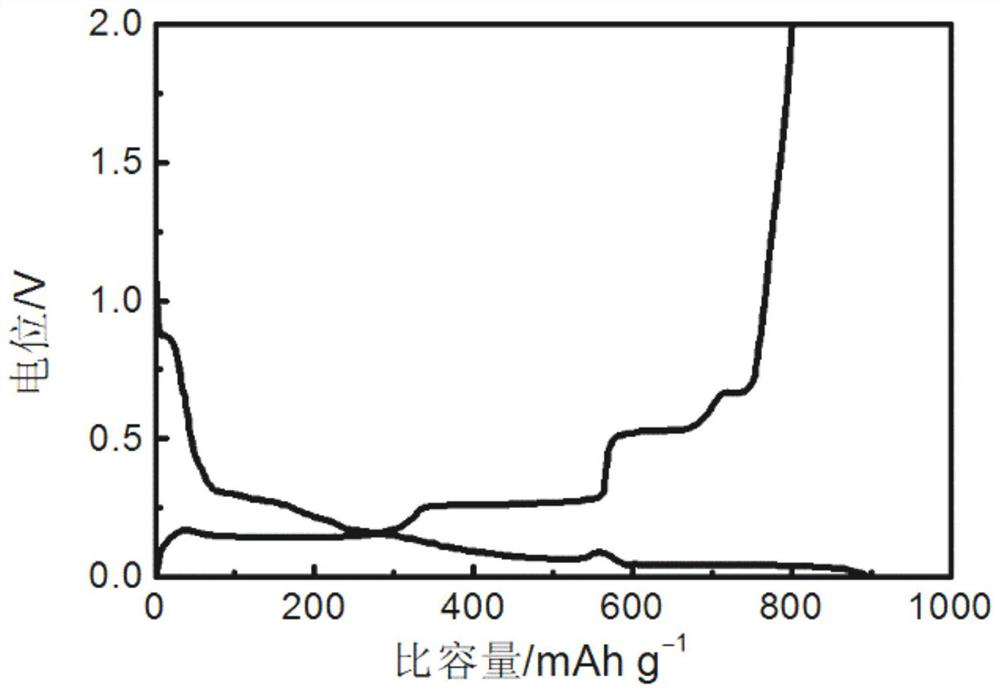

Image

Examples

Embodiment 1

[0043] Take a 2cm×0.5cm copper sheet and ultrasonically clean it in oxalic acid solution, deionized water and alcohol for 10 minutes. With the cleaned copper sheet as the working electrode and the carbon electrode as the counter electrode, the electrolyte is composed of 0.06M tin tetrachloride pentahydrate and 0.12M trisodium citrate solution, and the electrolyte solvent is ethylene glycol and water (volume The ratio is 1:1), using a three-electrode system at 0.01A cm -2 Electrodeposition was performed for 20 minutes at a current density to deposit a tin array structure on the surface of the copper substrate. The copper substrate deposited with the tin array structure was annealed, the protective atmosphere used was argon, the temperature was 180° C., and the time was 2 hours to obtain a negative electrode with a tin array structure with a height of about 3 μm.

[0044] The negative electrode containing tin array structure (hereinafter referred to as tin array negative electr...

Embodiment 2

[0046] Take a 2cm×0.5cm copper sheet and ultrasonically clean it in oxalic acid solution, deionized water and alcohol for 10 minutes. With the cleaned copper sheet as the working electrode and the carbon electrode as the counter electrode, the electrolyte is composed of 0.2M tin tetrachloride pentahydrate and 0.2M polyvinylpyrrolidone solution, and the electrolyte solvent is ethylene glycol and water (volume ratio 1:1), using a three-electrode system at 0.01A cm -2 Depositing at a current density of 5 min to deposit a tin array structure on the surface of the copper substrate. The copper substrate deposited with the tin array structure was annealed at 220° C. for 2 hours under the protection of argon to obtain a tin array negative electrode with a height of about 5 μm.

[0047] The tin array negative electrode was tested for sodium storage performance according to the above method, and the results showed that the reversible sodium storage capacity of the obtained tin array ne...

Embodiment 3

[0049] Take a 2cm×1cm copper sheet and ultrasonically clean it in oxalic acid solution, deionized water and alcohol for 10 minutes. The cleaned copper sheet is used as the working electrode, and the carbon electrode is used as the counter electrode. The electrolyte is composed of 0.1M tin tetrachloride pentahydrate, 0.1M stannous chloride and 0.4M ethylenediamine hydrochloride. The electrolyte solvent is Diethylene glycol and water (volume ratio 1:2), using a three-electrode system at 0.04A cm -2 Electrodeposition was carried out for 10 minutes at a current density to deposit a tin array structure on the surface of the copper substrate. Then vacuum annealing was performed on the copper substrate deposited with the tin array structure, the annealing temperature was 200° C., and the time was 30 min to obtain a tin array negative electrode with a height of about 10 μm.

[0050] The tin array negative electrode was tested for sodium storage performance according to the above meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com