Multi-heat exchanger series transcritical CO2 heat pump heating system

A heating system and heat exchanger technology, applied in the field of multi-heat exchanger series transcritical CO2 heat pump heating system, can solve the problems such as the need to improve the uniformity of heat exchange, the decrease of heating efficiency, and the increase of the outlet temperature of an air cooler, Achieve the effect of improving the uniformity of heat exchange, reducing the irreversible loss of heat exchange, and improving the total energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

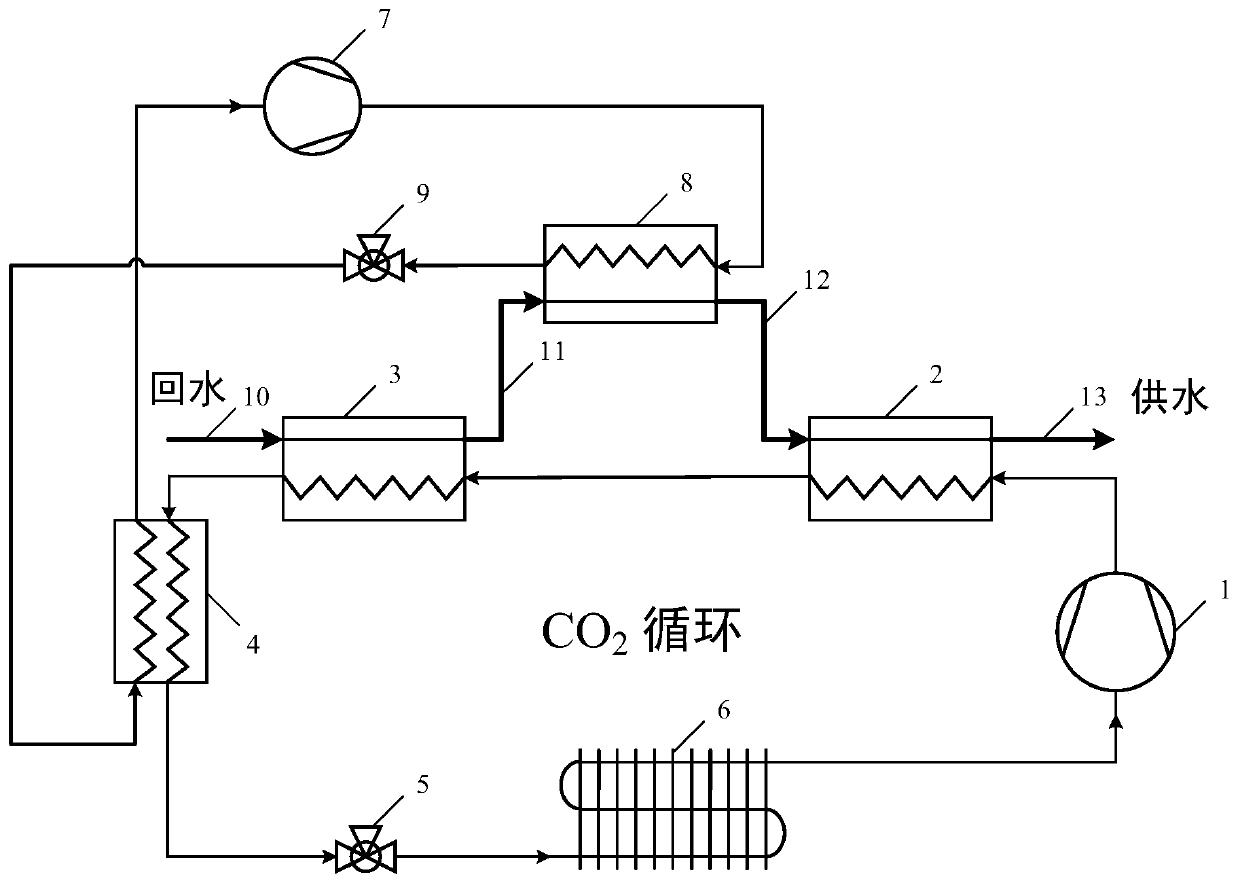

[0036] refer to figure 1 , this embodiment provides a multi-heat exchanger series transcritical CO 2 Heat pump heating system, including first compressor 1, first air cooler 2, second air cooler 3, cooling evaporator 4, first throttling device 5, low temperature evaporator 6, second compressor 7, condenser 8 and the second throttling device 9,

[0037] The first air cooler 2, the second air cooler 3 and the condenser 8 are all refrigerant-brine heat exchangers, equipped with refrigerant passages and brine passages, and the cooling evaporator 4 is a refrigerant - a refrigerant heat exchanger with dual refrigerant passages, the low-temperature evaporator 6 is a refrigerant-air heat exchanger with refrigerant passages and air passages,

[0038] The exhaust port of the first compressor 1, the refrigerant passage of the first air cooler 2, the refrigerant passage of the second air cooler 3, one of the refrigerant passages of the cooling evaporator 4, the first throttling device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com