Production process of chondroitin and bone paste

A production process and chondroitin technology, applied in the field of chondroitin and bone pulp production process, can solve problems such as low production efficiency, easy environmental pollution, rough process, etc., achieve high production efficiency, avoid environmental pollution, and improve production and processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

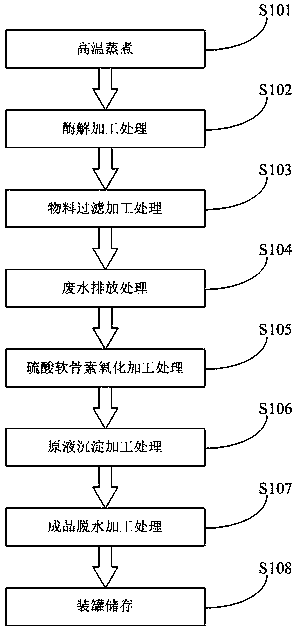

[0037] as attached figure 1 shown

[0038] A kind of chondroitin and bone pulp comprises the following raw materials in parts by weight, bone pulp 20g-30g, cartilage 20g-30g, water 15g-20g, sodium hydroxide 20g-25g, protease 25g- 30 grams, 30 grams to 35 grams of sodium chloride, 15 grams to 20 grams of alcohol, 25 grams to 30 grams of hydrochloric acid and 10 grams to 15 grams of enzymatic hydrolysis powder.

[0039] Preferably, the cartilage is bovine cartilage, porcine cartilage or sheep cartilage, and the enzymatic hydrolysis powder is porcine pancreas grinding powder or axillary enzyme powder.

[0040] A kind of production technology of chondroitin and bone pulp comprises the following steps:

[0041] S101: high-temperature cooking, pouring bone pulp and cartilage into a reaction kettle and adding water for high-temperature cooking to obtain bone liquid;

[0042] S102: Enzymatic hydrolysis processing, add enzymatic hydrolysis powder and stir evenly, then carry out enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com