A kind of Clivia fertilizer hemp seed cooking equipment

A technology of hemp seeds and Clivia, applied in the field of Clivia fertilizer hemp seeds cooking equipment, can solve the problems of low processing efficiency, low degree of automation of the cooking process, time-consuming and labor-intensive, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

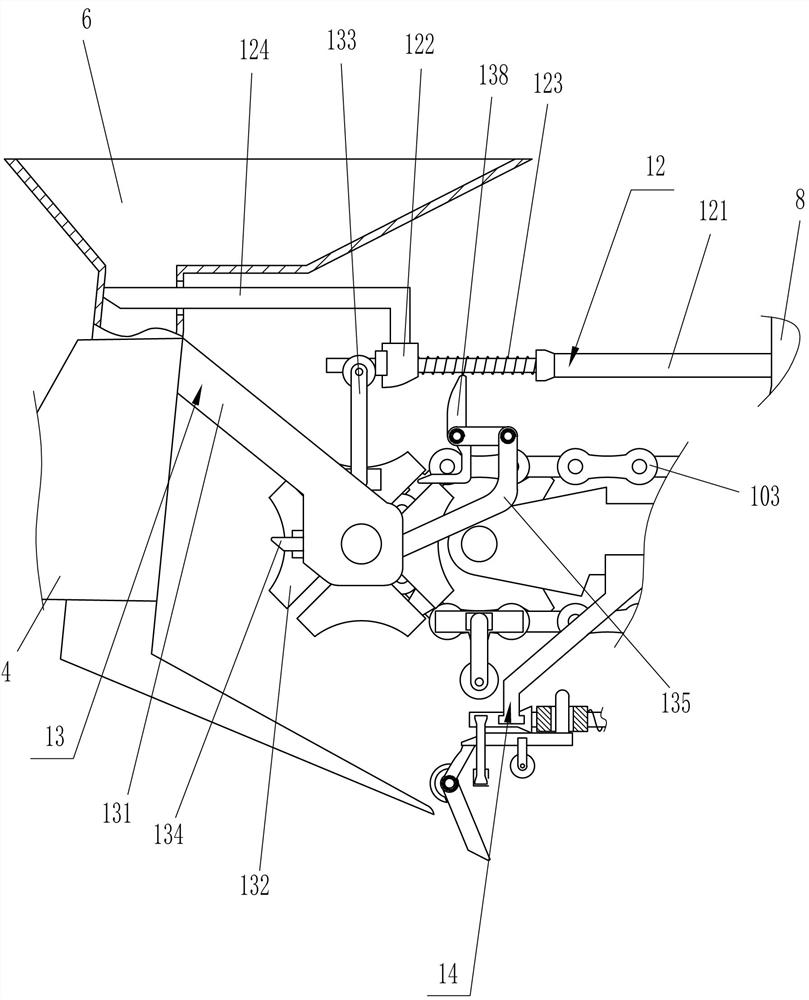

[0028] A kind of Clivia fertilizer hemp seed cooking equipment, such as figure 1 As shown, it includes a bottom plate 1, a collection box 2, a heater 3, a fixing frame 4, a placing device 5, a blanking box 6, a support frame 7, a bracket 8, a mounting plate 9, a driving device 10, a driving motor 11, a blanking Device 12 and control device 13, a collection box 2 is placed on the right side of the bottom plate 1, a heater 3 is installed on the bottom plate 1, a fixing frame 4 is connected on the left side of the bottom plate 1, and the fixing frame 4 is on the A placing device 5 is provided on the side, and the placing device 5 is located above the heater 3 . The upper side of the fixing frame 4 is connected with a feeding box 6 , and the feeding position of the feeding box 6 is located at the upper left of the placing device 5 , a support frame 7 is connected on the right side of the bottom plate 1, the support frame 7 is located above the placement device 5 and is connected w...

Embodiment 2

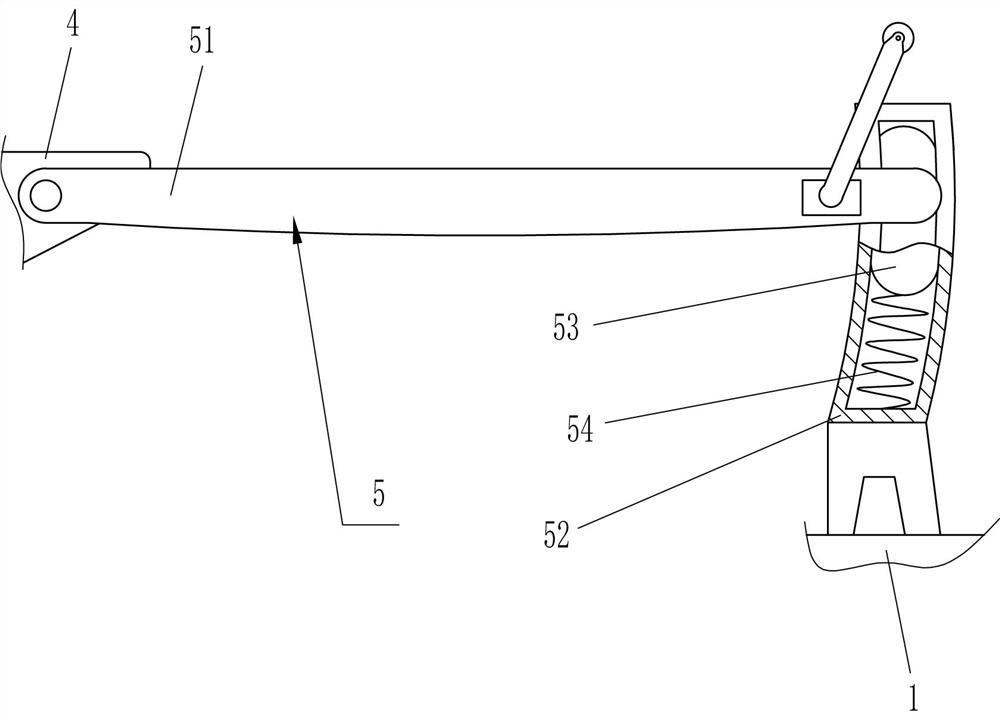

[0031] On the basis of Example 1, as Figure 2-5 As shown, the placing device 5 includes a placing plate 51, an arc-shaped slide rail 52, a sliding block 53 and a first elastic member 54. The middle part of the right side of the fixing frame 4 is rotatably connected with the placing plate 51. An arc-shaped slide rail 52 is connected to the side, a slider 53 is slidably connected to the arc-shaped slide rail 52 , and a first elastic member 54 is connected between the lower side of the slider 53 and the arc-shaped slide rail 52 . The front side of the slider 53 is connected to the placing plate 51 , and the placing plate 51 is located above the heater 3 .

[0032] The heater 3 heats the placement plate 51, the hemp seeds in the unloading box 6 will fall on the placement plate 51, the hemp seeds on the placement plate 51 can be turned over, and the control device 13 The placing plate 51 is pressed downward just after a controlled feeding and cooking cycle is completed, and the p...

Embodiment 3

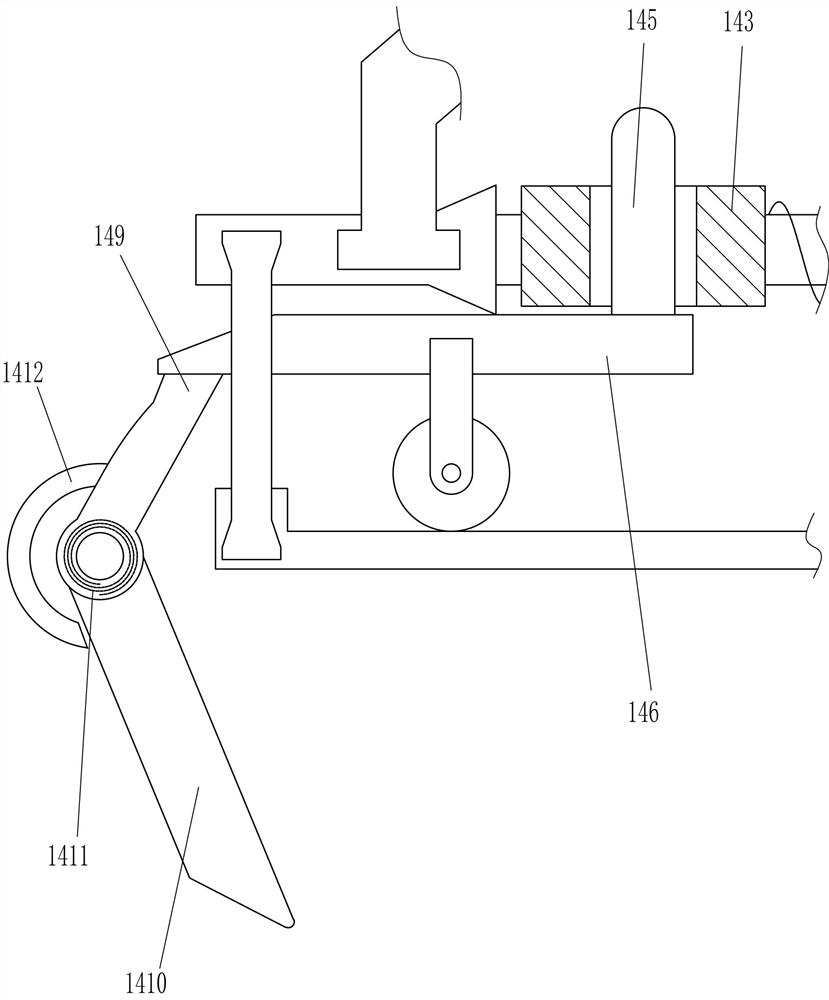

[0040] On the basis of Example 2, as Figure 6-10 As shown, it also includes a flipping device 14, and a flipping device 14 is provided below the mounting plate 9. The flipping device 14 includes a support rod 141, a second guide rail 142, a double-hole guide sleeve 143, a fifth elastic member 144, The force-bearing rod 145, the extension rod 146, the roller 147, the guide frame 148, the connecting seat 149, the flip plate 1410, the sixth elastic member 1411, the blocking rod 1412 and the moving wheel 1413, the front side of the mounting plate 9 is connected with the left and right sides. A support rod 141, a second guide rail 142 is connected between the lower side of the support rod 141, a double-hole guide sleeve 143 is slidably connected to the second guide rail 142, and the double-hole guide sleeve 143 is right on the second guide rail 142. A fifth elastic member 144 is connected between the sides, a force-bearing rod 145 is slidably connected to the front side hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com