A device for removing burrs in high-precision pipelines with built-in impedance

A technology of cleaning device and impedance, which is applied in the field of high-frequency welding equipment, can solve the problems of loose fit between the blade and weld burrs, non-concentrated magnetic force lines, and narrow application range, so as to improve the quality of cleaning, concentrate the magnetic force lines, and improve The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

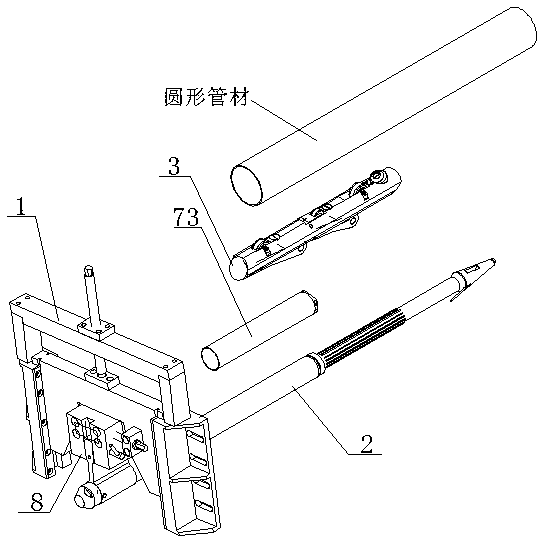

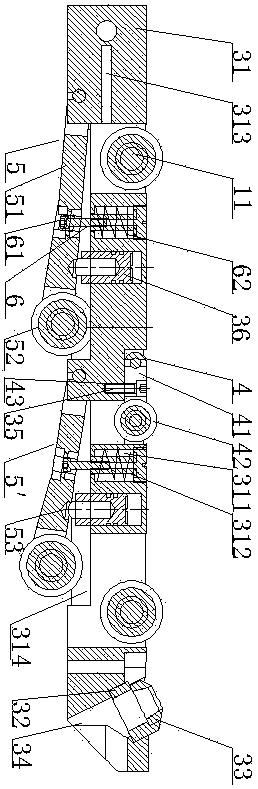

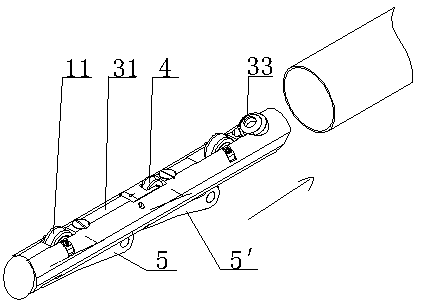

[0036] Such as Figures 1 to 8 As shown, the present invention includes a double-roller deburring device 3 and an impedance device 2. One end of the impedance device 2 is inserted into the double-roller deburring device 3, and the opposite end is connected to the production equipment through a fixed frame 1 with an adjustable angle. The double-roller deburring device 3 includes a knife bar body 31, the knife bar body 31 is provided with a fixed knife rest 32, the fixed knife rest 32 is provided with a cutting blade 33, and the knife bar body 31 behind the fixed knife rest 32 is provided with a chip removal through hole 34, the knife The rod body 31 is also provided with an upper roller positioning device 4, a lower roller positioning device A5, and a lower roller positioning device B5', and the upper roller positioning device 4, the lower roller positioning device A5, and the lower roller positioning device B5' are corresponding to the cutter bar body 31 The position is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com