Method for improving positioning strength of built-in clamp

A strength and fixture technology, applied in the field of automobile body-in-white, which can solve the problem of insufficient positioning strength of built-in fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

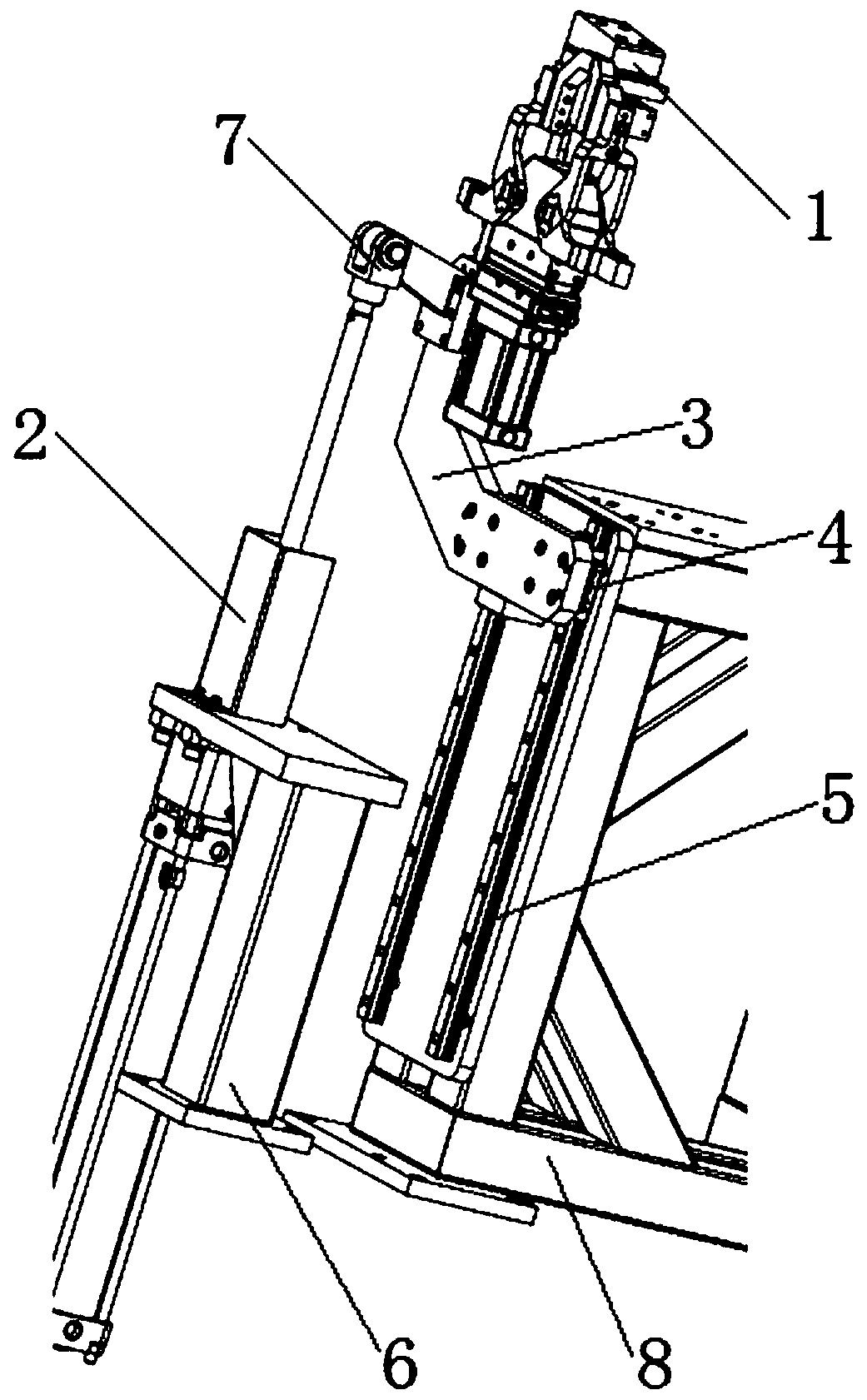

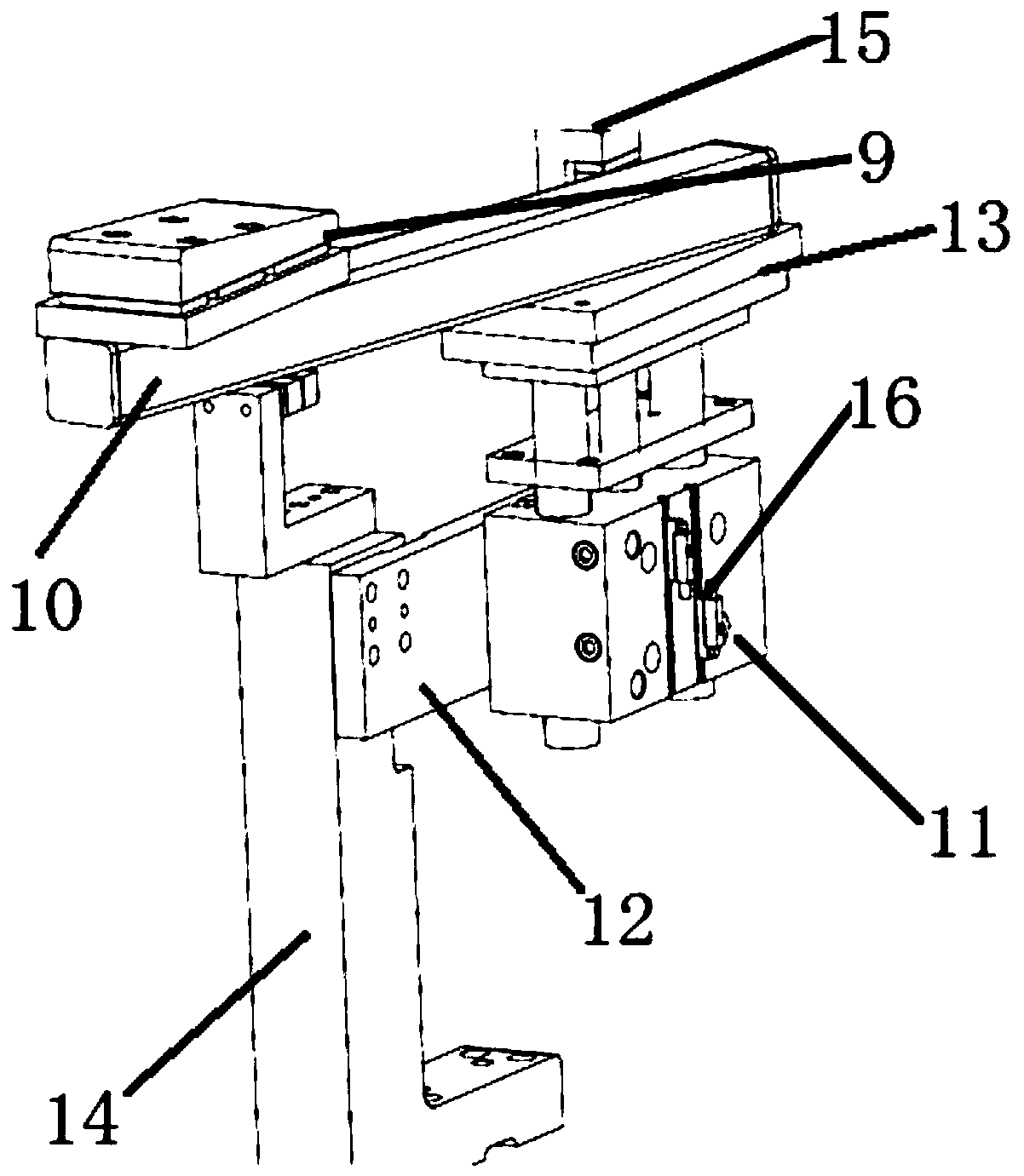

Embodiment Construction

[0017] A method for improving the positioning strength of a built-in fixture, the method comprising the following steps:

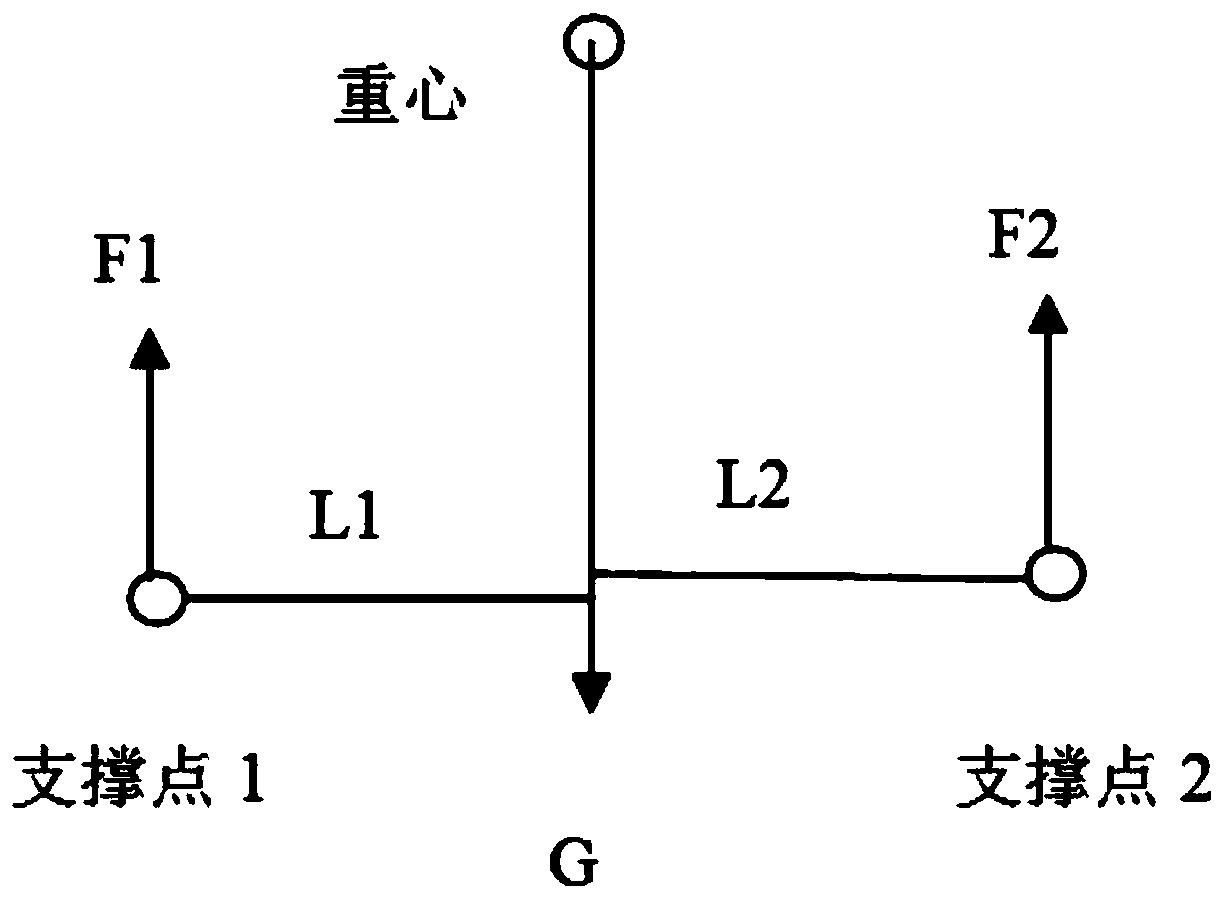

[0018] Step 1. Set the fixed positions of the first support unit and the second support unit on both sides of the center of gravity of the side panel assembly, and select the support position within the range of 1 / 4 threshold to 1 / 3 threshold from the center of gravity on both sides of the center of gravity;

[0019] Step 2. Calculate the support force F1 of the first support unit and the support force F2 of the second support unit according to the fixed positions of the first support unit and the second support unit, and calculate the support force F1 of the first support unit and the support force F2 of the second support unit The support force F2 selects the cylinder and the pressure control valve required by the first support unit and the second support unit;

[0020] refer to figure 1 , the supporting force F1 of the first supporting unit and the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com