Automatic laser welding equipment with slide guide rail

A technology of automatic welding and welding equipment, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of insufficient production capacity, high wages of welding technicians, and increased product cost, so as to reduce processing links and facilitate operation. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

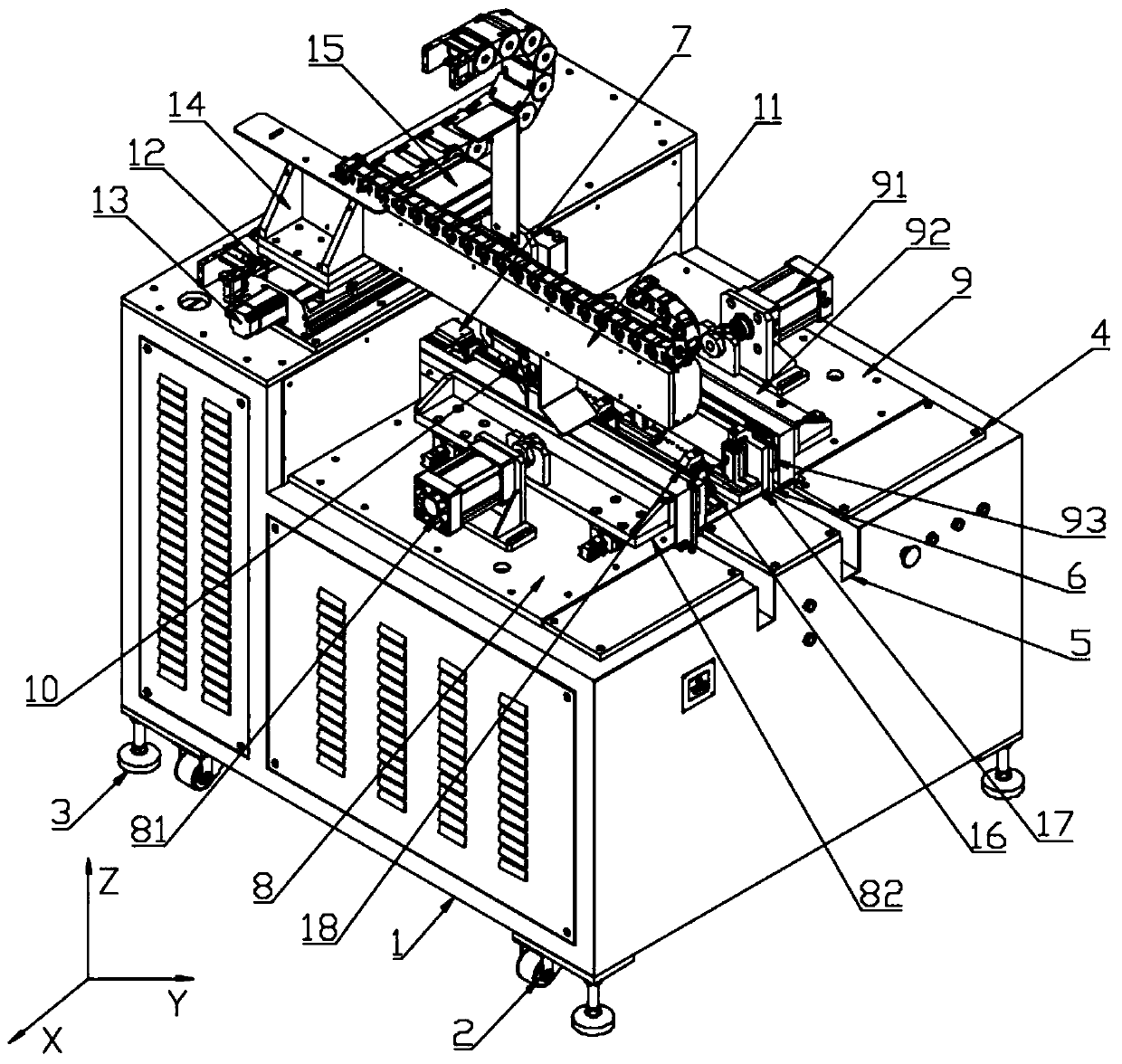

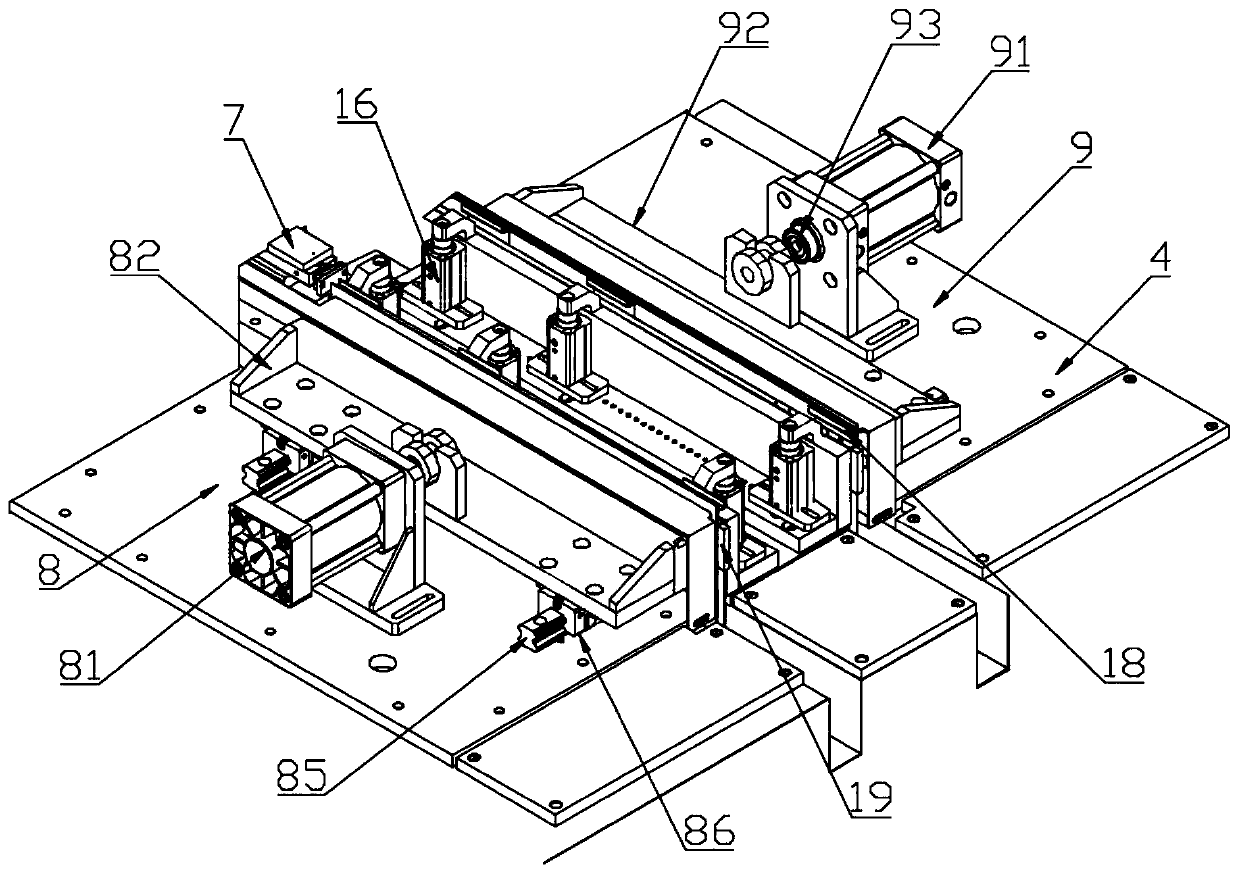

[0024] see figure 1 As shown, a laser automatic welding equipment with sliding guide rails includes a welding equipment box 1, a support plate 4, a left welding tool 8, a right welding tool 9 and a laser welding head 10. The welding equipment box 1 A support plate 4 is installed on the top, and the support plate 4 is divided into left and right double stations for welding, which are the left welding tool 8 and the right welding tool 9 respectively. The left welding tool 8 and the right welding tool 9 are provided with The laser welding head 10 is installed on the XY axis moving frame.

[0025] In order to improve the convenience of moving the welding equipment box 1 and the stability of placement, in the embodiment of the present invention, the four corners of the bottom of the welding equipment box 1 are installed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com