Plastic plate cleaning technology and device

A cleaning device and rubber sheet technology, applied in the direction of drying gas arrangement, cleaning method and tools, cleaning method using tools, etc., can solve problems such as difficult cleaning, easy adhesion on rubber sheet, difficulty in large-scale production, etc. Achieve good effect and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

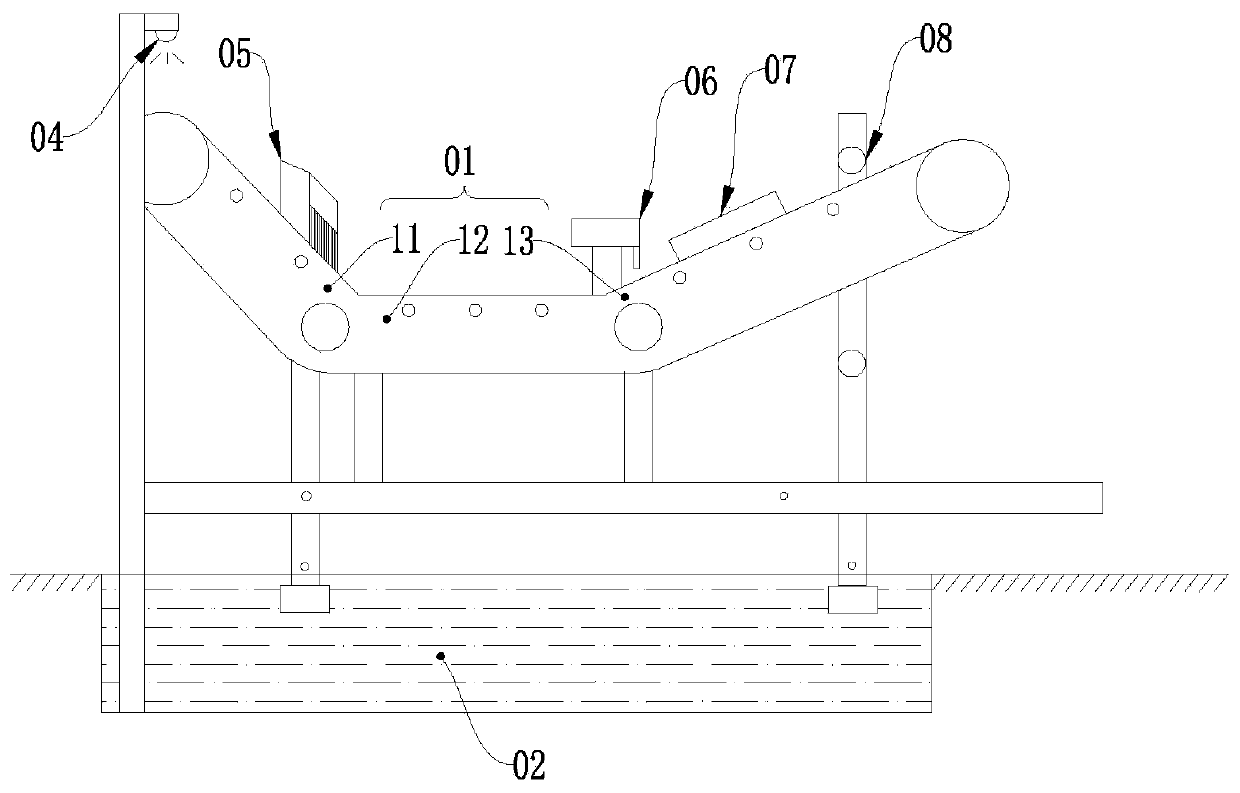

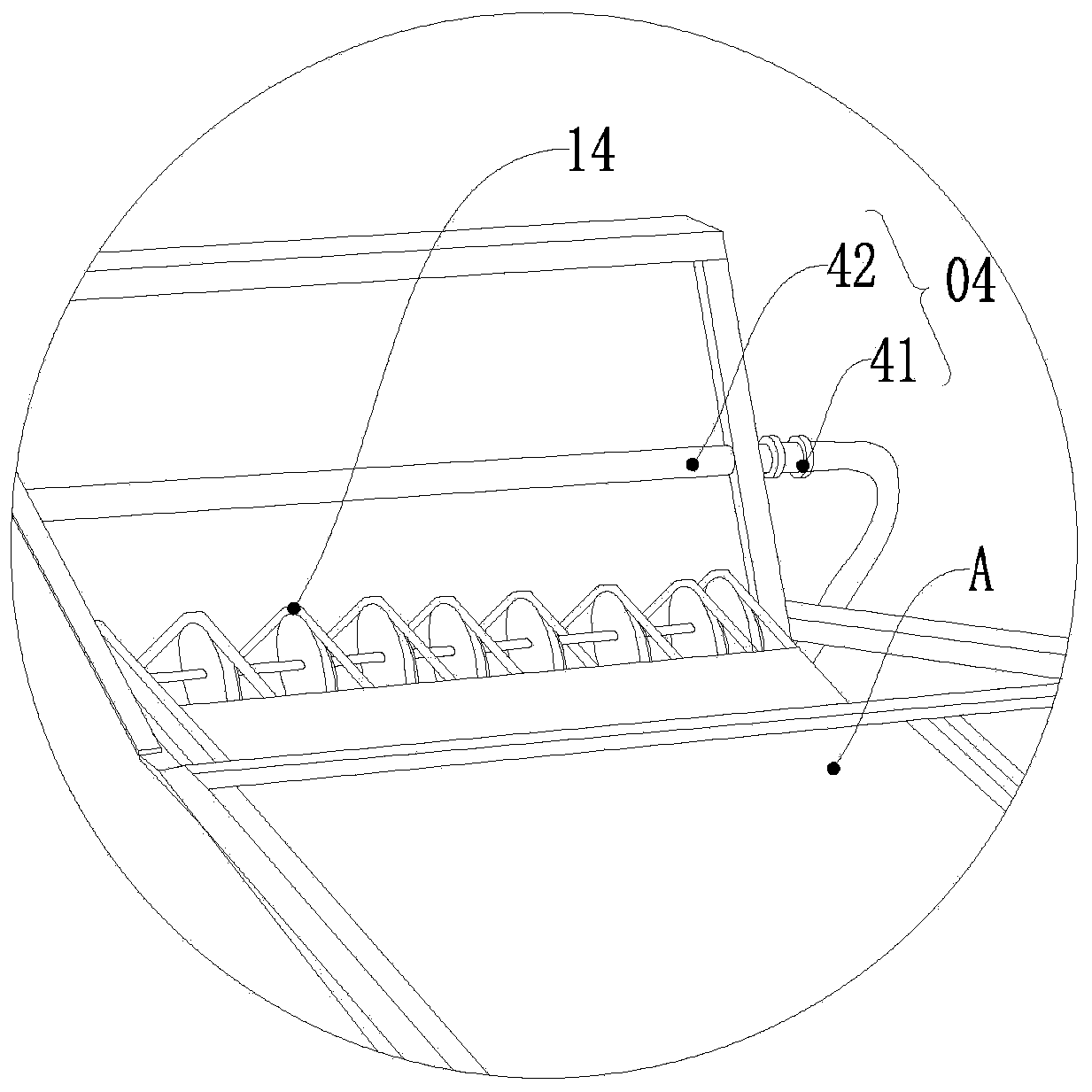

[0040] The invention provides a rubber sheet cleaning device, comprising a fixed bracket 01, a sewage pool 02 and a conveyor belt 03, the fixed bracket 01 is arranged above the sewage pool 02, and the fixed bracket 01 is provided with a drive shaft 14 and A plurality of rollers 15, the driving shaft 14 is arranged at one end of the conveyor belt 03, used to drive the conveyor belt 03 to rotate, the rollers 15 are used to tension and support the conveyor belt 03, and follow the conveyor belt 03 to rotate; the conveyor belt 03 are arranged side by side; it also includes a spray assembly 04, a brush assembly 05, a water absorption assembly 07 and an air drying assembly 08 arranged on the fixed support 01 in sequence according to the conveying direction of the conveyor belt 03;

[0041] The primary spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com