Environment-friendly crushing device for mineral primary processing

A crushing device and environment-friendly technology, which is applied in the field of environment-friendly crushing devices for primary mineral processing, can solve the problems that local minerals cannot be crushed, the crushing shaft cannot be accurately achieved, and the crushing quality is not high, so as to achieve comprehensive crushing and environmental protection. Good performance, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

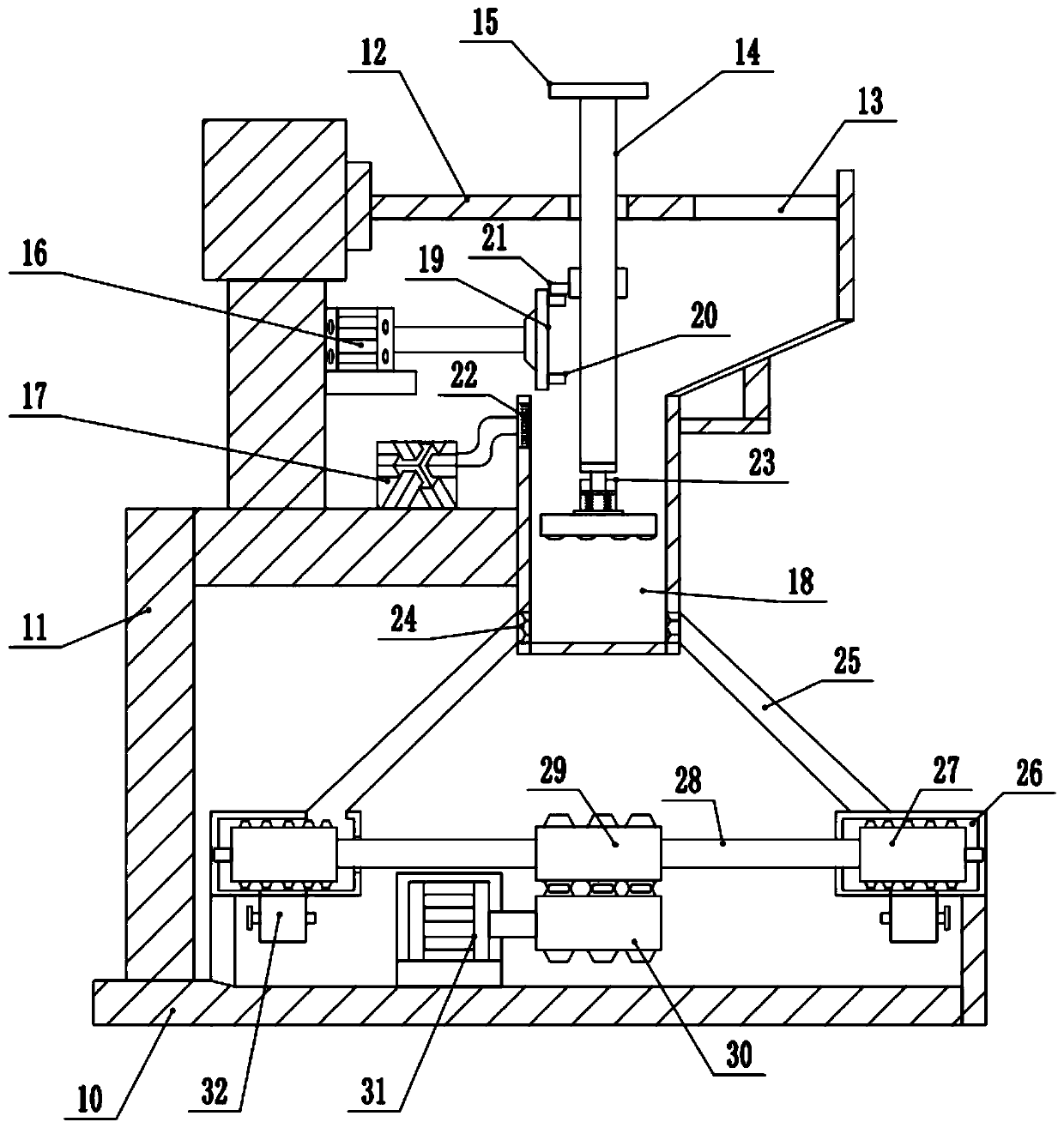

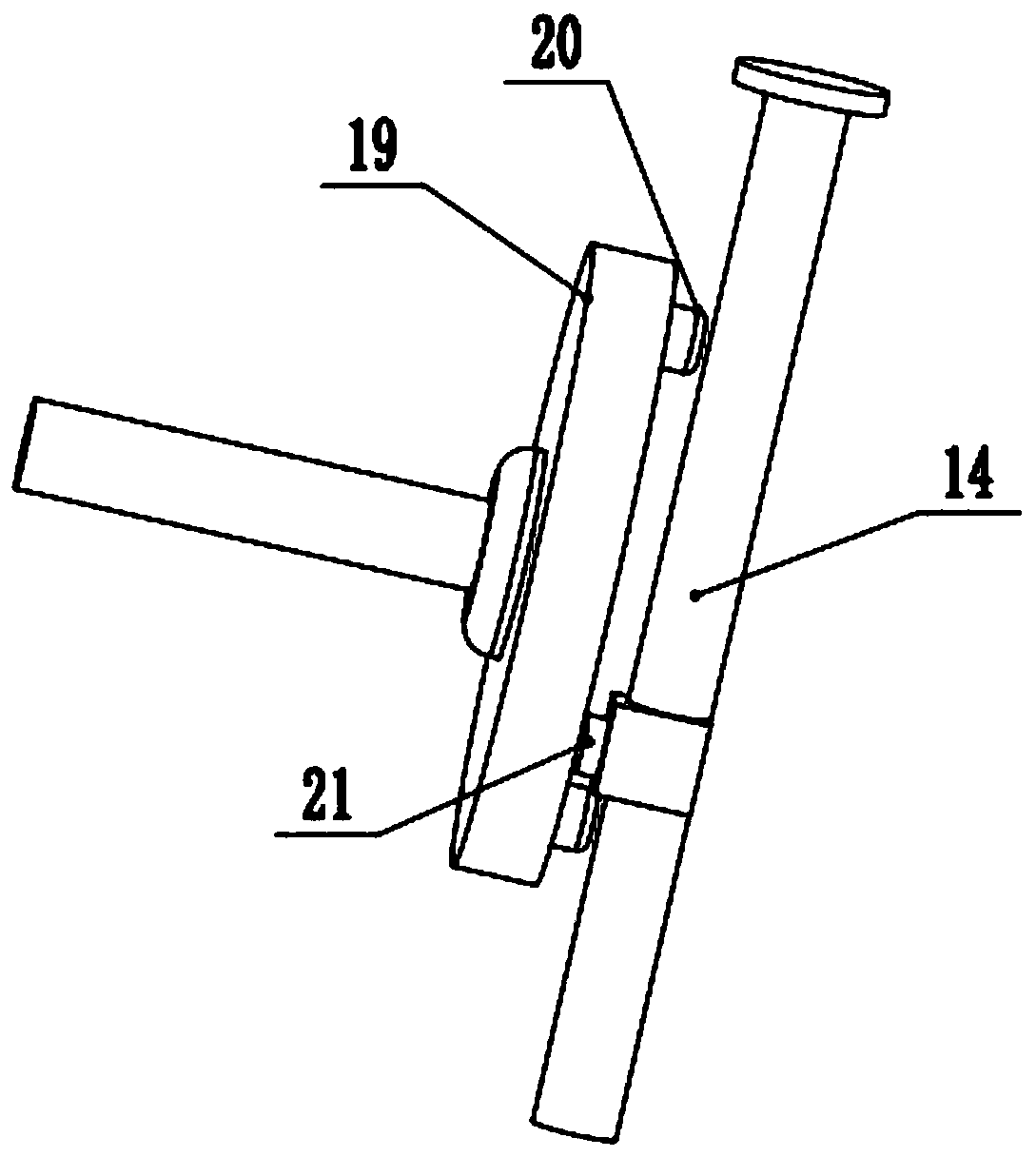

[0019] see Figure 1-3 , an environment-friendly crushing device for primary processing of minerals, comprising a base 10, a bracket 11, a feed inlet 13, a primary crushing cavity 18, a secondary crushing cavity 26, and a discharge port 32; the bracket 11 is fixedly installed on the left side of the base 10 On the top, the right side wall of the top of the bracket 11 is fixedly installed with a horizontal bar 12, and the right end of the bar 12 is provided with a feed port 13 for minerals to enter downwards, and the bottom of the feed port 13 communicates with a primary crushing chamber downwards. 18. A set of hammer plates 33 are arranged inside the primary crushing chamber 18 , and the bottom of the hammer plates 33 is provided with a corrugated structure to increase the friction between the bottom of the hammer plates 33 and the minerals inside the primary crushing chamber 18 . The top of the hammer plate 33 is fixed with a vertical telescopic rod 14, and the top of the tel...

Embodiment 2

[0024] On the basis of Embodiment 1, a buffer chamber 23 is fixedly installed, and a group of pressing plates 35 are arranged inside the buffer chamber 23. A group of vertical telescopic rods 14 are fixedly connected through the connecting rods. By setting a buffer chamber 23 between the hammer plate 33 and the telescopic rods 14, the buffering part can be slowed down when the hammer plate 33 touches the bottom of the primary crushing chamber 18 in an instant. impact force to protect the hammer plate 33 and the primary crushing chamber 18 for safe use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com