Probiotic solid beverage and preparation method thereof

A technology of solid beverages and probiotics, applied in the direction of bacteria, lactobacilli, bifidobacteria, etc. used in food preparation, can solve problems that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

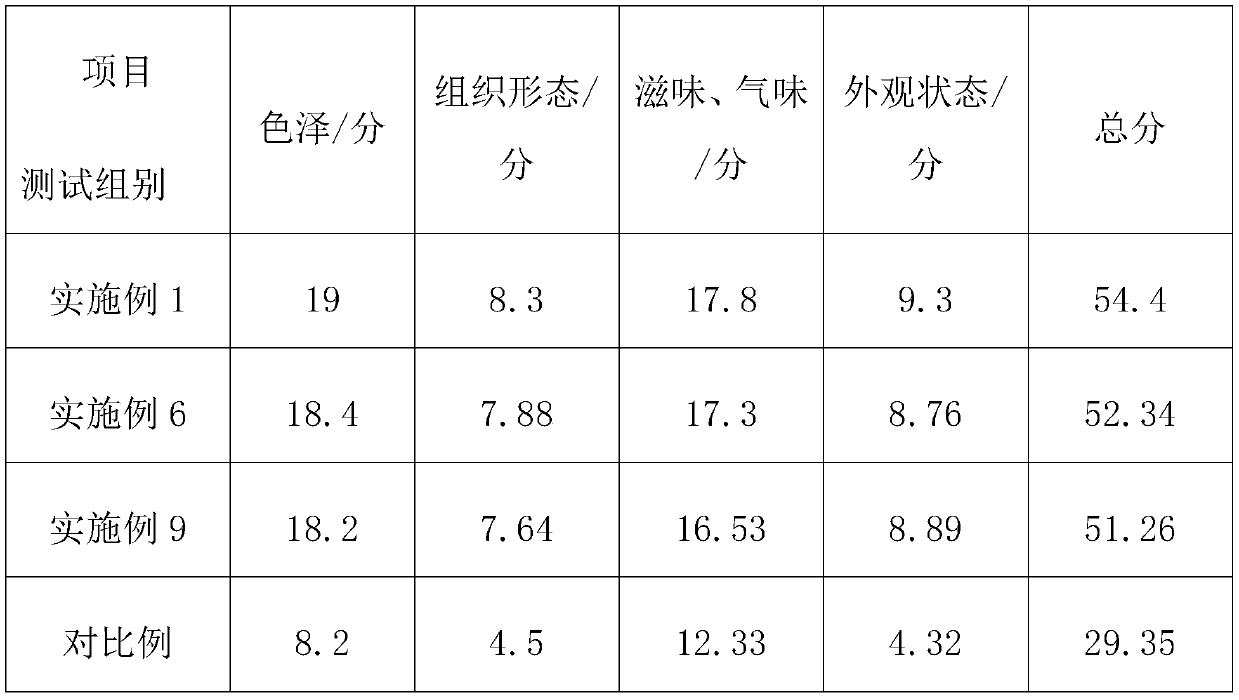

Examples

preparation example Construction

[0029] The embodiment of the present invention also proposes a method for preparing the above-mentioned probiotic solid beverage. It includes:

[0030] Take out the refrigerated probiotic strains, and refrigerate can well protect the activity of the probiotics and avoid the inactivation of the probiotics, thereby affecting the gastrointestinal conditioning effect of the probiotic solid beverage. Dry to 19-21°C in a sterile environment, and 19-21°C in a sterile environment. The sterile environment can prevent probiotics from being contaminated by the external environment, and avoid affecting the quality and quality of probiotic solid beverages. The temperature of 19-21℃ can make the probiotics better mix and fuse with other raw materials, so that the function of regulating the intestinal flora can be fully exerted. The particle size of water-soluble dietary fiber, fructooligosaccharide and galactooligosaccharide can be screened through 40-80 mesh sieve respectively, so as to avoi...

Embodiment 1

[0035] This embodiment provides a probiotic solid beverage, which includes the following raw materials:

[0036] Water-soluble dietary fiber 50g; oligofructose 10g; galacto-oligosaccharide 3g; probiotics 0.4g. Among them, polydextrose is selected for water-soluble dietary fiber, 0.2g of Lactobacillus rhamnosus HN001, 0.1g of Bifidobacterium lactis HN019, and 0.1g of Bifidobacterium animalis BB12 are selected for probiotics.

[0037] The preparation method of the probiotic solid beverage is as follows:

[0038] Take out the refrigerated probiotic strains and dry them in a sterile environment to 19℃. Pass the water-soluble dietary fiber, oligofructose, and galactooligosaccharide through a 40-mesh sieve and bake in an oven until the moisture drops to 0.05%. The first mixture is obtained, and the probiotics and the first mixture are mixed for 15 minutes in a clean workshop at a temperature of 20° C. and a relative humidity of 20% RH, and then filled into a breakable bottle for sealing t...

Embodiment 2

[0040] This embodiment provides a probiotic solid beverage, which includes the following raw materials:

[0041] 80g of water-soluble dietary fiber; 20g of oligofructose; 5g of galacto-oligosaccharide; 3g of probiotics. Among them, polydextrose and inulin are selected as water-soluble dietary fiber, and Lactobacillus rhamnosus HN001 0.8g, Bifidobacterium lactis HN019 2g, and Bifidobacterium animalis BB12 0.2g are selected as probiotics.

[0042] The preparation method of the probiotic solid beverage is as follows:

[0043] Take out the refrigerated probiotic strains, air them in a sterile environment to 21℃, pass the water-soluble dietary fiber, oligofructose, and galactooligosaccharide through 80 mesh sieve respectively and bake in an oven until the moisture drops to 0.15% The first mixture is obtained, and the probiotics and the first mixture are mixed for 30 minutes in a clean workshop at a temperature of 25° C. and a relative humidity of 35% RH, and then filled into a breakable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com