Liquid crystal-based adjustable band-stop miniaturized frequency selective surface

A frequency selective surface, band-stop technology, applied in electrical components, antennas, etc., can solve the problems of improved equipment integration, insufficient working resonance frequency wavelength, unfavorable band-stop frequency selection surface stability, etc., to achieve good incident angle stability. The effect of stability, good angle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

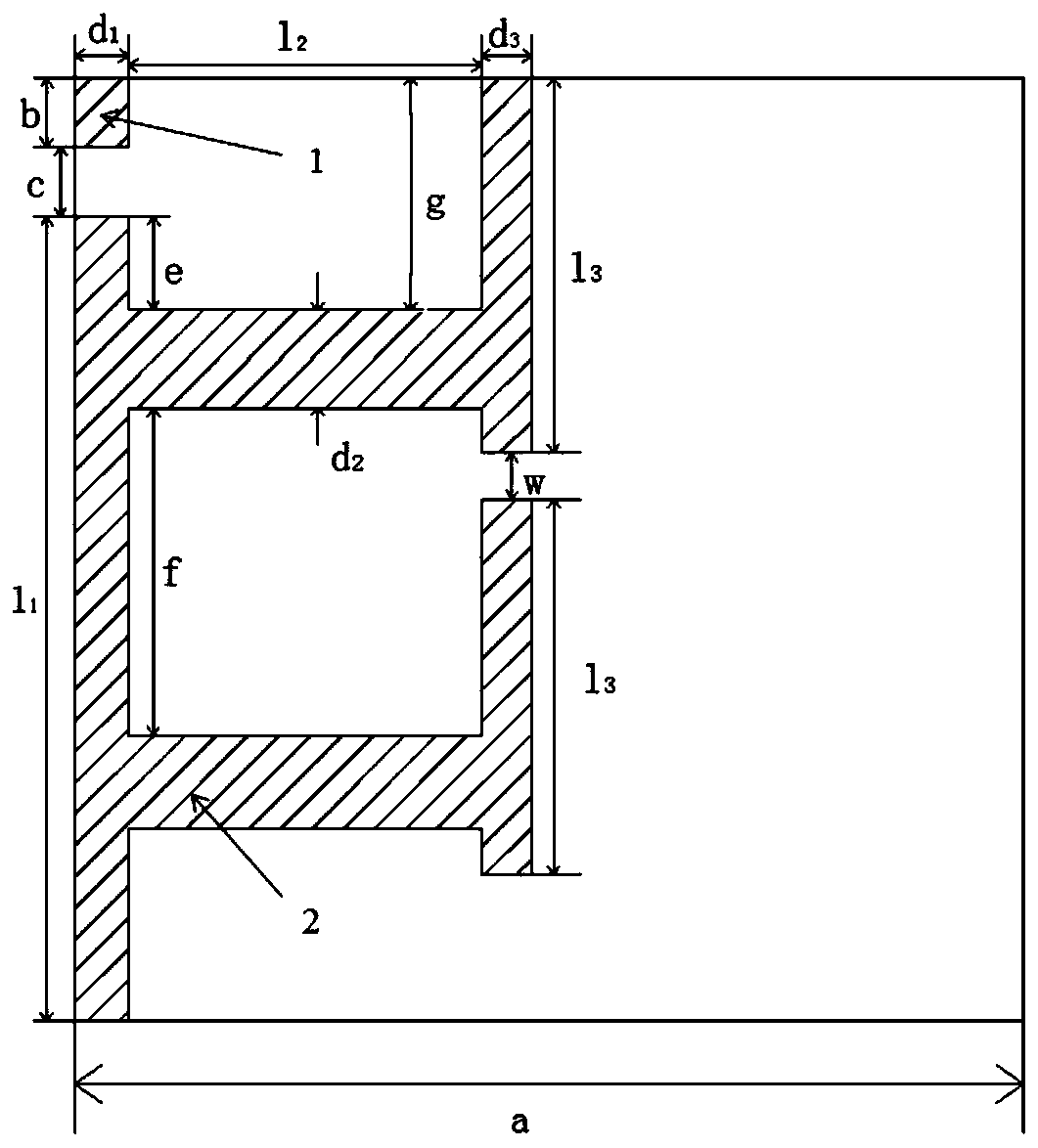

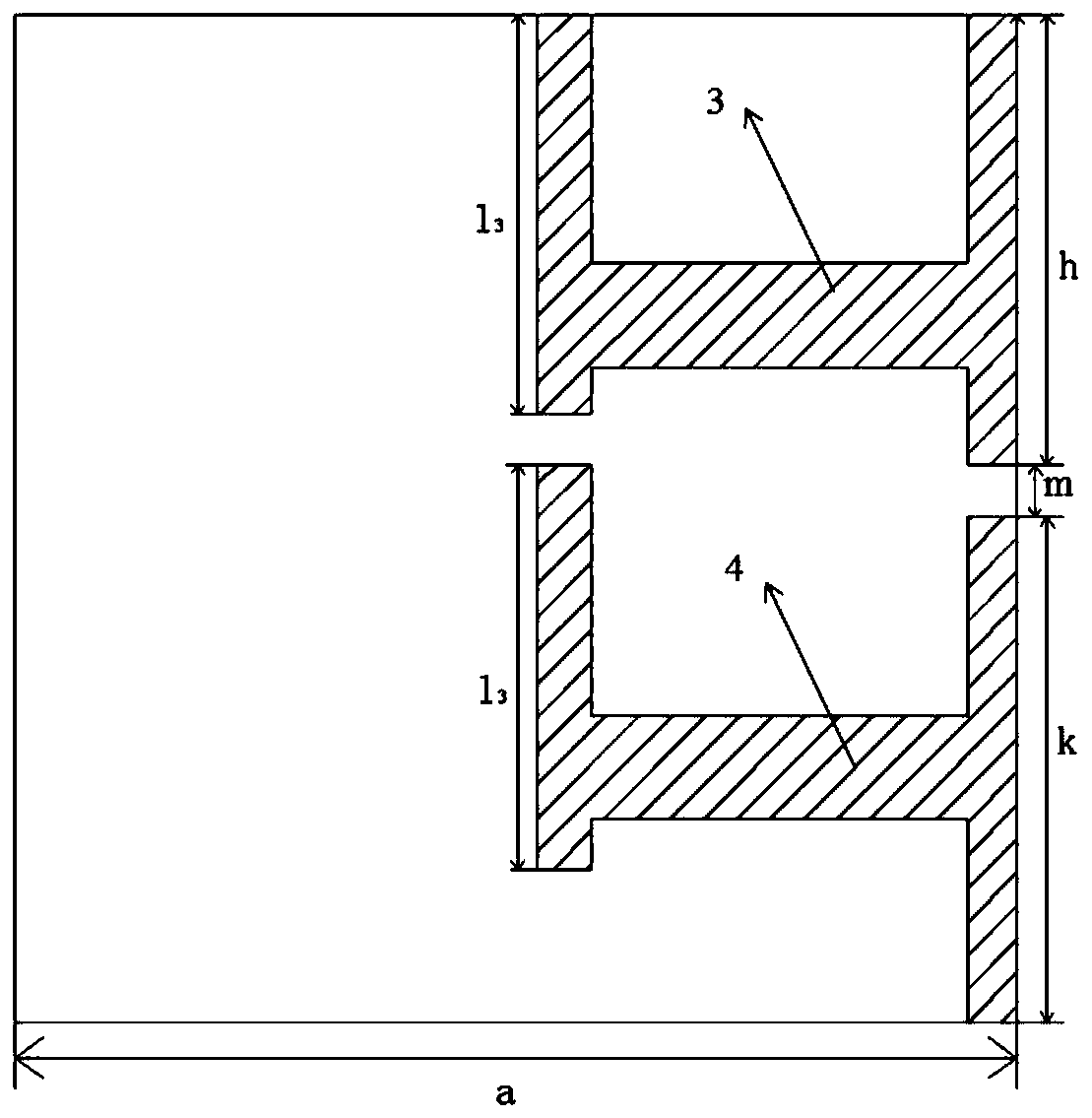

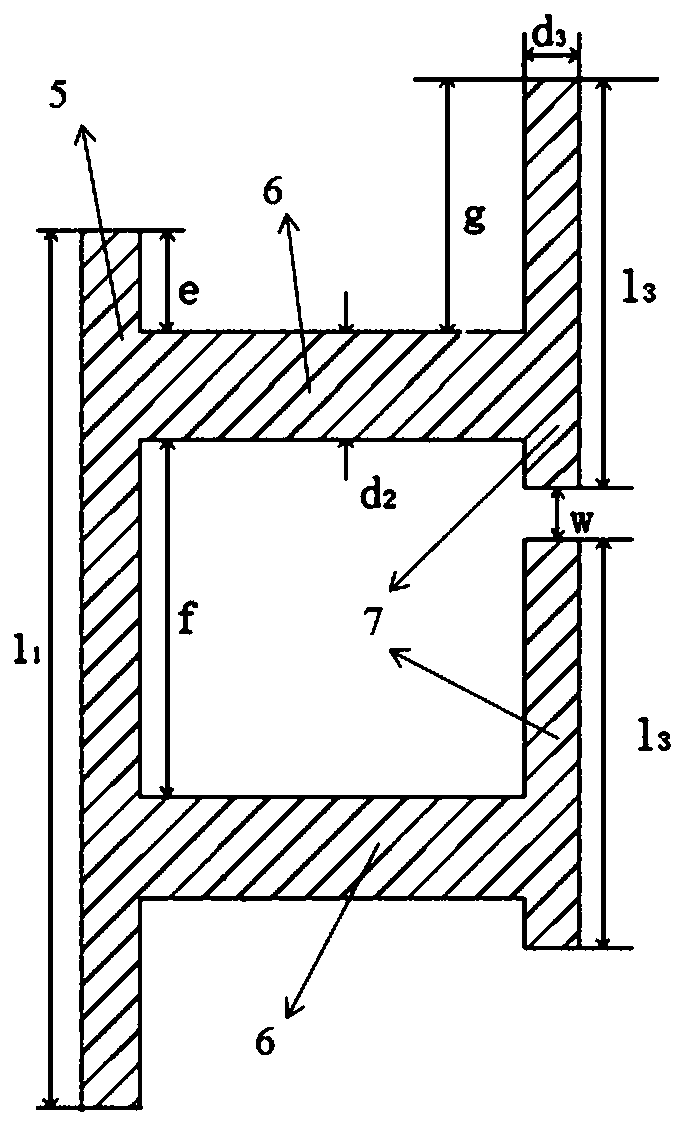

[0031] The selected surface structure of this embodiment is composed of M×N periodically distributed units with a side length of a=2mm, and each unit is sequentially composed of a first dielectric layer, a first metal layer, a second dielectric layer, The second metal layer and the third dielectric layer are laminated. The first dielectric layer, the second dielectric layer and the third dielectric layer are all square structures with a side length of 2 mm. The thickness of the first dielectric layer and the third dielectric layer is 0.1 The relative permittivity ε of mm 1 =4.3, FR-4 material with relative magnetic permeability μ=1. The second dielectric layer is a GT3-23001 liquid crystal material with a thickness of 0.15 mm, a relative permittivity of ε (ε can be adjusted between 2.5 and 3.3), a relative permeability of μ = 1, and an electrical loss tangent of tan δ = 0.0143 .

[0032] Such as Figure 1 to Figure 5 As shown, the first metal layer includes structure I1 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com