Copper wire production line for detecting and pickling surface grease

A production line, copper wire technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problem of pickling liquid loss and other problems, and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

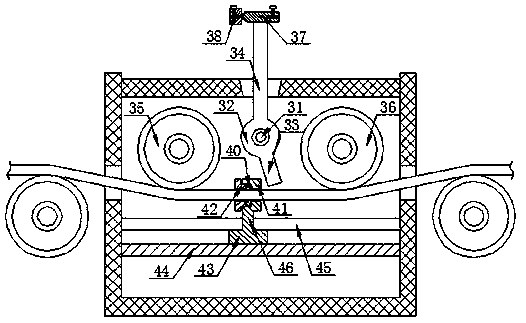

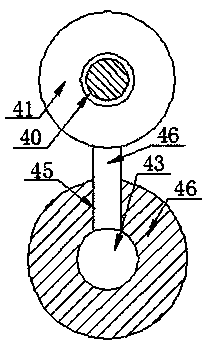

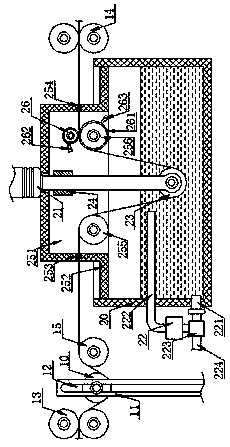

[0016] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as Figure 1 to Figure 3 As shown, a copper wire production line for detecting and pickling surface grease includes a grease detection mechanism and a lifting pickling mechanism arranged downstream of the grease detection mechanism; the grease detection mechanism includes upstream positioning rollers 35, downstream positioning The roller 36, the friction detection ring 40 set on the copper wire between the upstream positioning roller 35 and the downstream positioning roller 36, and the grease detection pendulum above the friction detection ring 40, The grease detection pendulum includes a pendulum installation shaft 31 with a fixed position, a pendulum installation sleeve 32 set on the pendulum installation shaft 31, and a pendulum detection part 33 fixedly connected to the bottom of the pendulum installation slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com