Sodium humate detection method and equipment

A technology of sodium humate and detection equipment, which is applied in the field of detection, can solve the problems of no detection of sodium humate content, etc., and achieve the effects of convenient heating and cooling, convenient operation, and convenient centralized use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of sodium humate detection method, this method comprises the following steps:

[0044] Step 1: Determination of humic acid content

[0045] a1. Weigh 10 g of the sample, put it into a mortar and grind it, pass through a 100-mesh sieve, put 0.2 g of the sieved sample into the first 250 mL beaker, and add 70 mL of distilled water to the first beaker;

[0046] a2. Place the first beaker in a boiling water bath for extraction for 30 minutes. After the extraction is completed, take out the first beaker and place it on the test bench. After cooling to room temperature, transfer the extract in the first beaker to a 100mL volumetric flask. Accurately measure 5mL of distilled water into the first beaker with a pipette gun, wash the first beaker, and repeatedly wash the first beaker three times, transfer the washing liquid into the volumetric flask, and then use distilled water to make the volume of the liquid in the volumetric flask to the scale line;

[0047] a3. Filter...

Embodiment 2

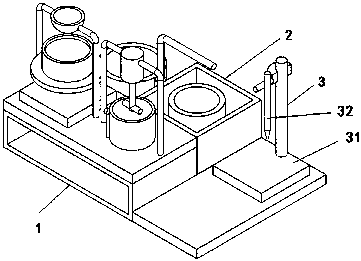

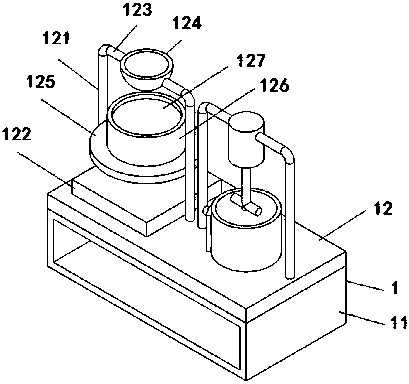

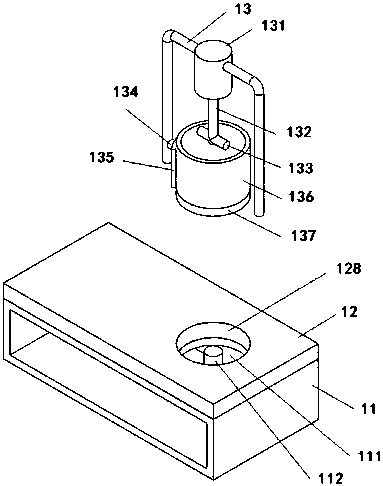

[0063] Such as Figure 1 to Figure 4 A sodium humate detection device shown includes a sample preparation mechanism 1 and a heating and cooling mechanism 2 fixedly connected from front to back, and a titration mechanism 3 is fixedly installed on the right side of the heating and cooling mechanism 2;

[0064] The sample preparation mechanism 1 includes a storage box 11 and a support base 12 fixedly installed on the top surface of the storage box 11;

[0065] The left end of the top surface of the support base plate 12 is fixedly installed with two relatively symmetrical first connecting rods 121, and a weighing device 122 is arranged between the two first connecting rods 121, and the weighing device 122 is placed on the top surface of the supporting base plate 12. A second connecting rod 123 is installed vertically on the end of the connecting rod 121 away from the support base plate 12, and a mortar 124 is installed on the right side of the second connecting rod 123 to rotate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com