How a freeze drying system with secondary anti-icing protection works

A drying system and working method technology, applied in the direction of separation methods, drying solid materials, chemical instruments and methods, etc., can solve the problems of affecting the normal operation of the system, wasting compressed air, and low accuracy, and solve the problems of insufficient system output capacity, Prevent ice blockage and waste of electric energy, solve the effect of non-adjustable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the accompanying drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. The purpose of providing these embodiments is to make the disclosure of the present invention more thorough and comprehensive.

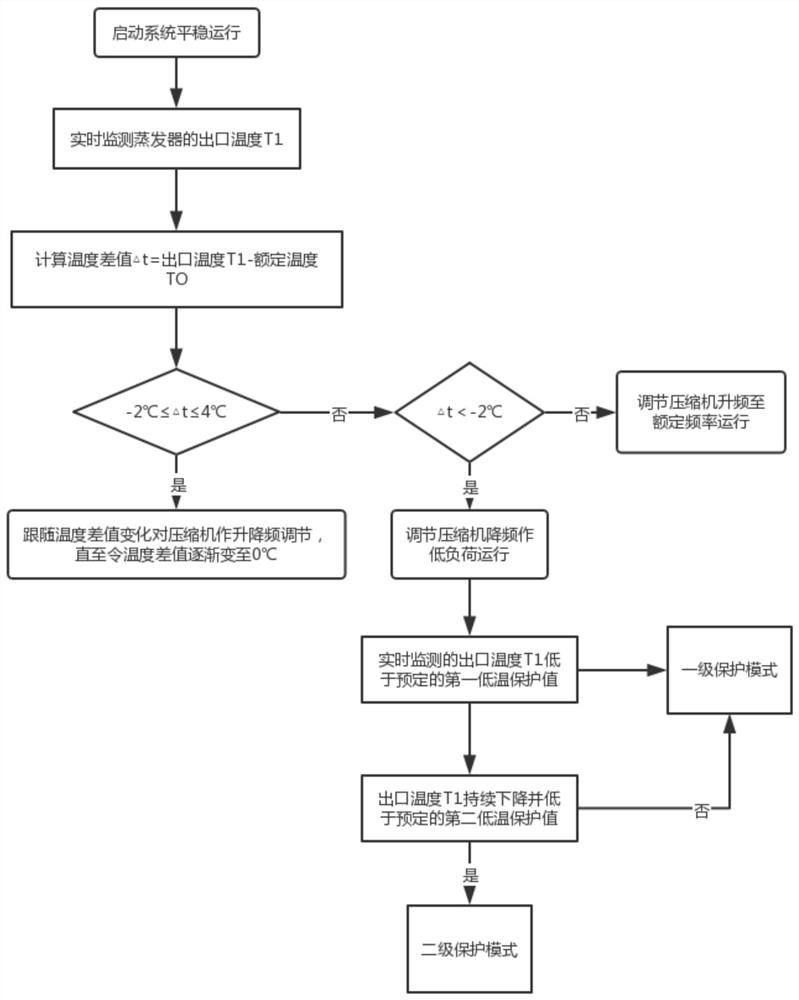

[0016] See attached figure 1 As shown, the working method of the refrigerated drying system with secondary anti-icing protection, the refrigerated drying system of this embodiment includes a compressor (DC frequency conversion), a condenser and an evaporator, wherein the two ends of the condenser are respectively connected to The inlet of the evaporator is connected to the exhaust end of the compressor, and the outlet of the evaporator is connected to the return air end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com