Air compressor

An air compressor and body technology, applied in the field of air compressors, can solve the problems of complicated oil circuit of the reversing valve, high cost, pressure pulsation, etc., to avoid electrical instability factors, save space and parts, and have a long working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

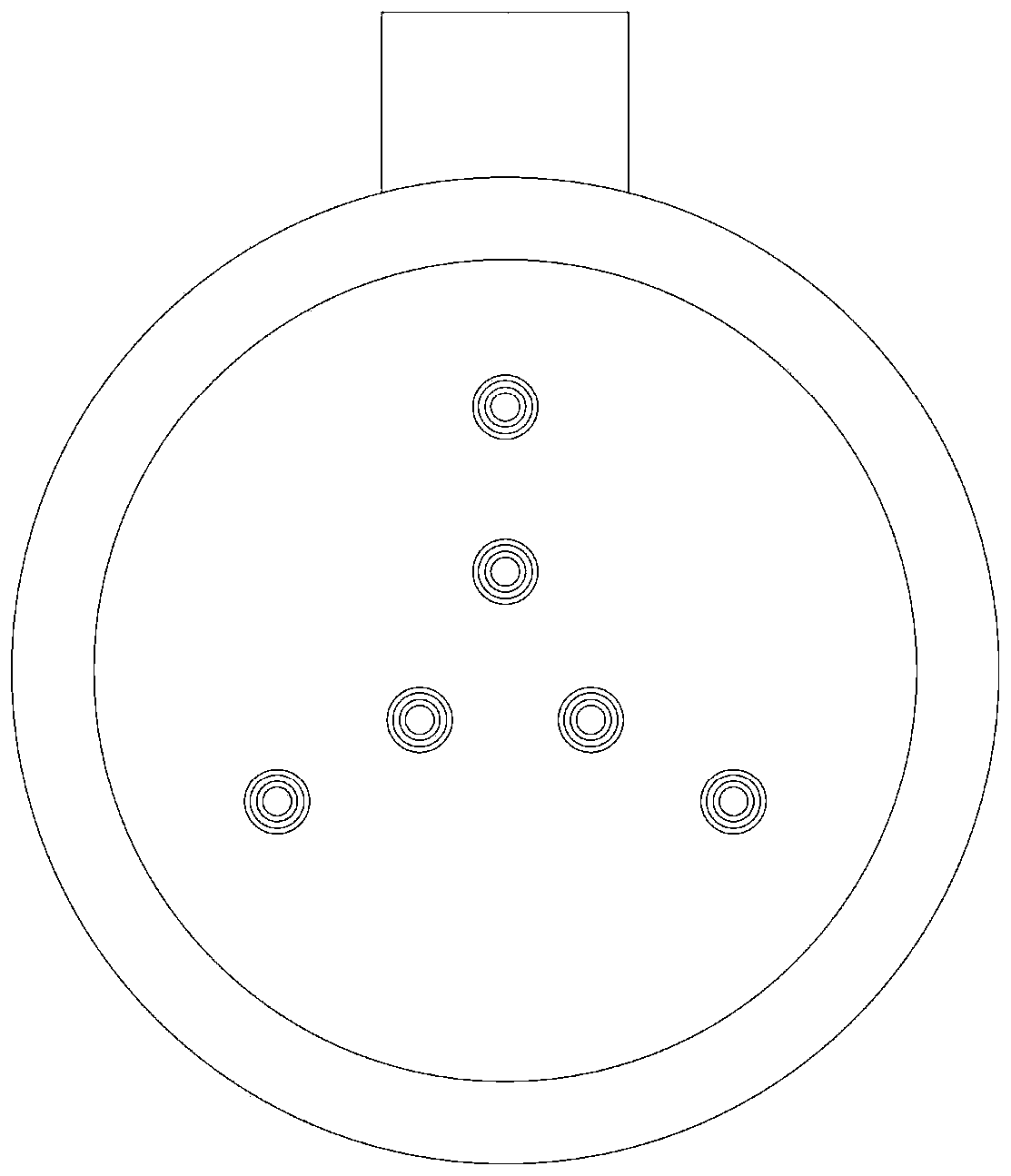

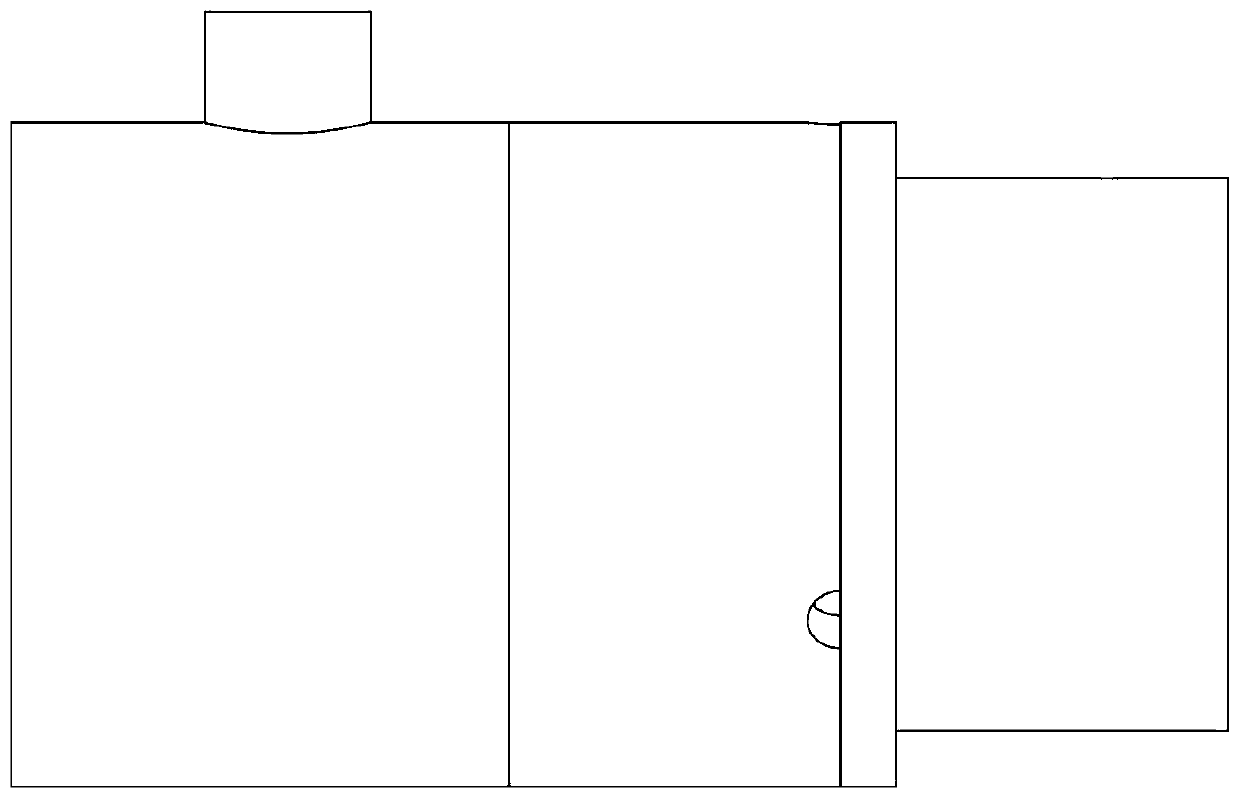

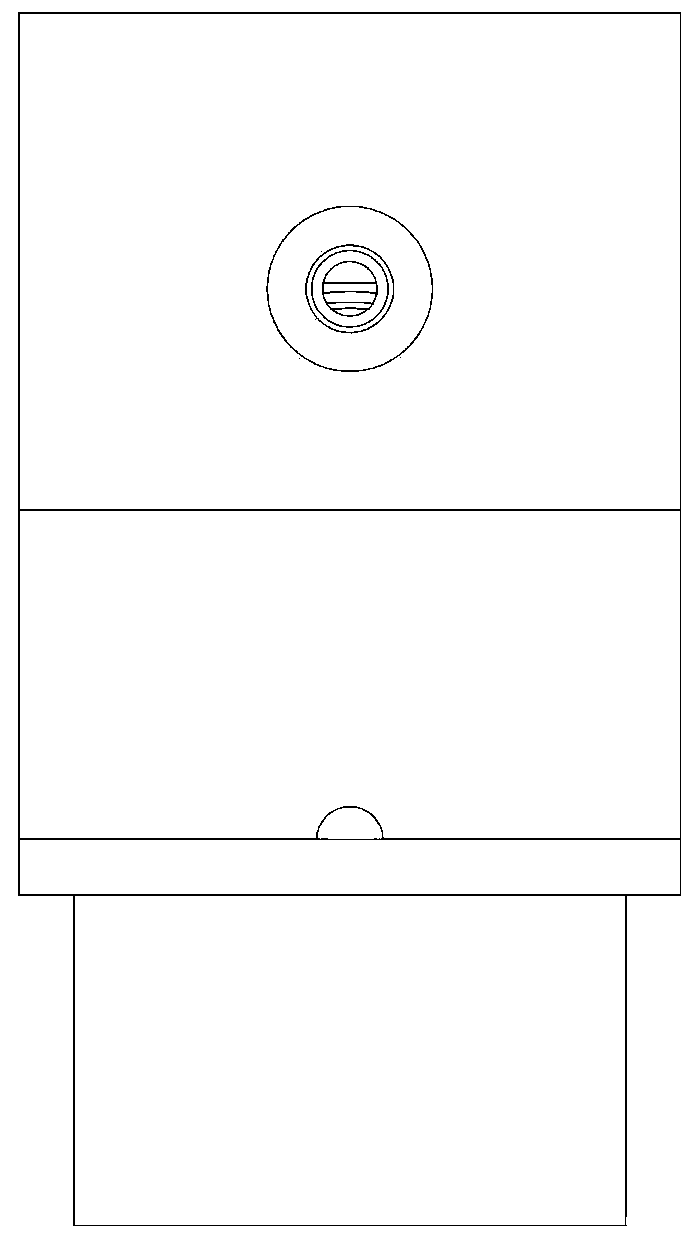

[0025] see Figure 1-13 As shown, an air compressor includes a body 1, and the first axial hole, the second axial hole, and the third axial hole opened at the left end are evenly arranged in the body 1 along the circumferential direction, and the body 1 The left end cover 6 is fixedly installed on the left side of 1, and the right casing 2 is fixedly installed on the right side; a right chamber 2a is formed between the body 1 and the right casing 2; a first piston is slidably connected in the first axial hole body 5a, the second piston body 5b is slidably connected in the second axial hole, and the third piston body 5c is slidably connected in the third axial hole; the right side of the first piston body 5a is extended with a The first piston rod 511 in 2a, the right side of the second piston body 5b are all extended with the second piston rod 512 that stretches into the right chamber 2a, the right side of the third piston body 5c is all extended with the second piston rod 512...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com