Mildew-proof anti-cracking light wall material, preparation method and application thereof

A lightweight wall, anti-mold technology, applied in building materials, building components, buildings and other directions, can solve the problems of large land resource consumption, slow construction speed, overweight wall and other problems, achieve low cost, low alkalinity, inhibit The effect of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

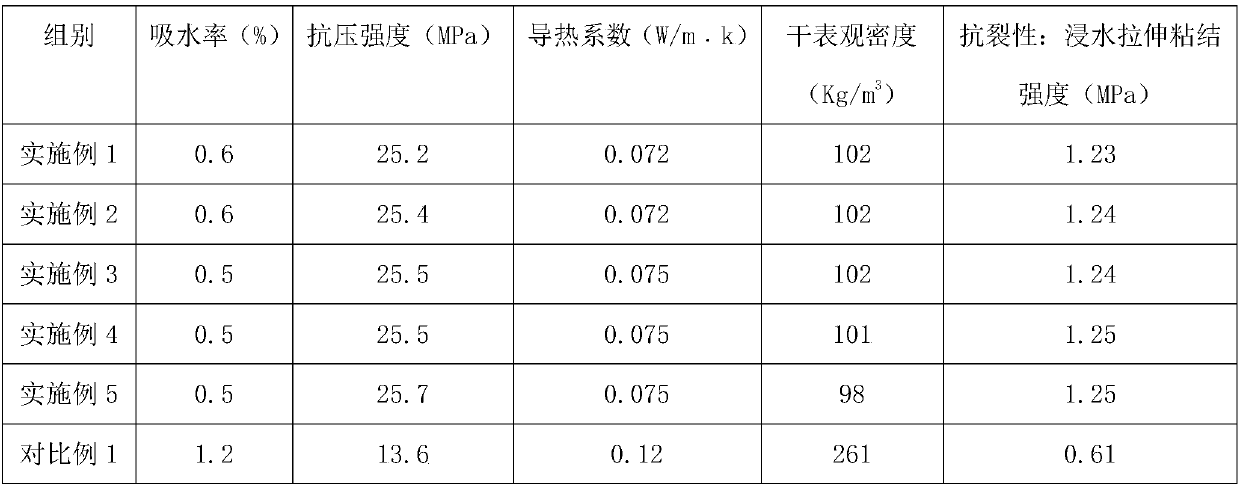

Examples

Embodiment 1

[0025] Composition of raw materials (parts by weight): 70 parts of expanded polystyrene, 30 parts of glass fiber reinforced cement, 20 parts of diatom mud, 15 parts of fly ash, 10 parts of yellow sand, 10 parts of caustic soda, 5 parts of shale, charcoal 2 parts of black, 1 part of modified melamine water reducer, 2 parts of sodium stearate, 1 part of polystyrene, 1 part of FC-5 and 30 parts of water.

[0026] A method for preparing a mildew-resistant and crack-resistant lightweight wall material, which is prepared according to the following method: weighed expanded polystyrene, glass fiber reinforced cement, diatom mud, caustic soda, carbon black, fly ash, Mix yellow sand and shale, dry mix and evenly form a mixture, divide 50% of the weighed polystyrene into the mixture and stir evenly, pour the remaining polystyrene into 1 / 2 of the water to dissolve, and dissolve the dissolved Pour the solution into the dry mix and stir thoroughly to obtain a slurry; then add the weighed mo...

Embodiment 2

[0029] Composition of raw materials (parts by weight): 100 parts of expanded polystyrene, 50 parts of glass fiber reinforced cement, 30 parts of diatom mud, 30 parts of fly ash, 20 parts of yellow sand, 15 parts of caustic soda, 15 parts of shale, charcoal 7 parts of black, 5 parts of aliphatic water reducer, 6 parts of sodium alkyl glyceryl ether sulfonate, 4 parts of carboxymethyl cellulose, 3 parts of DPT-5 and 50 parts of water.

[0030] A method for preparing a mildew-resistant and crack-resistant lightweight wall material, which is prepared according to the following method: weighed expanded polystyrene, glass fiber reinforced cement, diatom mud, caustic soda, carbon black, fly ash, Mix yellow sand and shale, dry mix to form a mixture, divide 50% of the weighed carboxymethyl cellulose into the mixture and stir evenly, pour the remaining carboxymethyl cellulose into 1 / 2 of the water to dissolve , pour the dissolved solution into the dry mix and stir thoroughly to obtain a...

Embodiment 3

[0033] Composition of raw materials (parts by weight): 80 parts of expanded polystyrene, 35 parts of glass fiber reinforced cement, 22 parts of diatom mud, 17 parts of fly ash, 12 parts of yellow sand, 12 parts of caustic soda, 7 parts of shale, charcoal 3 parts of black, 2 parts of casein, 3 parts of sodium petroleum sulfonate, 2 parts of rosin, 1 part of DH-1 and 35 parts of water.

[0034] A method for preparing a mildew-resistant and crack-resistant lightweight wall material, which is prepared according to the following method: weighed expanded polystyrene, glass fiber reinforced cement, diatom mud, caustic soda, carbon black, fly ash, Mix yellow sand and shale, dry mix it evenly to form a mixture, divide 50% of the weighed rosin into the mixture and stir evenly, pour the remaining rosin into 1 / 2 of the water to dissolve, and pour the dissolved solution into Stir fully in the dry mixture to obtain a slurry; then add the weighed casein, sodium petroleum sulfonate and DH-1 int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com