Processing technology of injection shoe with sole having anti-skid and shock absorption functions

A processing technology, technology of injection molding shoes, applied to footwear, household appliances, other household appliances, etc., can solve problems such as difficulty, space occupation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

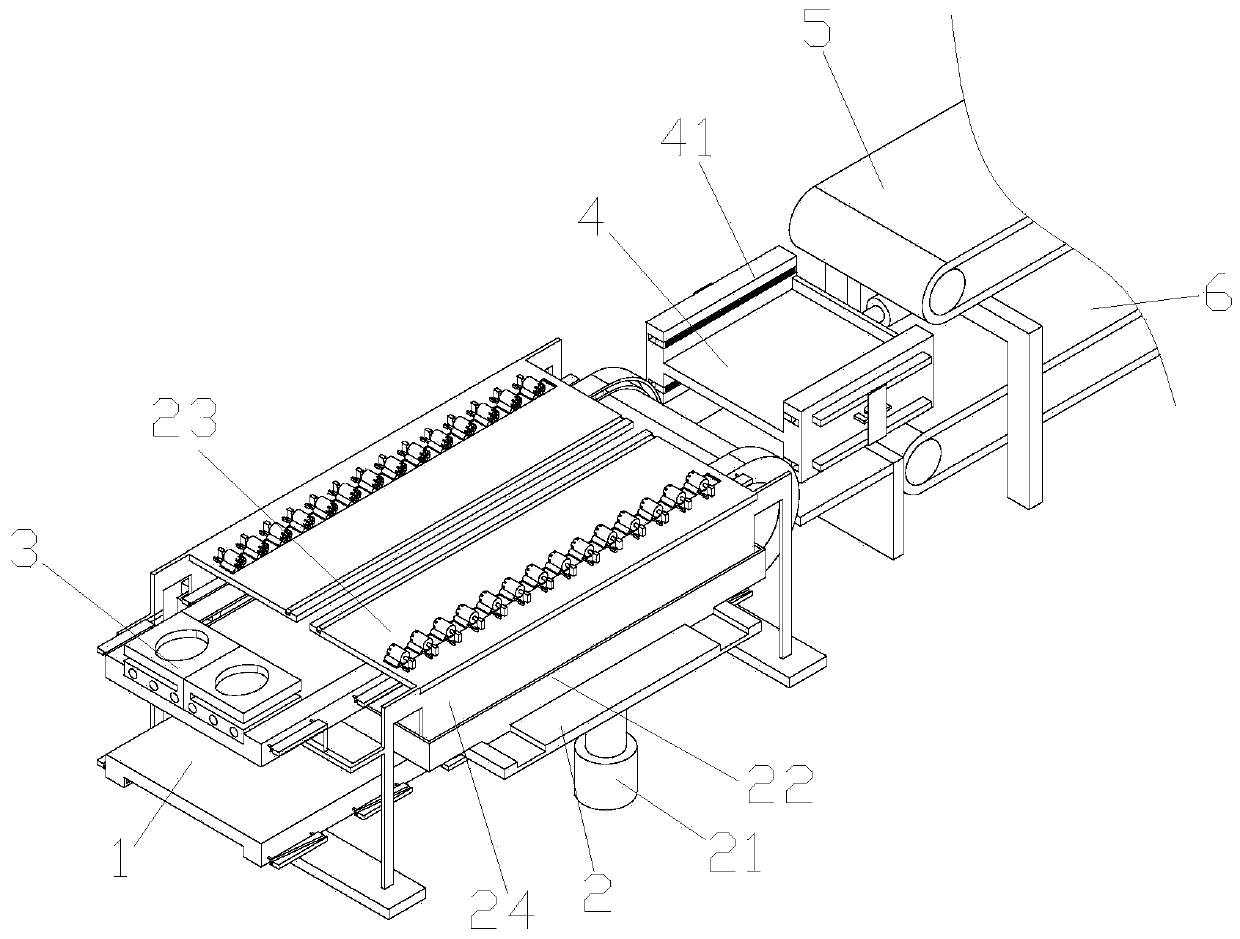

[0038] like Figure 1-19 As shown, a processing technology of injection-molded shoes with anti-slip and shock-absorbing soles, including the following steps: a, making the shoe body part; b, making a shoe mold that matches the shoe body; c, covering the shoe body On the shoe mold; d. After completing the combination of the shoe body and the shoe mold, put the shoe mold into the injection molding machine to complete the injection molding of the sole; e. After completing the injection molding, put the shoe mold to be cooled into the cooling Cooling in the device, after the cooling is completed, the molding process of the shoe body and its sole is completed; the shoe body material includes leather material and cloth; the injection molded shoe also includes a shoe midsole, and the shoe midsole material includes cardboard , leather, and cloth; the auxiliary materials for injection molding shoes include glue, solvent, color masterbatch, buckle, and yarn; the manufacturing process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com