Carrier roller shaft production line device

A technology of production line equipment and idler shafts, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of insufficient cutting precision of workpieces, unsatisfactory working effects and efficiency of mechanisms, and inability to achieve accurate and stable feeding units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

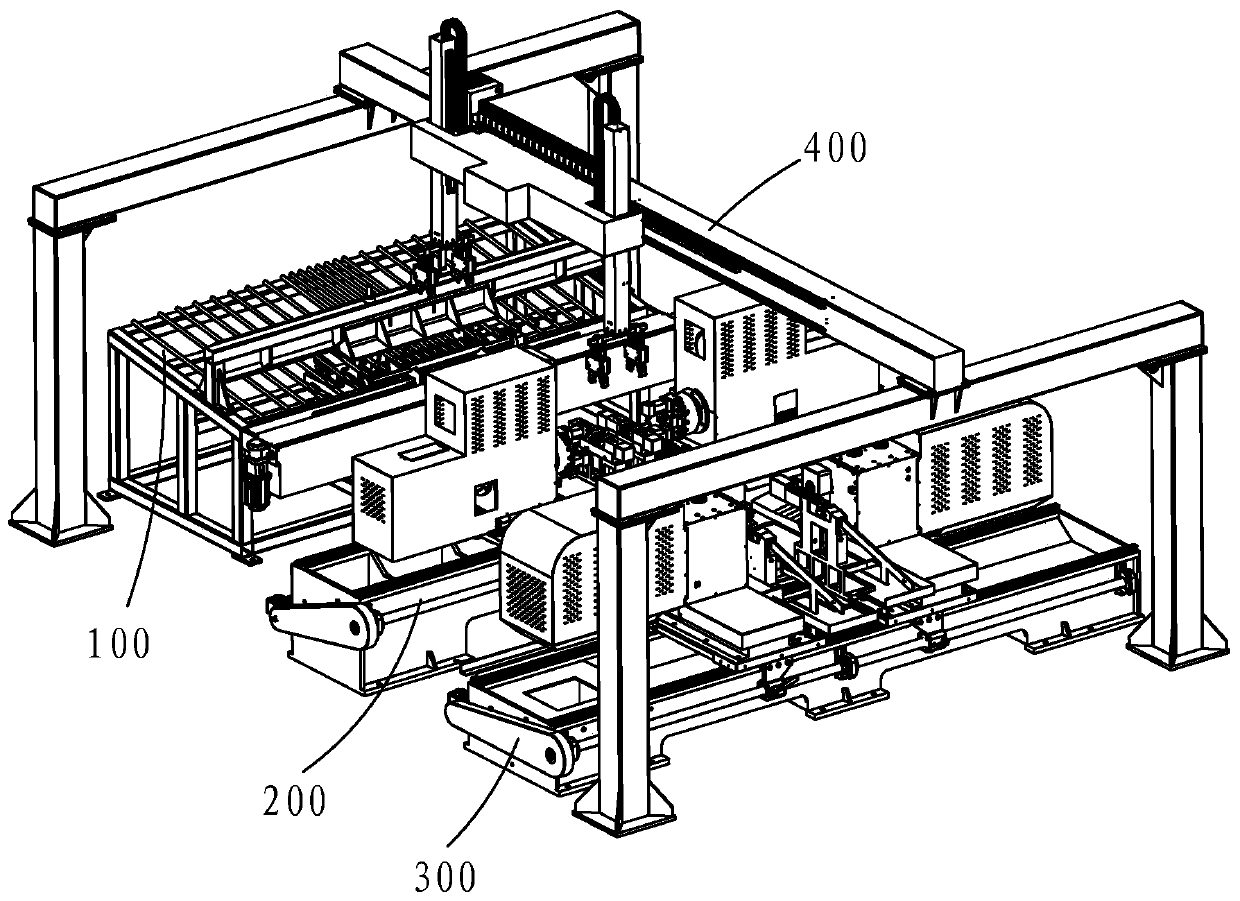

[0087] Such as figure 1 As shown, an idler shaft production line equipment includes an automatic feeding mechanism 100, a machine tool 200 integrated with end face chamfering and center holes of all circlip tankers, a double-head CNC milling and flattening machine 300, an automatic grabbing mechanism 400 and a Control mechanism 500 .

[0088] The control mechanism 500 is respectively connected with the automatic feeding mechanism 100, the machine tool 200 integrated with the end face chamfering of the spring groove car and the center hole punching, the double-head CNC milling and flattening machine 300 and the automatic grabbing mechanism 400.

[0089] The control mechanism 500 controls the automatic feeding mechanism 100 to feed the machine tool 200 integrated with the end face chamfering of the circlip groove car and punches the center hole. The control mechanism 500 controls the automatic material grabbing mechanism 400 to grab downwards and move the workpieces that reach t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com