Reversible rolling mill gap eliminating device

A gap and rolling mill technology, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve problems such as aggravating product quality instability, decreasing equipment function accuracy, impact load, etc., to reduce the number, The effect of stabilizing the work roll system and eliminating the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

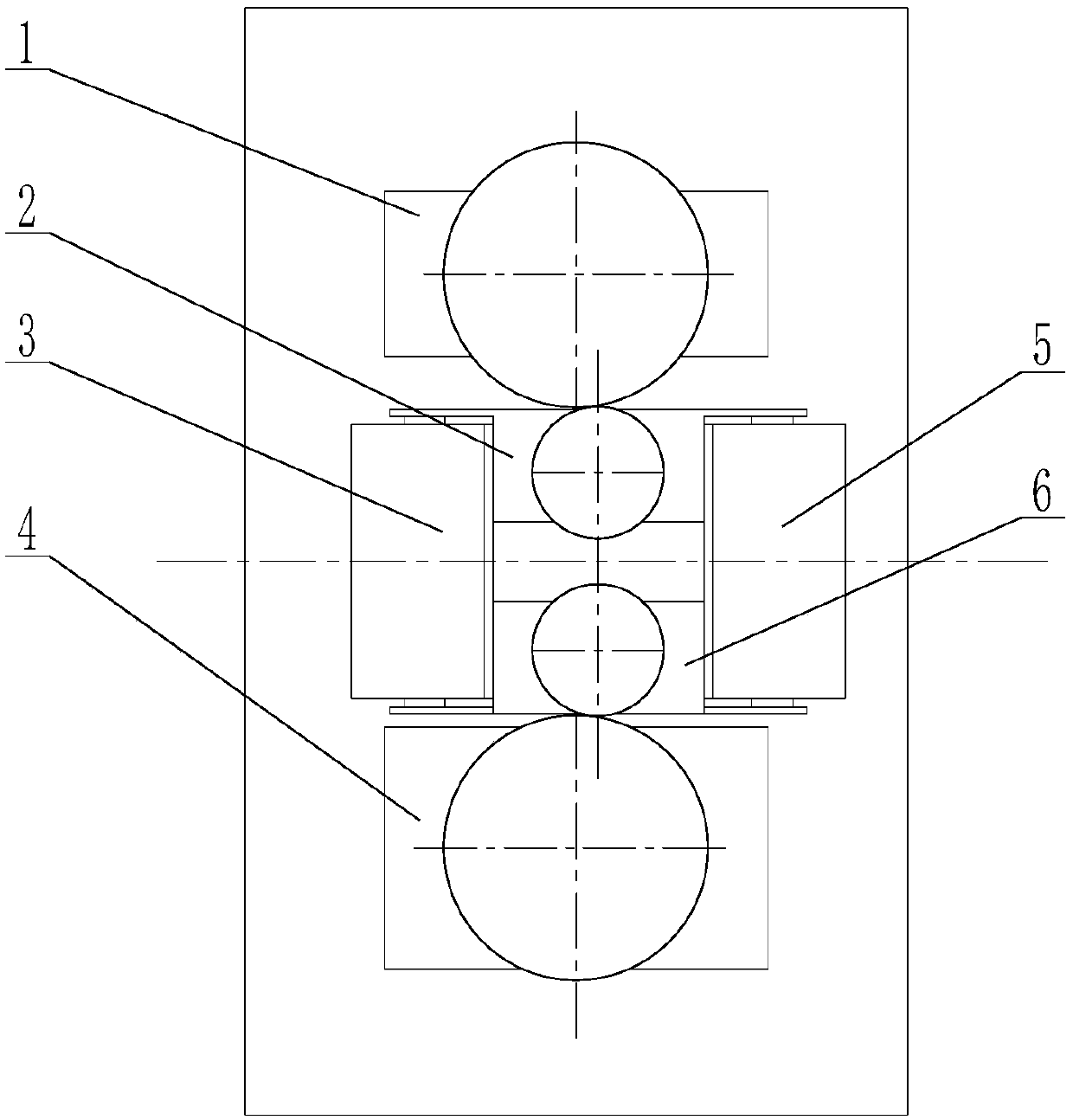

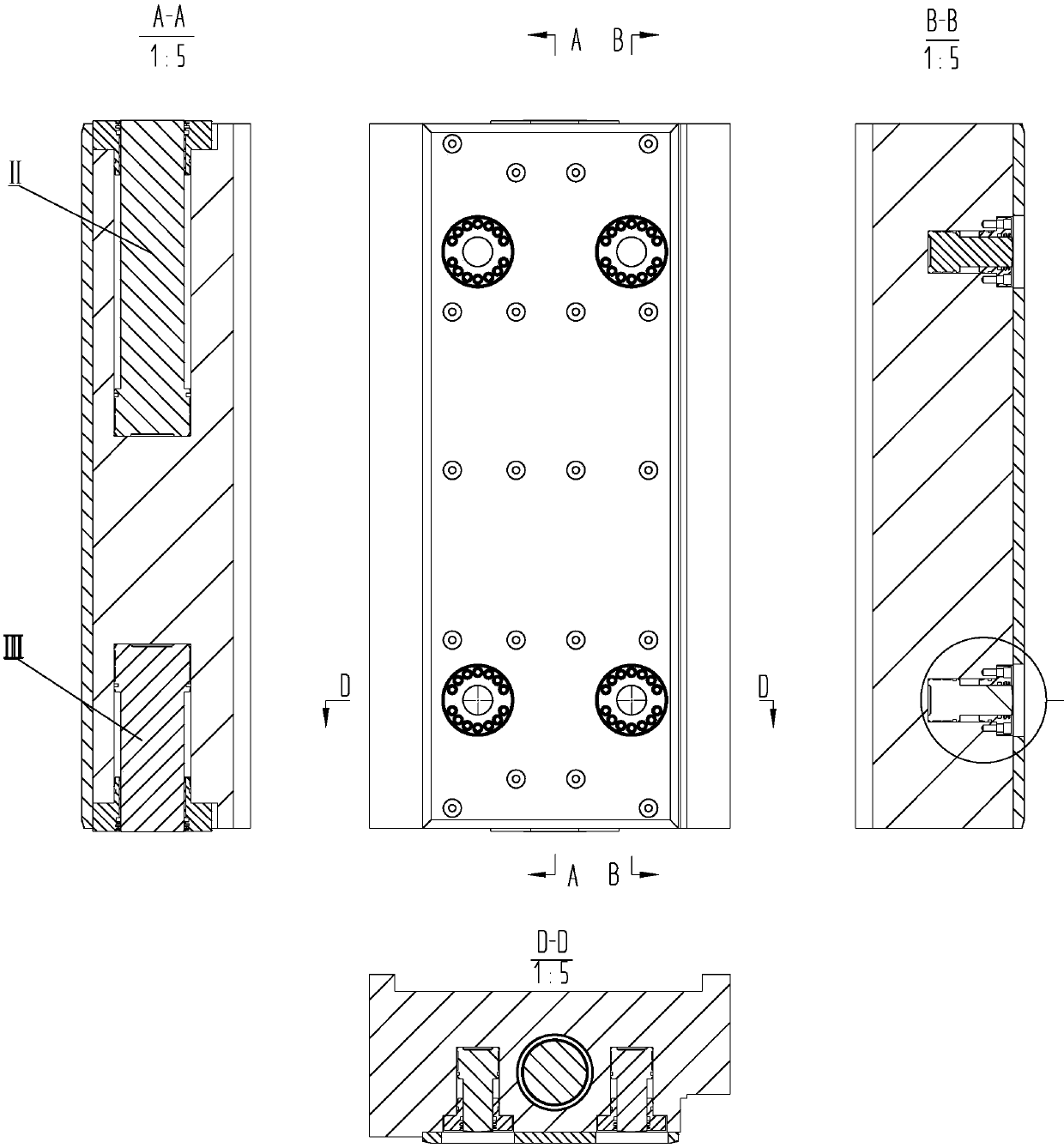

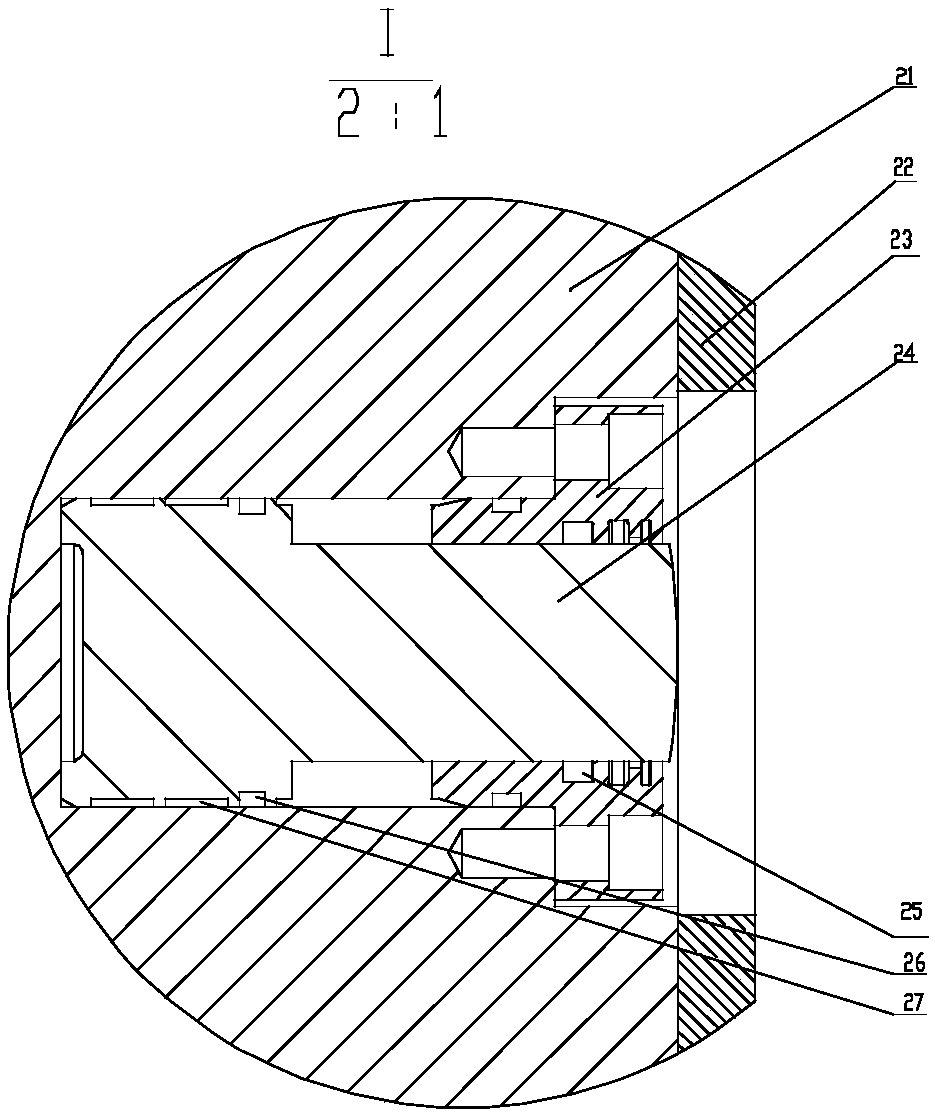

[0020] Embodiment 1: refer to figure 1, a rolling mill gap elimination device, the elimination device includes an upper support roll 1, an upper work roll 2, an inlet balance cylinder block 3, an outlet balance cylinder block 5, a lower work roll 6, a lower support roll 4, and a hydraulic control system, In the figure, the inlet balance cylinder block 3 and the outlet balance cylinder block 5 are installed in the archway frame of the rolling mill. There is a horizontal eccentricity between the center line of the work roll 2 and the center line of the backup roll 1. During operation, under the action of the pressing force , the work roll 2 is close to the outlet balance cylinder block 5, so the outlet balance cylinder block does not need to design a horizontal oil cylinder. The inlet balancing cylinder block includes a cylinder block body 21, a lining plate 22, a cylinder end cover 23, a piston rod 24, an end cover sealing assembly 25, a piston sealing assembly 26 and a guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com