An automatic spraying machine

A technology of automatic spraying and spraying mechanism, applied in the direction of spraying device, etc., can solve the problems of spraying area adjustment, large limitations, waste of spraying raw materials, etc., achieve the effect of stable transmission, high degree of automation, and avoid uneven spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

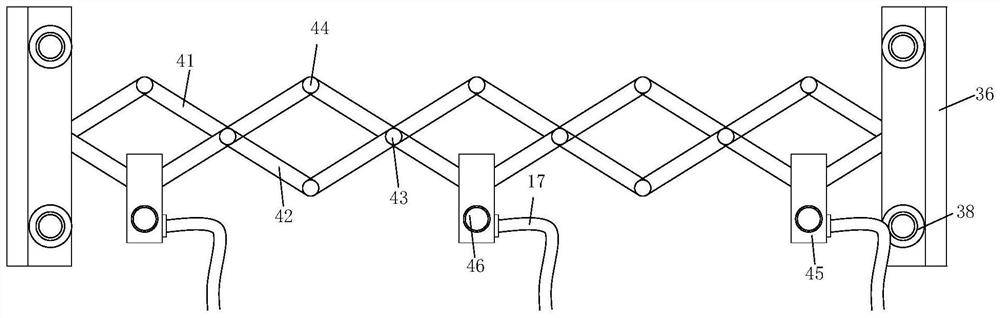

[0023] like Figure 1 - Figure 5 As shown, an automatic sprayer according to the present invention includes an apparatus frame 1, a transport mechanism 2, a guide mechanism 3, and a spray mechanism 4, and a transport mechanism 2, a guide mechanism 3, and a spraying mechanism 4 on the device frame 1. The transport mechanism 2 and the guiding mechanism 3 are displaced, the spray mechanism 4 is mounted on the guide mechanism 3, the transport mechanism 2, the carrier operation, the guide mechanism 3 drives the spraying mechanism 4 to change the spray area, the device frame 1 including The frame 11, the casing 12, the casing 13, the tube 14, the flange 15, the branch pipe 16, the rubber hose 17 and the tube opening 18, the lower side of the frame 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com