Coal pulping system waste gas purification device and coal pulping system waste gas purification process

An exhaust gas purification device and exhaust gas purification technology are applied in the direction of air quality improvement, chemical instruments and methods, and separation methods, which can solve the problems of long process flow and large floor area, so as to improve the absorption efficiency and reduce the generation of waste liquid , Processing efficiency and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

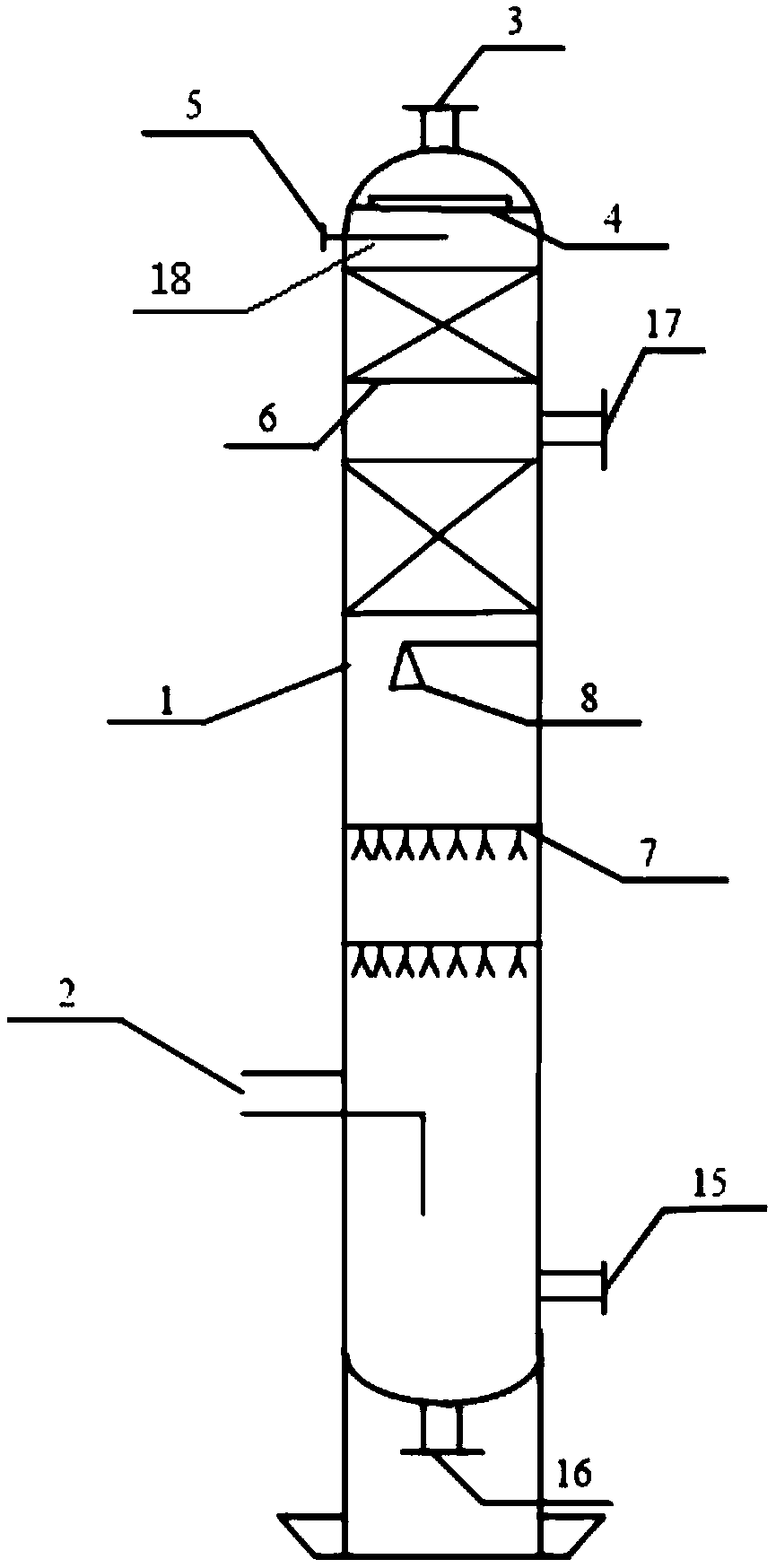

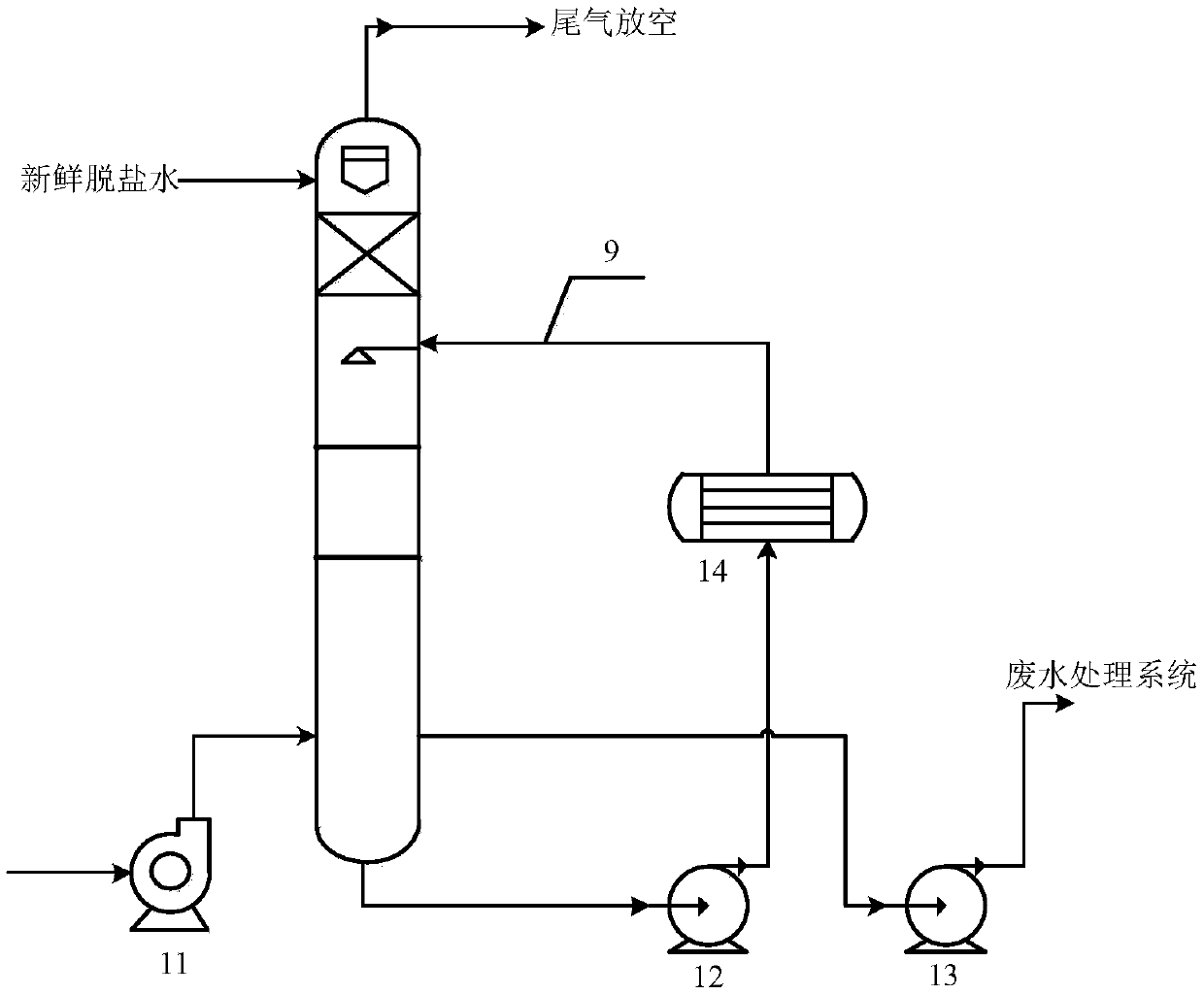

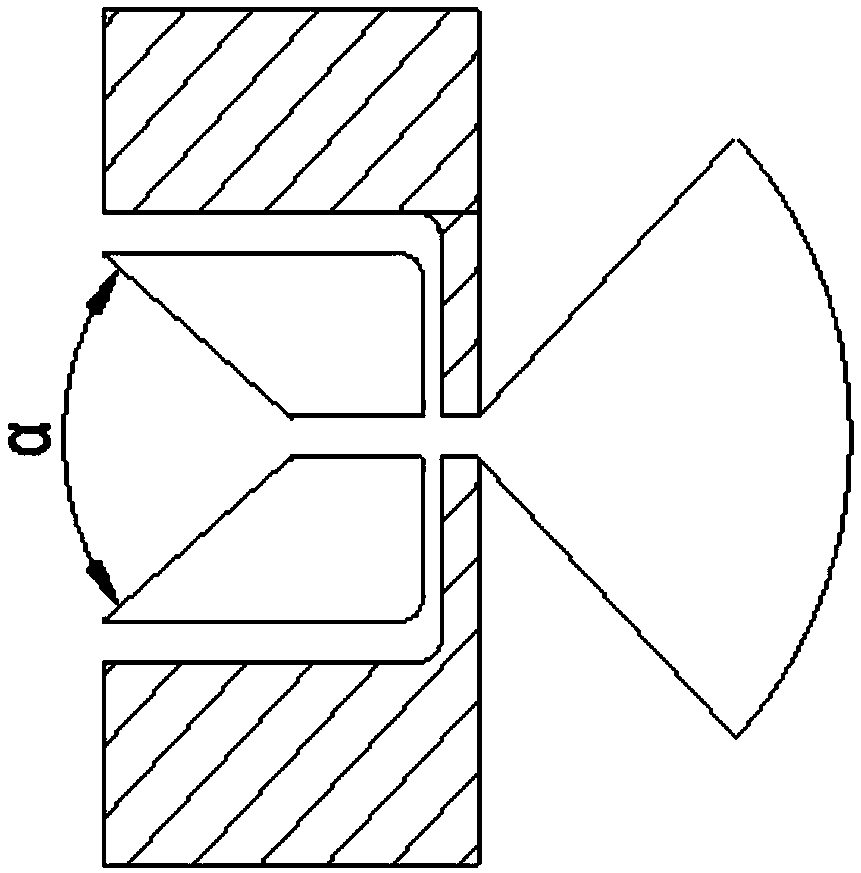

[0057] Such as figure 1 As shown, the exhaust gas purification tower 1 of this embodiment includes a tower body, an air inlet 2 is arranged at the bottom of the tower body, an air outlet 3 and a wire mesh demister 4 are arranged at the top, a fresh absorption liquid inlet 5, and a trough distributor 18 . Two packing support screens 6 are arranged inside the tower body, and fillers are placed on the packing support screens 6 to form a packing layer, and nozzles (circulating liquid spray nozzles) are arranged between the fresh absorption liquid absorption section and the circulating liquid absorption section. device) 8; a plurality of gas-liquid flow uniform distribution devices 7 are set between the circulating liquid spray nozzle device (nozzle 8) and the exhaust gas inlet (air inlet 2) in the circulation absorption section; the nozzle 8 passes through the acid and alkali resistant pipeline 9 and the circulating water pump 12 are connected to each other (the packing is not dra...

Embodiment 2

[0065] Such as figure 1 As shown, the exhaust gas purification tower 1 of this embodiment includes a tower body, an air inlet 2 is arranged at the bottom of the tower body, an air outlet 3 and a wire mesh demister 4 are arranged at the top, a fresh absorption liquid inlet 5, and a trough distributor 18 . There are two packing support screens 6 inside the tower body, and fillers are placed on the packing support screens 6 to form a packing layer; high-efficiency conical nozzles (circulating fluid nozzles) 8 are arranged between the packing layers, and the conical nozzles 8 pass through the resistant The acid-base pipeline 9 and the circulating water pump 12 are connected to the liquid in the bottom of the tower (the packing is not shown in the figure).

[0066] The exhaust gas purification tower is equipped with a centrifugal pumping machine 11, which can be adjusted by frequency conversion to realize energy saving while ensuring the pumping effect. A circulating water pump 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com