Stator apparatus with wiring end disc for an electric motor, and use of the stator apparatus

A technology for motors and stators, applied in electromechanical devices, electric components, electrical components, etc., can solve the problems of troublesome stator unit assembly, limited construction space of contact parts, etc., achieve simple and reliable manufacturability, improve manufacturing quality, and high flexibility degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

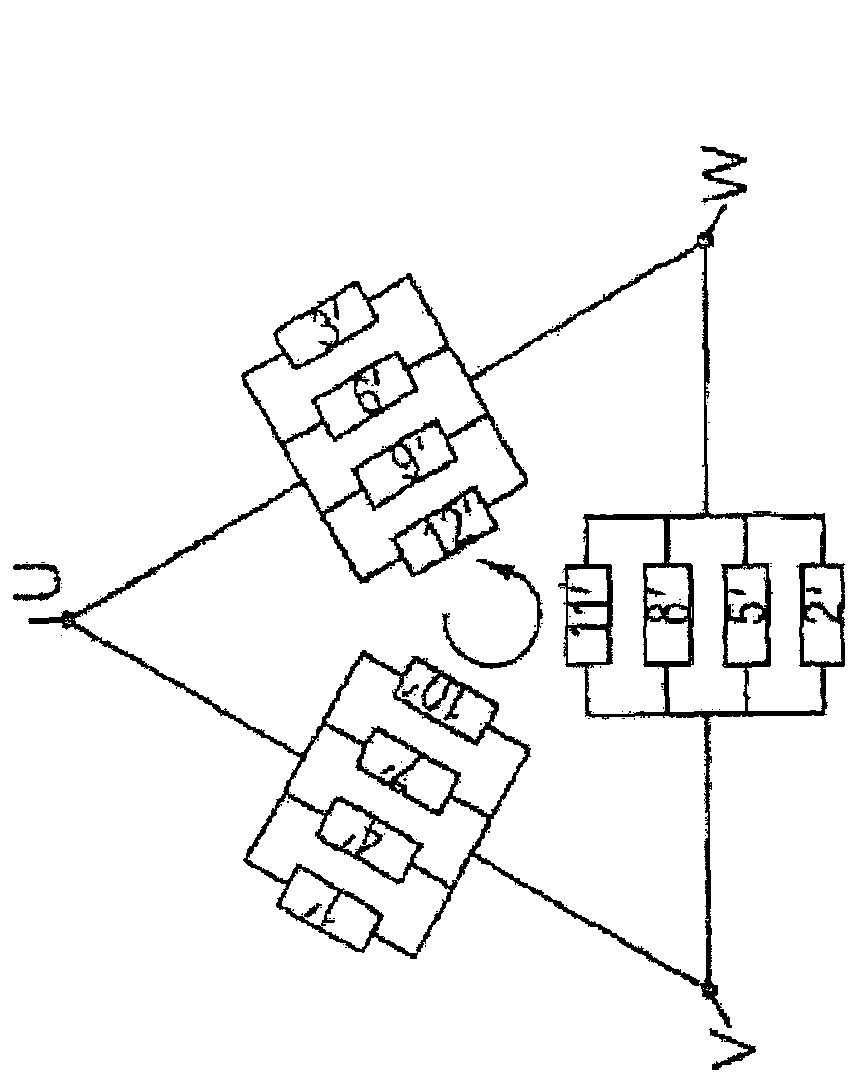

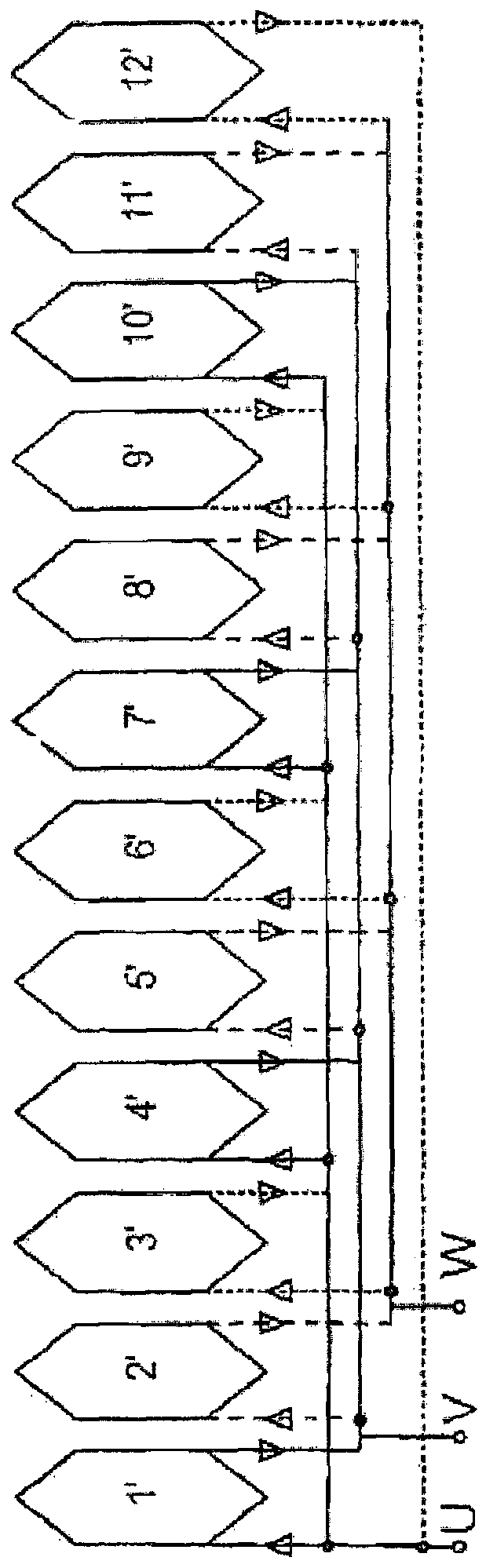

[0037] according to figure 1 and figure 2 As shown in the circuit diagram in , windings 1' to 12' are applied with a three-phase rotating field with phases (terminal polarities) U, V, W, where figure 1 or figure 2 In the manner shown, every four parallel windings of the windings 1' to 12' form a branch of the triangular line shown in the figure, and along the winding carrier 4 ( image 3 ) are nested in the circumferential direction according to their numbers.

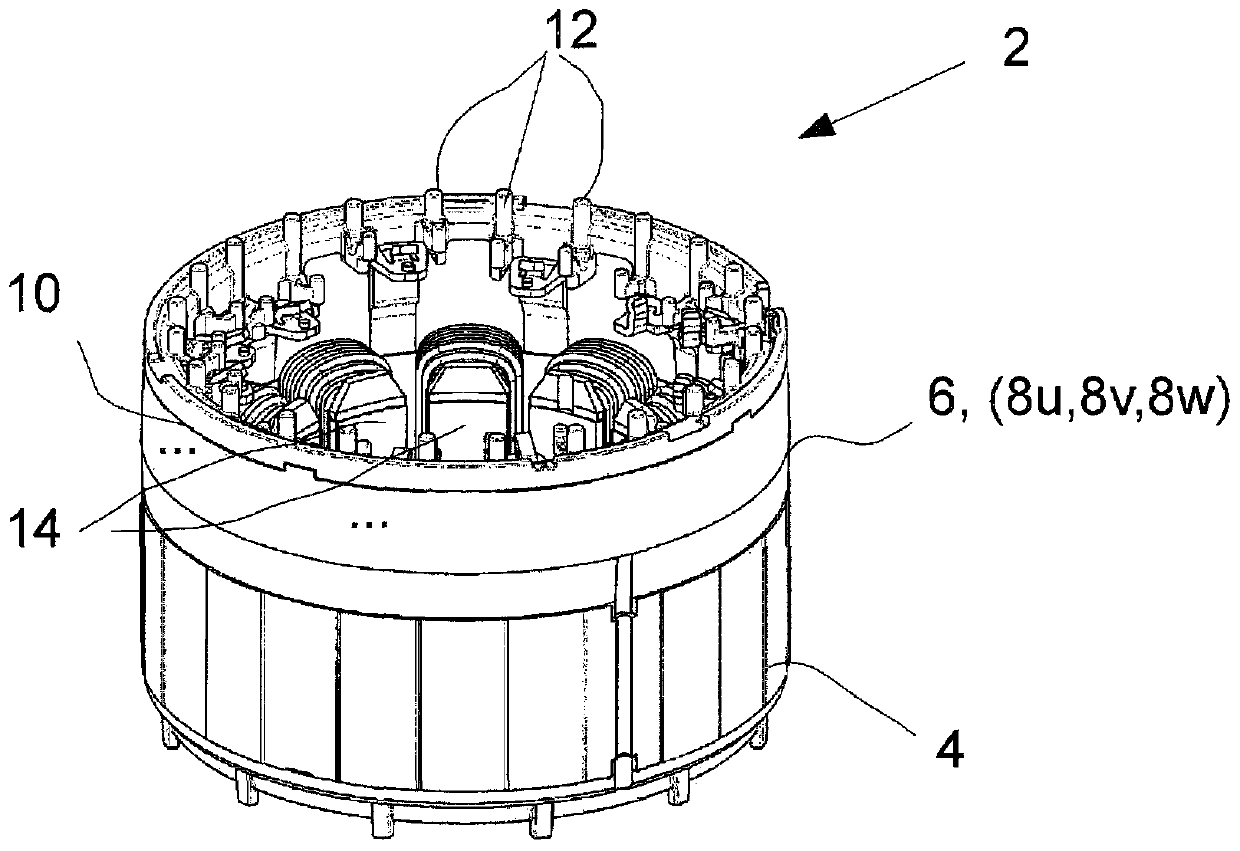

[0038] image 3 The stator arrangement 2 of the invention is shown in a perspective view, according to a first preferred embodiment of the invention, which employs a 12-pole solution for the inner rotor.

[0039] The main components of the stator arrangement 2 consist of a winding carrier 4 for accommodating the windings 1' to 12', a terminal disc 6 with terminal rings 8u, 8v, 8w embedded in an injection-molded encapsulation and on which guide pins 12 are formed The guide disc 10.

[0040] Twelve windings 1' to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com