A brushless motor for spray coater

A technology of brushless motors and spraying machines, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of space occupation, poor controllability of motors, unstable operation, etc., achieve small mutual inductance, increase speed, and benefit efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

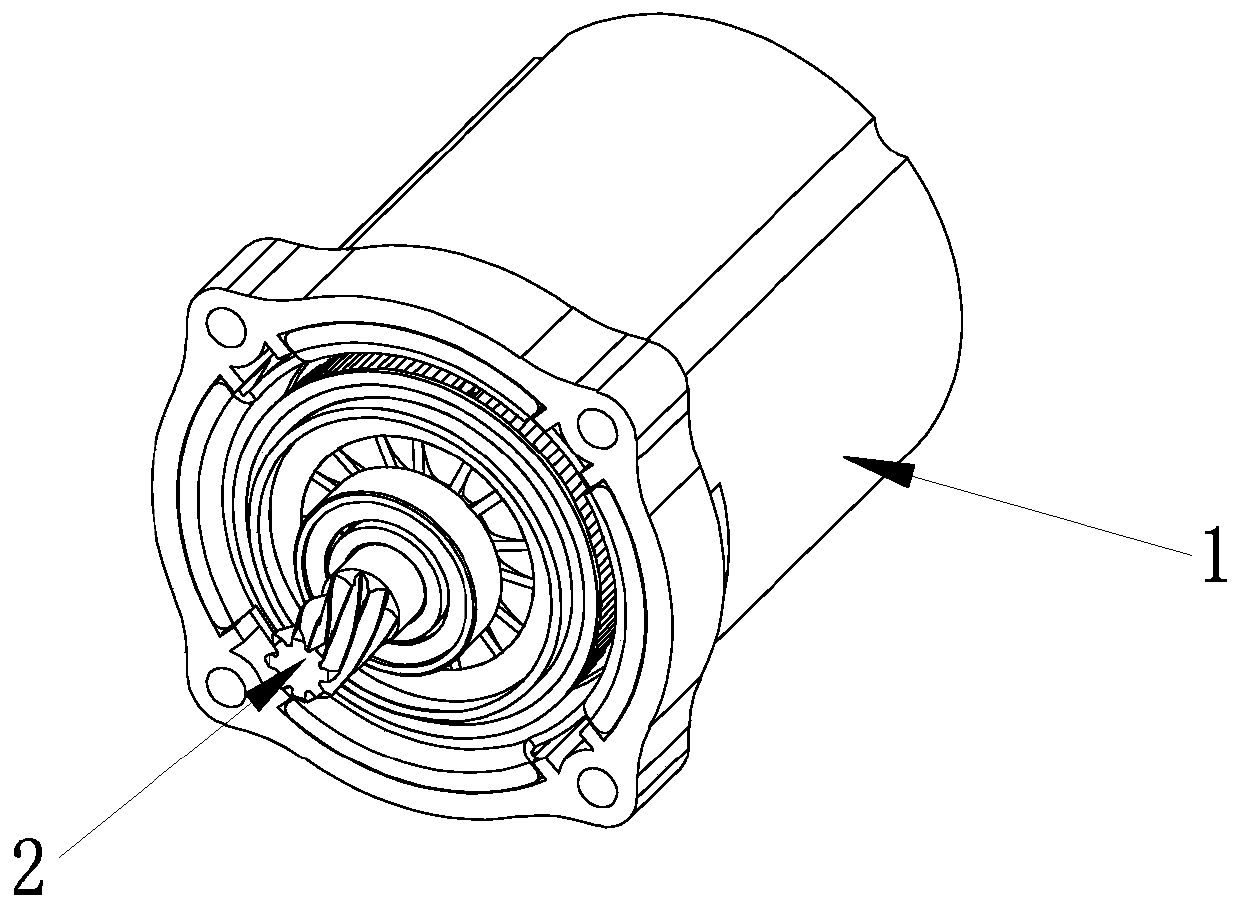

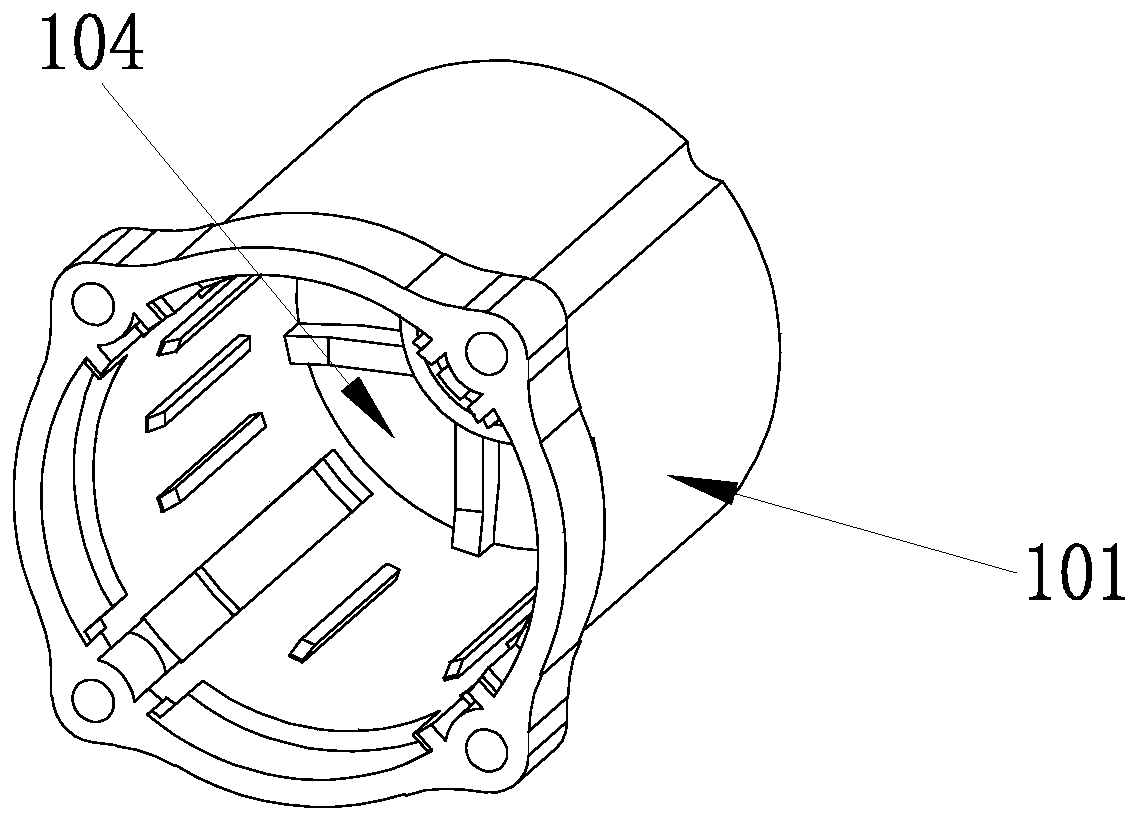

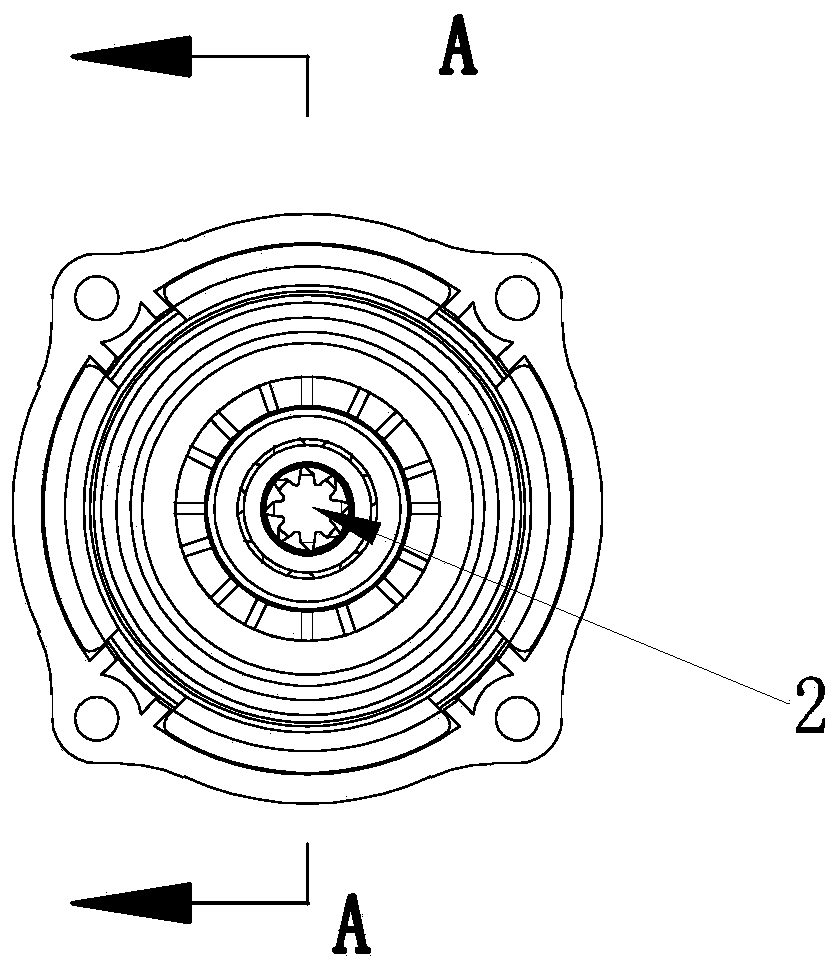

[0034] Such as Figure 1-7 As shown, a brushless motor for a spraying machine provided in this embodiment includes a casing 1, a motor shaft 2 and a stator assembly 4 arranged inside the casing 1; a rotor 3 is fastened on the motor shaft 2; the stator The assembly 4 is coaxially arranged with the rotor 3 and the stator assembly 4 is sleeved on the outside of the rotor 3; the stator assembly 4 includes a stator core 41 fastened on the inner wall of the casing 1, a Stator insulation layer 40; a shaft hole is formed on the stator insulation layer 40, and the rotor 3 is located in the shaft hole; the brushless motor of the present invention has the advantages of simple and compact structure and convenient installation; the stator assembly includes a fastening The stator core on the inner wall of the casing and the stator insulation layer sleeved in the stator core have the advantages of convenient installation; compared with the traditional brushless motor, the structure of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com