Electric brush pressure self-adjusting conductive slip ring structure

A conductive slip ring, brush pressure technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of long product development, design and finalization cycle, difficulty in meeting the pressure requirements between slip rings, and limited pressure adjustment capabilities. Achieve the effect of improving life and contact reliability, improving shaping efficiency, and reducing installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

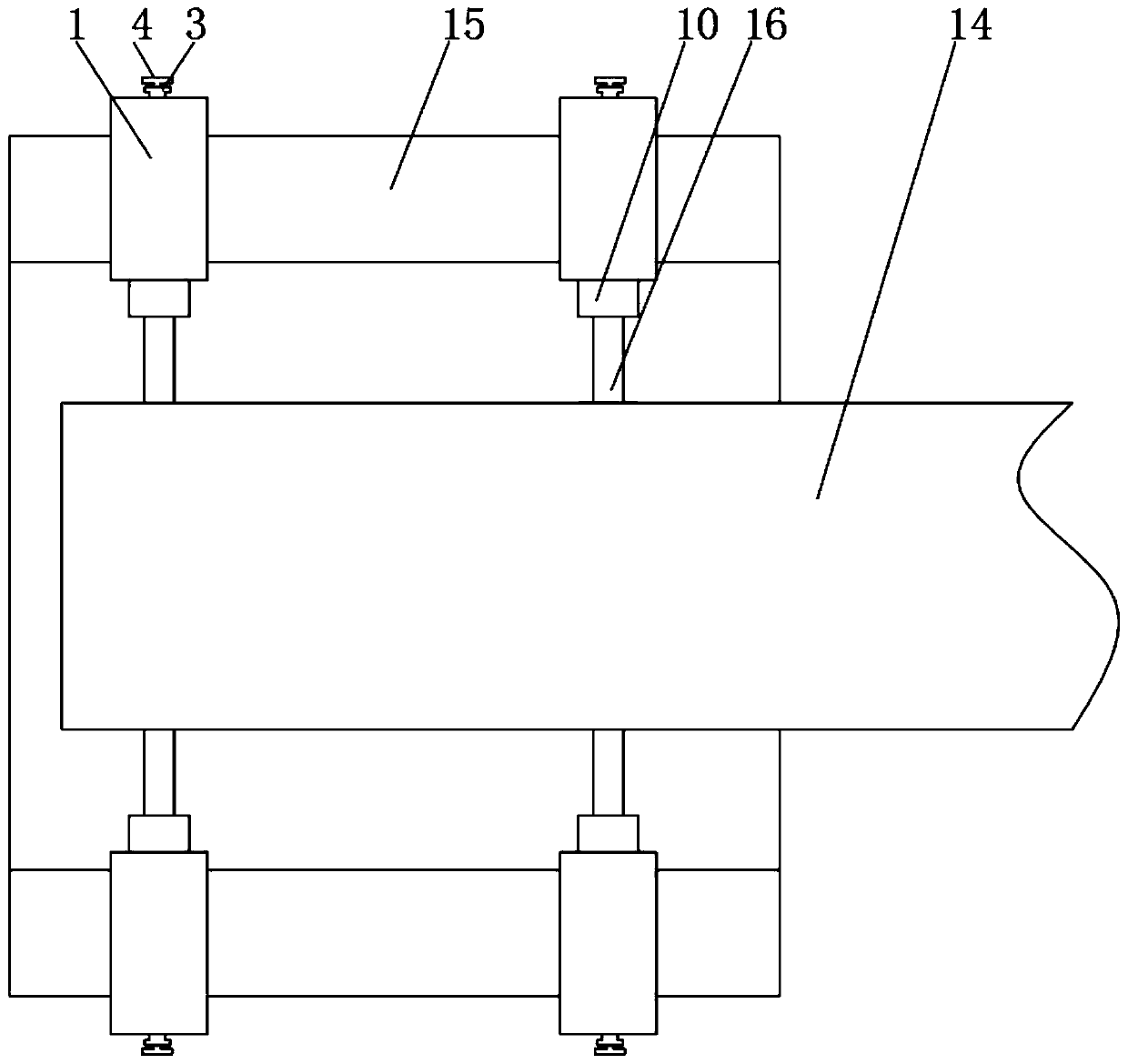

Embodiment 2

[0026] see Figure 5 , the difference from Embodiment 1 is that the brush 16 is tangent to the outer ring 14, one end of the brush 16 is hinged to the inner ring 15, and the adjustment arm 10 is against the middle of the brush 16, and the adjusting arm 10 is adjusted to the brush 16. The pressure determines the pressure between the brushes 16 and the outer race 14 .

[0027] Principle of work of the present invention and use process:

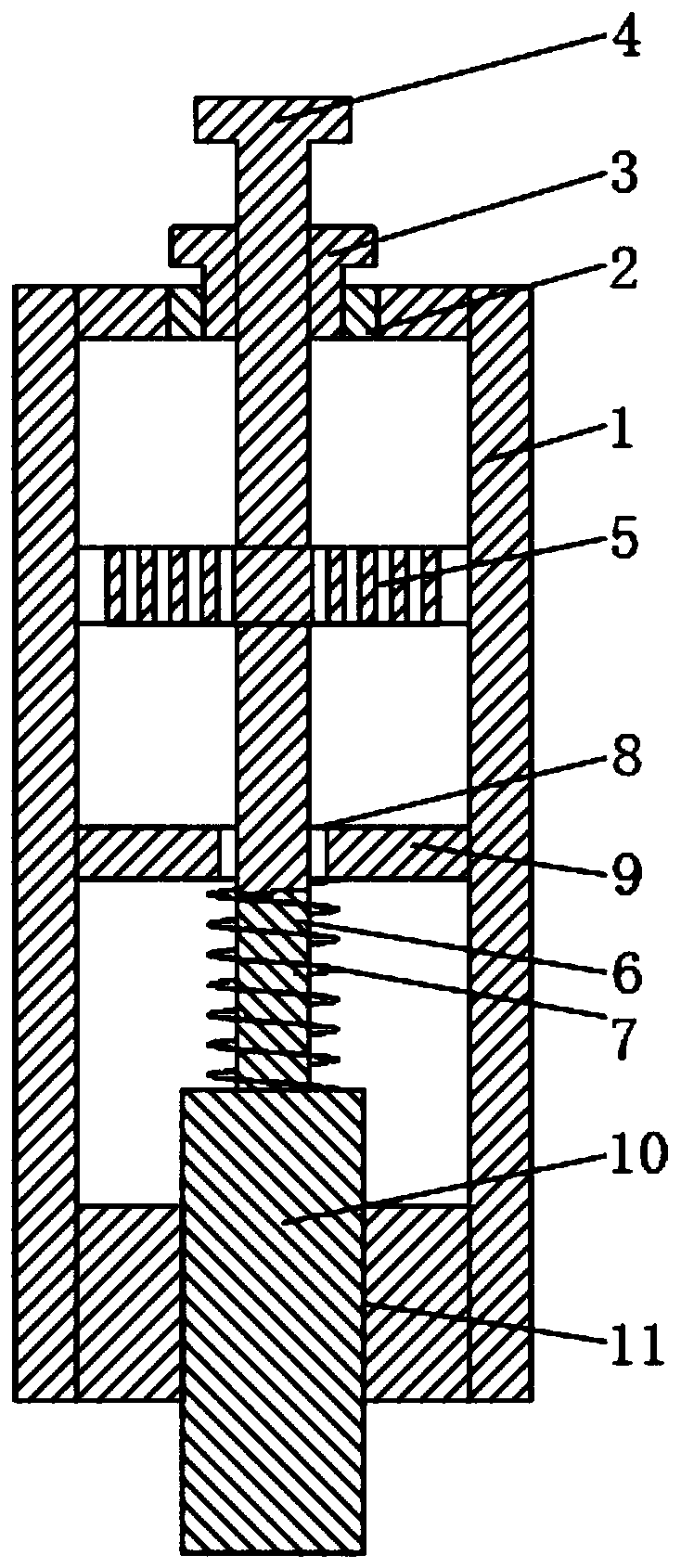

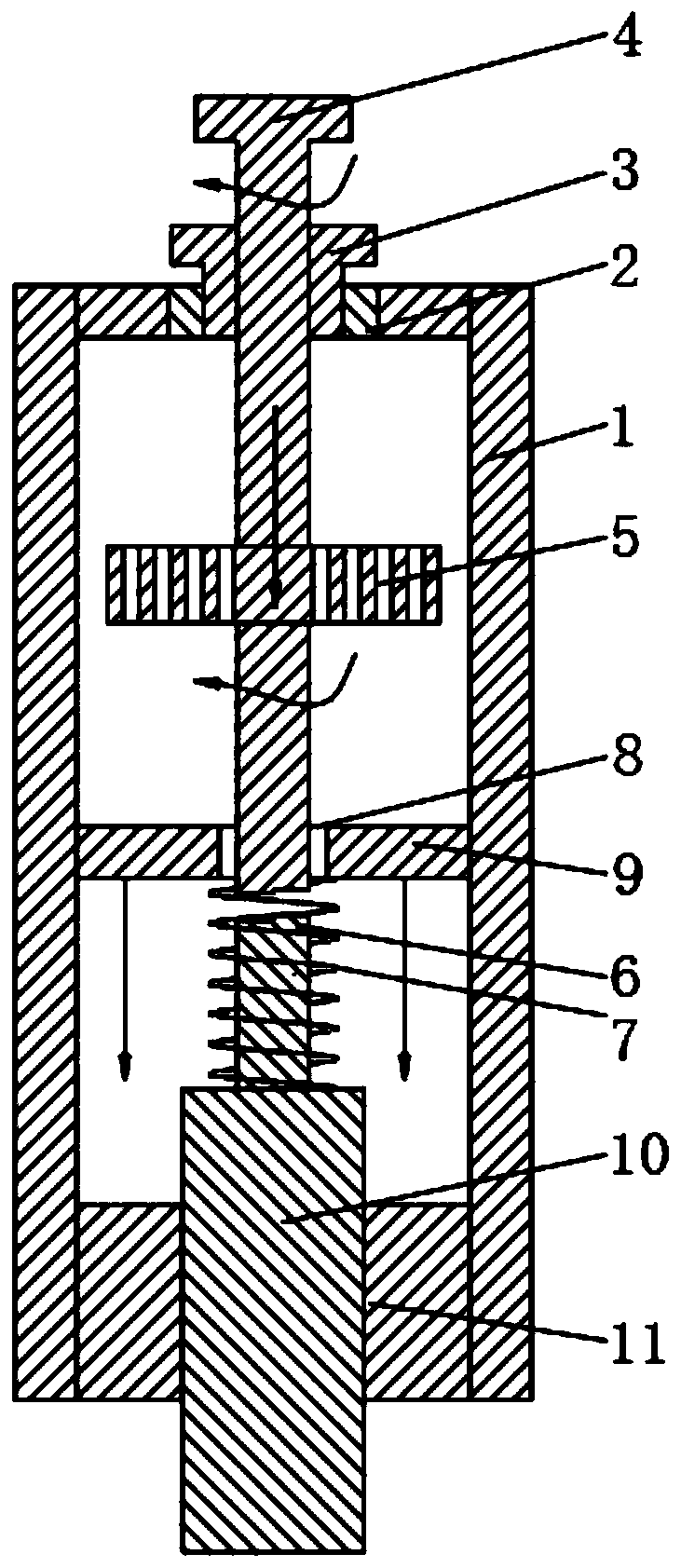

[0028] After the slip ring structure is fixedly installed as in Embodiment 1 or Embodiment 2, the upper end of the adjusting rod 4 is fixed, the threaded sleeve 3 is rotated, and the adjusting rod 4 is screwed into the fixing sleeve 1, and the adjusting rod 4 is compressed to fit the rod 6 and the sliding ring. Groove 7, the initial pressure between the holding brush 16 and the outer ring 14. At this time, since the threaded sleeve 3 can slide up and down in a small range, under the action of the matching rod 6, the adjustment rod 4 and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com