Multiphase flow multiphase visual corrosion test device and method

A corrosion test, multi-phase technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of difficult observation of liquid deposition and sulfur particle precipitation in the pipe, change of flow field in the pipe, influence of fluid flow, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clear understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings.

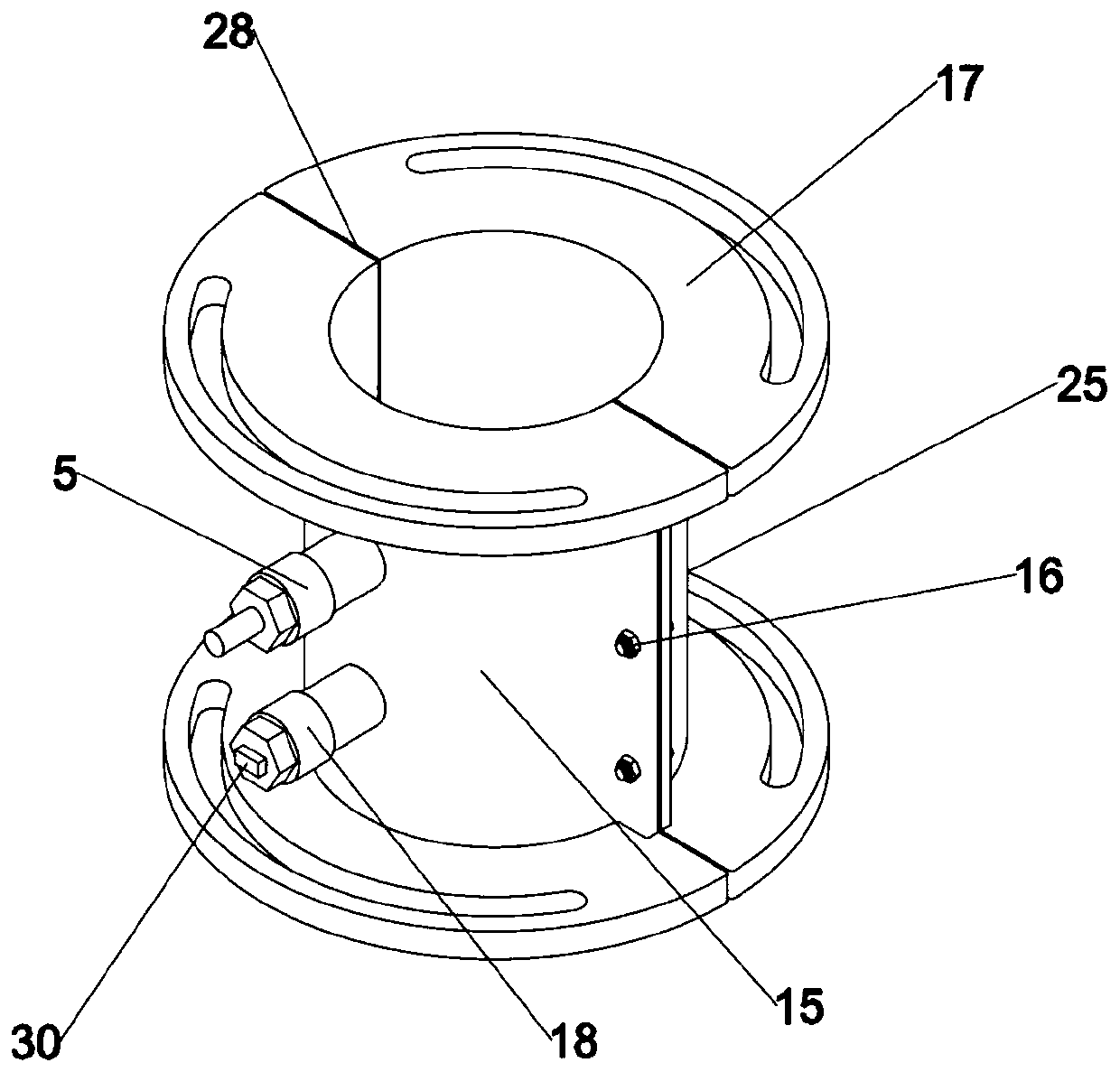

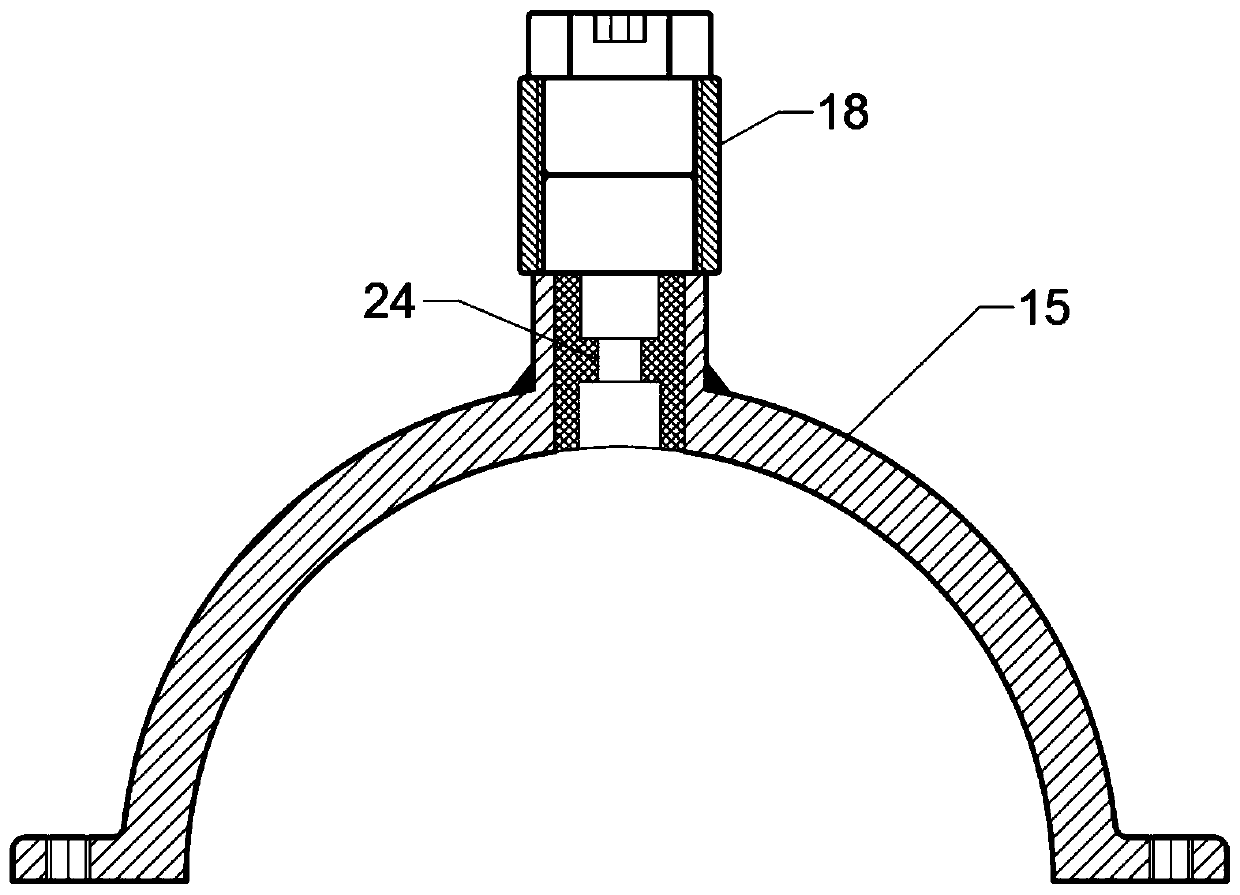

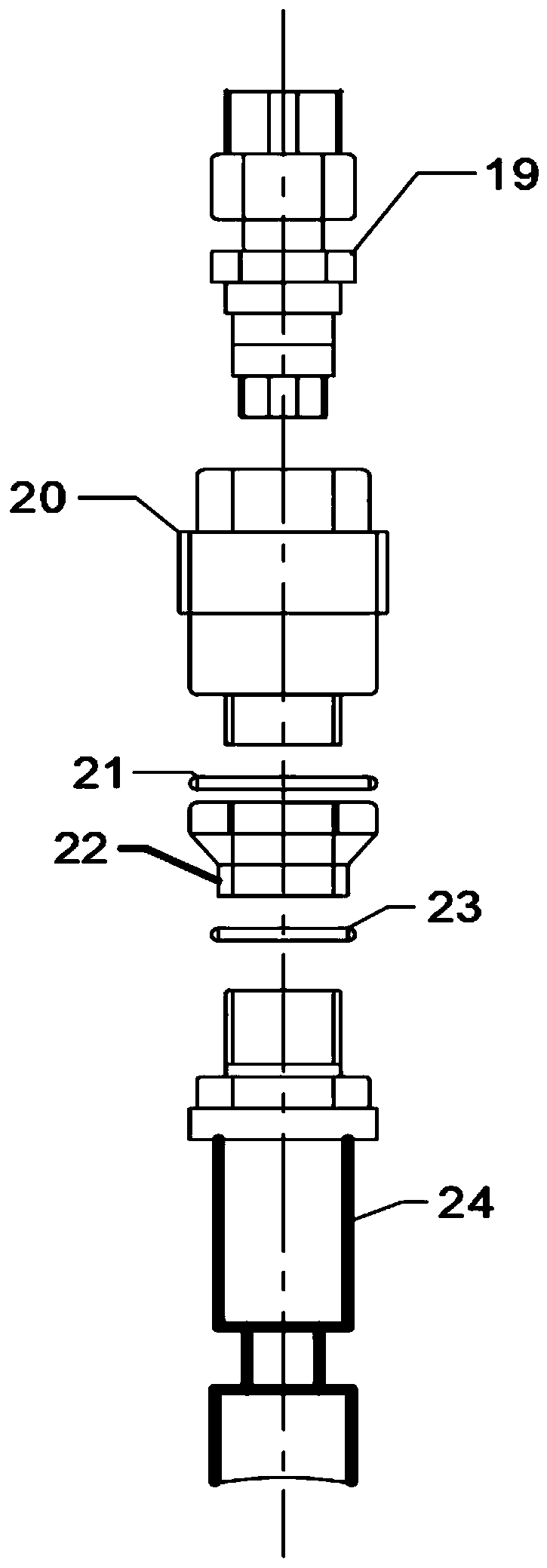

[0048] A multiphase flow multiphase visual corrosion test device, such as figure 1 As shown, it includes an open flange 17, screws 16, a resistance corrosion monitoring probe 5, a flat-head disc type hanging piece 30, a connecting sleeve 18, a corrosion monitoring unit 15, a visualization unit 25, a corrosion monitoring unit 15 and a visualization unit 25 It is connected by 6 screws 16, and a sealing gasket 28 is added in the middle. The upper and lower plates of the open flange 17 are provided with openings in the range of 30 degrees to 150 degrees. The openings are connected with ordinary flanges of pipelines. The corrosion monitoring phase area 4 is The opening of the installation flange in the range of 30° to 150° can place the resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com