Productivity prediction model and productivity sensitivity analysis method for multi-section fractured horizontal well in low-permeability tight gas reservoir

A technology of sensitivity analysis and prediction model, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of error, pressure can not be transmitted to the boundary and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

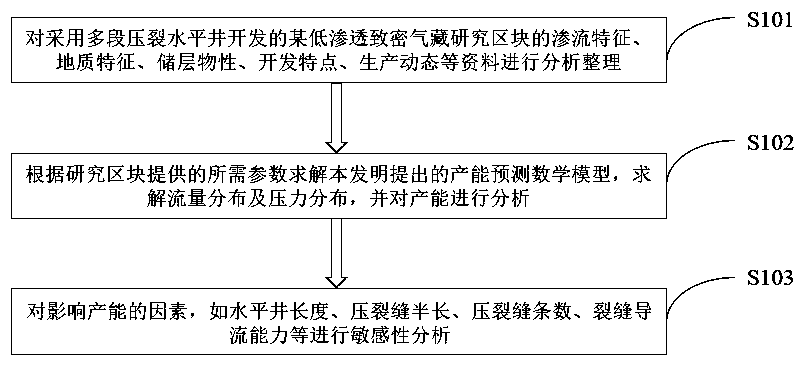

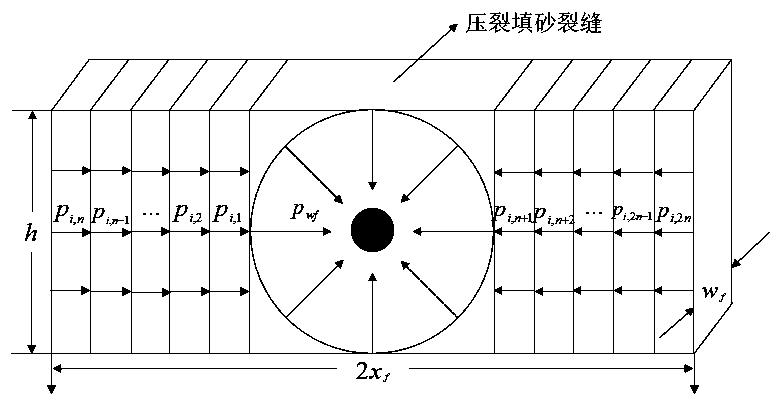

Method used

Image

Examples

Embodiment 1

[0270] Embodiment 1, taking Well X as an example, analyze the calculation process of the method:

[0271] In a tight sandstone gas reservoir, Well X is one of the fractured horizontal wells. The drilling depth of the well is 4319m, the length of the horizontal section is 824m, and 5 stages are completed through staged fracturing. There are four fracturing fractures on the horizontal section, and the intervals are 100m, 115m, 120m, and 160m. After the well was put into production, the corrected isochronous productivity well test was carried out. The results showed that the open flow rate of Well X was 85.04×10 4 m 3 / d. The basic parameters of the gas reservoir and the analysis results of the pressure recovery well test are shown in the table.

[0272] Table 1X well pressure recovery time interpretation results

[0273]

[0274]

[0275] Enter the required parameters into the following formula:

[0276]

[0277] The model in this paper calculates the open flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com