Device for utilizing desulfurization waste liquid and operation method thereof

A technology of desulfurization waste liquid and operation method, applied in separation methods, steam generation methods, chemical instruments and methods, etc., can solve problems such as environmental pollution and poor sales, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

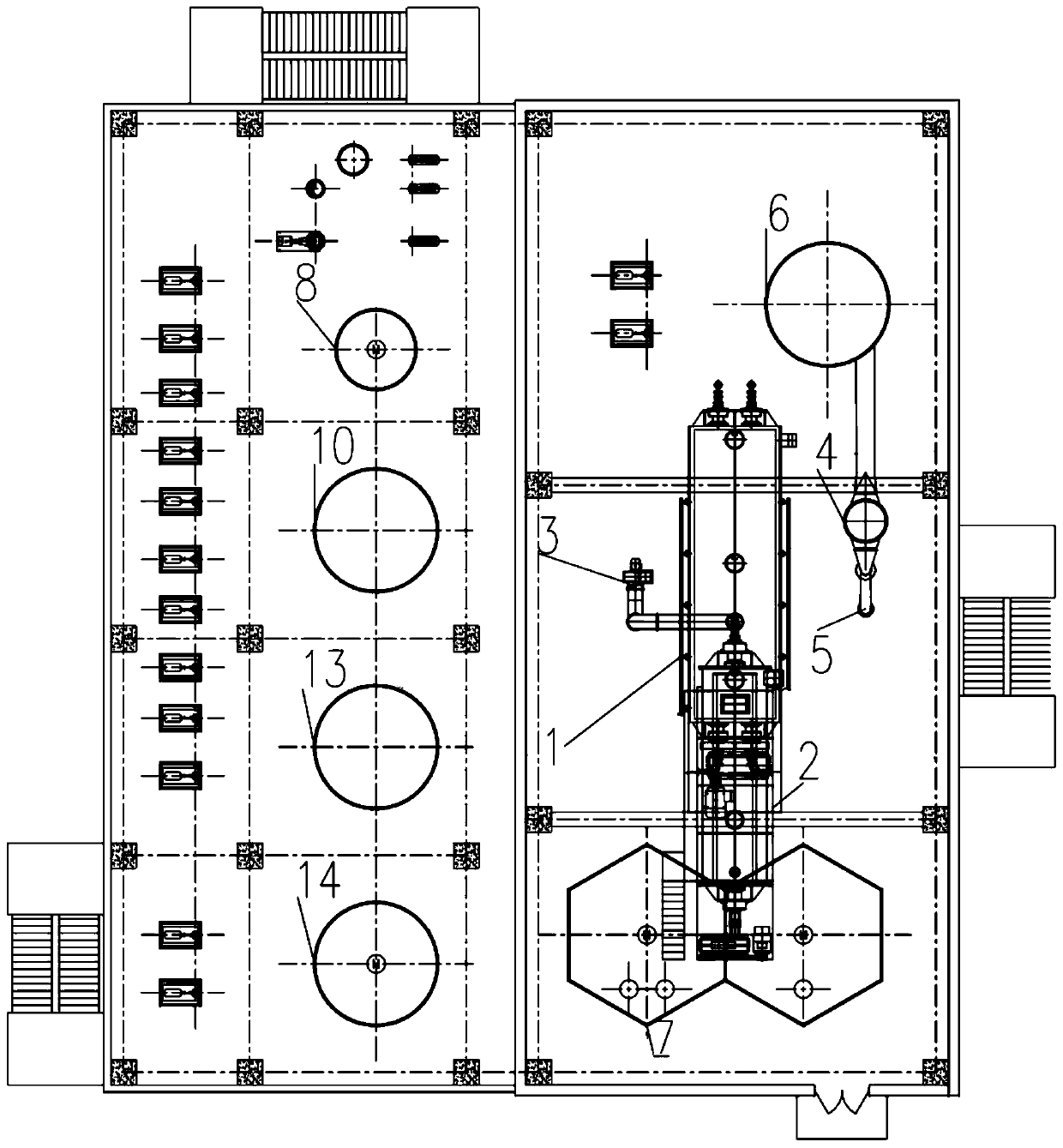

[0060] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

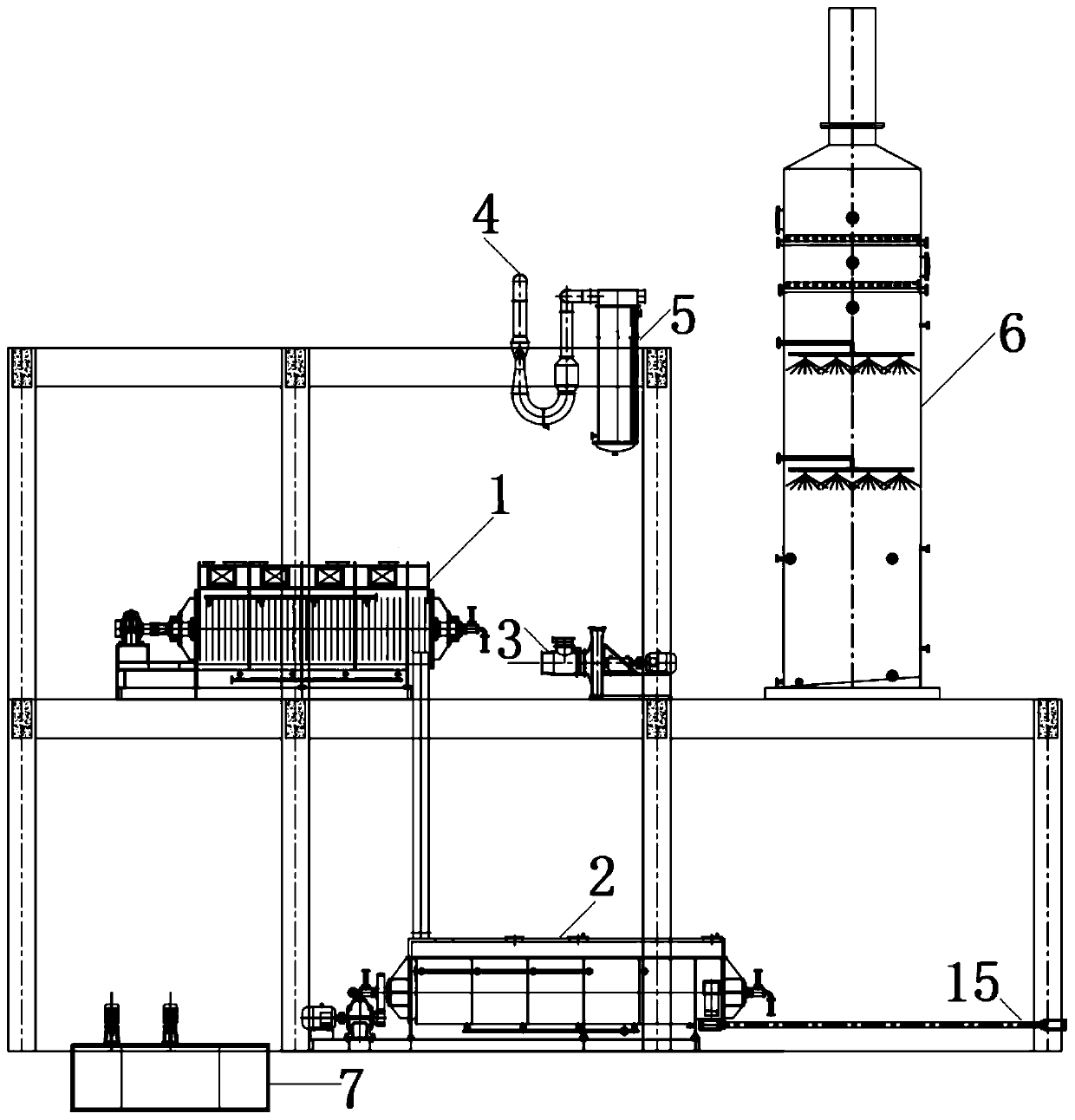

[0061] refer to Figure 1-Figure 7 ,in, figure 1 This is the elevation of the drying and curing and exhaust gas section of the device, which mainly reflects the relationship and relative position of each equipment floor, as well as the direction of main materials in the section. The structure of this area is a two-story frame structure above the ground, and an underground regulating pool is set underground. The produced products are delivered to the sulfur burning section through the conveyor 15 after being output by the second dryer 2 . This section is connected with the sulfur burning section.

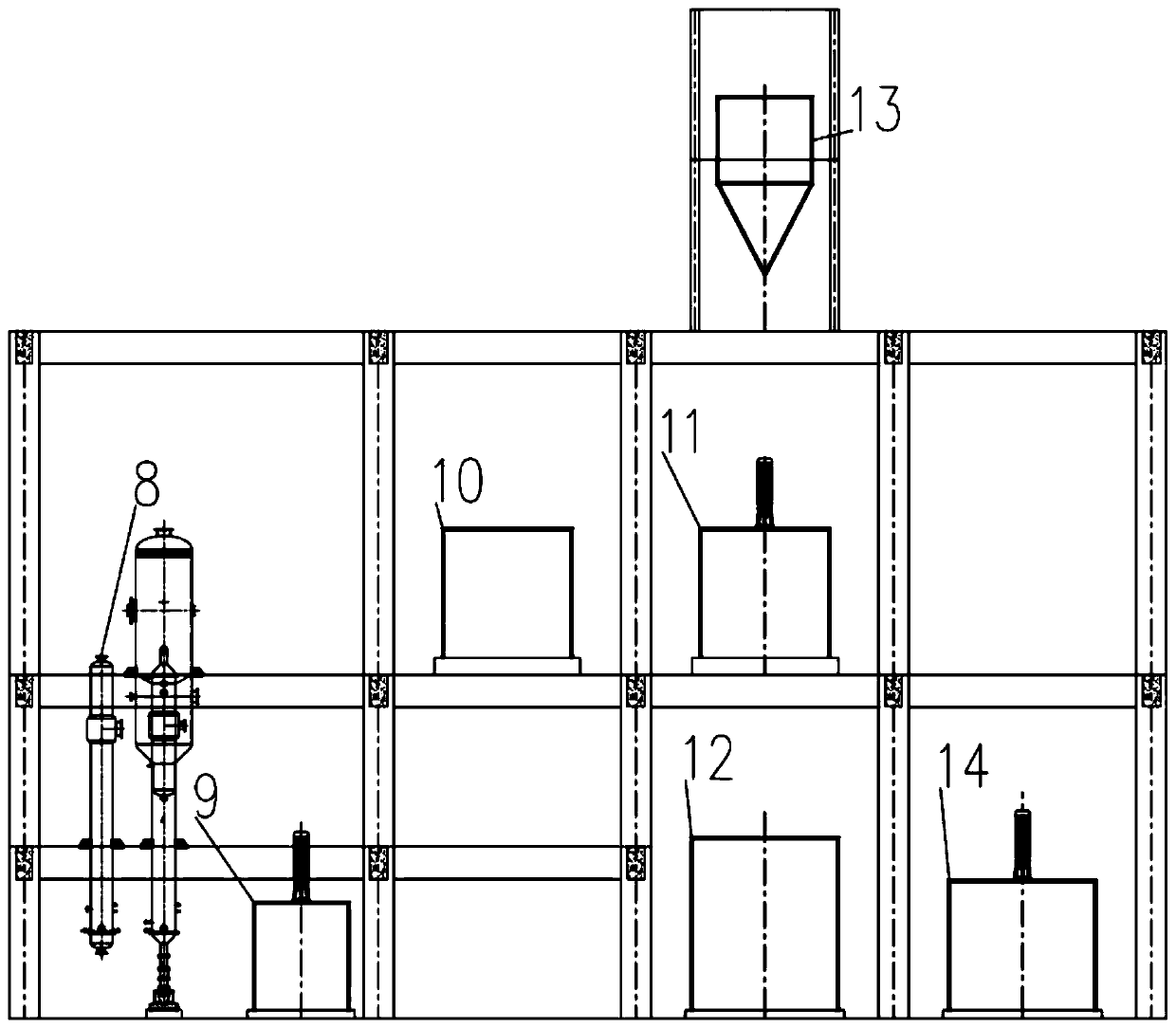

[0062] figure 2 This is the elevation of the pretreatment gas section of the device, which mainly reflects the relationship and relative position of each equipment floor, as well as the direction of main materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com